Substrate-free LED lamp and manufacturing method thereof

A technology for LED lamps and LED lamp beads, which is applied in lighting and heating equipment, point light sources, electric light sources, etc., can solve the problems of increasing the thermal resistance of LED lamp beads and supports, complex manufacturing processes, and high manufacturing costs. Save material and production cost, simple production process, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, specific purposes and functions of the present invention, and analyze the advantages and spirit of the present invention, the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments can be further understood.

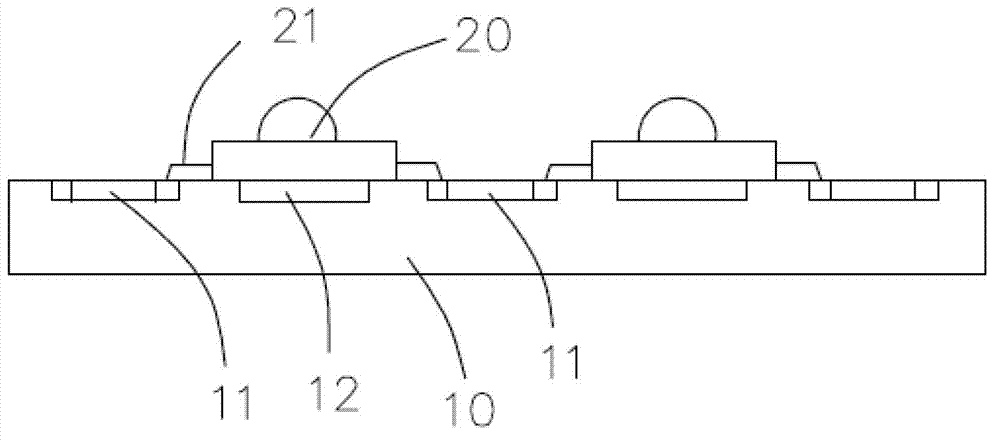

