Expansion flexible pipe joint

A flexible pipe and pipe shaft technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, passing element, etc., can solve the problems of poor fixing operation, cutting workability, etc., and achieve good workability and reliable coating treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

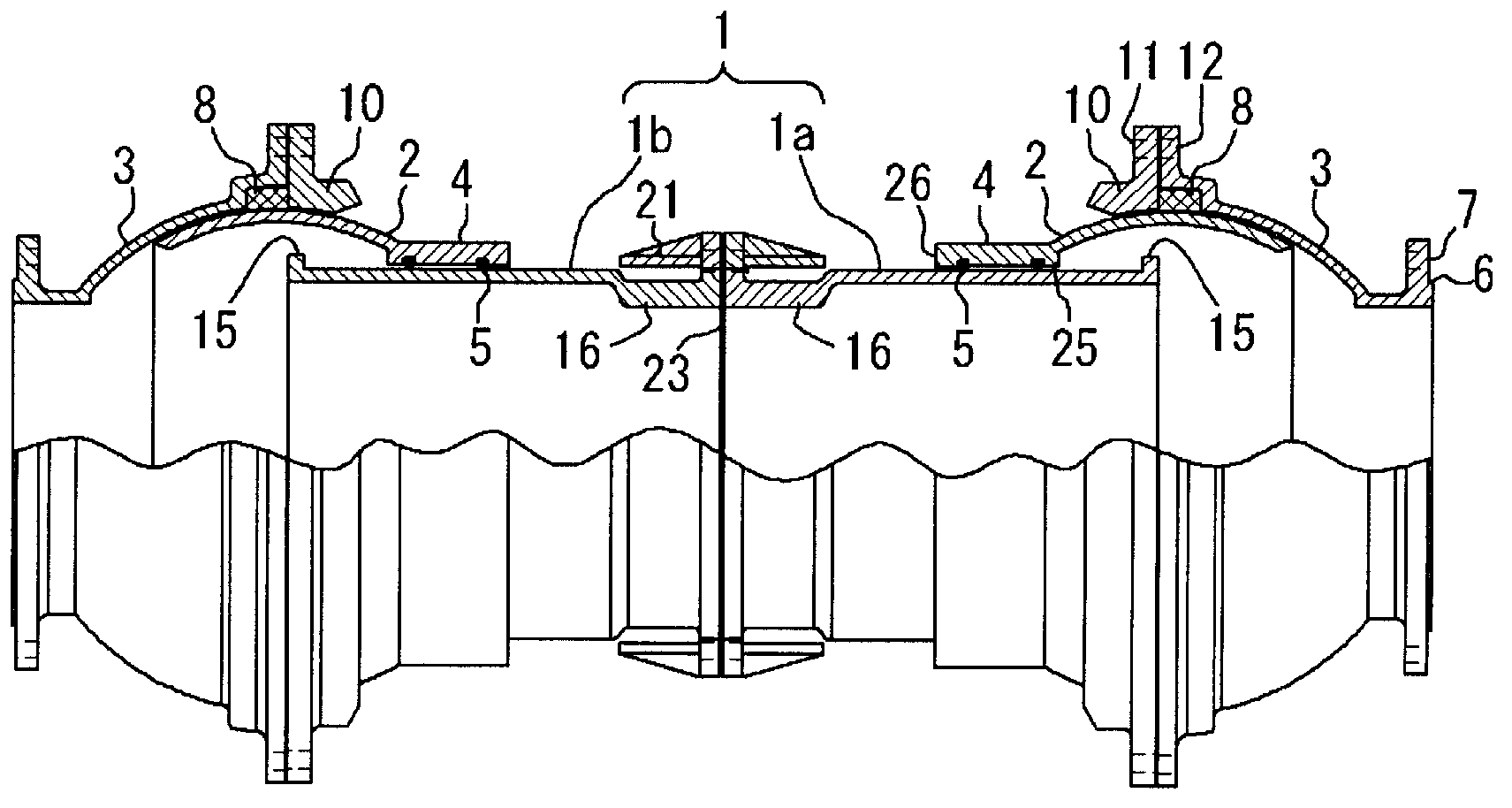

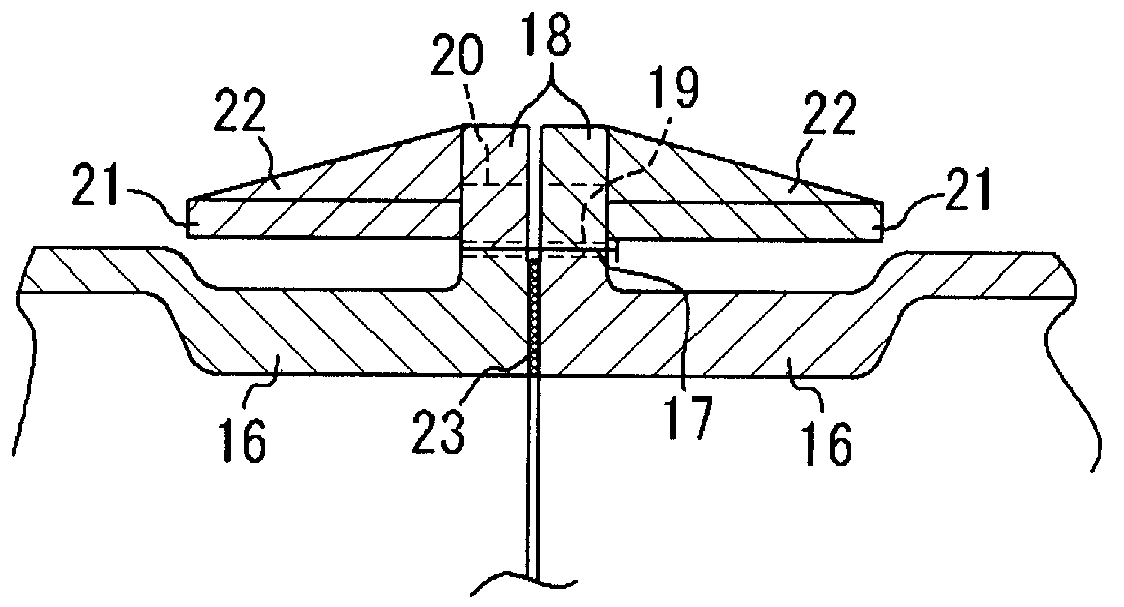

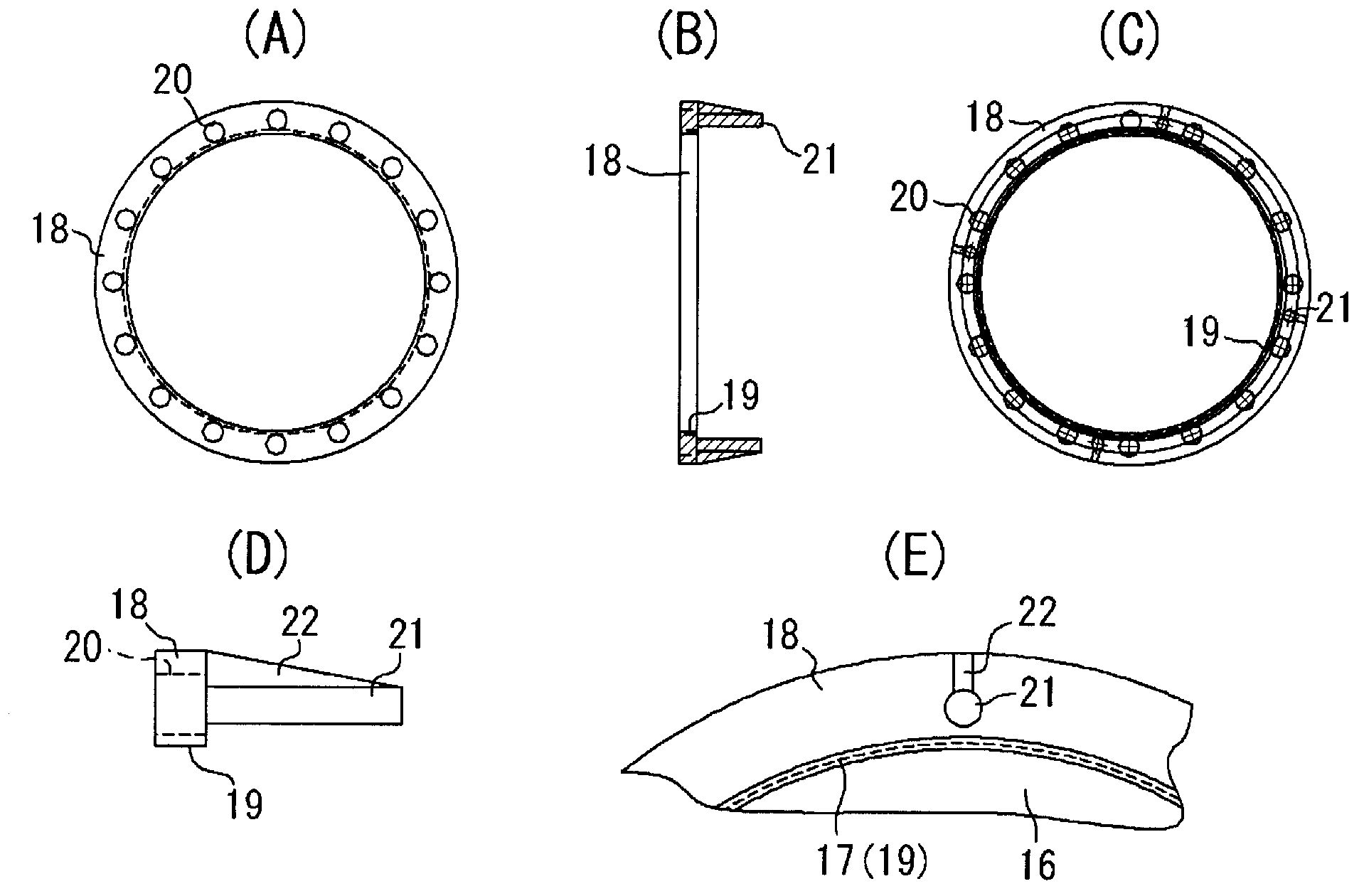

[0041] figure 1 It is a broken front view of the upper half of the telescopic flexible pipe joint. In this figure, 1 is a connecting pipe, which is composed of a pair of single pipes 1a and 1b. 2 and 2 are a pair of rotating spheres that are slidably fitted to both ends of the connecting pipe 1 in the direction of the tube axis, and a part of the outer peripheral surface is formed into a spherical surface, and 3 and 3 are inner peripheral surfaces arranged so as to become the same spherical surface. A pair of housings are in sliding contact with the outer peripheral surfaces of these rotating spheres 2 , 2 . On the other end of the rotating sphere 2,2 opposite to the housing 3,3, a short tubular sliding portion 4 extending in the axial direction is integrally provided, and the inner peripheral surface of the sliding portion and the outer peripheral surface of the connecting pipe 1 A plurality of O-rings 5 are disposed between them so as to fit in, for example, annular groov...

no. 2 Embodiment approach

[0051] Figure 6 The second embodiment of the present invention is shown, and since this embodiment has the same parts as those of the first embodiment, the same reference numerals are assigned to such parts to omit description, and the different parts will be mainly described.

[0052] In the first embodiment, the single pipes 1a and 1b of the connection pipe 1 are connected to each other, but in the second embodiment, between the single pipe 1a and the single pipe 1b of the connection pipe 1, there are further connections between the single pipe 1a and the single pipe 1b on the outer peripheral surfaces of both ends. There is an extension tube 28 with a flange on it. If such an extension pipe 28 is connected and used by the above-mentioned flange, the length of the connection pipe 1 can be further adjusted appropriately, and there is an advantage that the amount of displacement can be further increased. Furthermore, since the bolt hole 20 with the stopper flange 18 is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap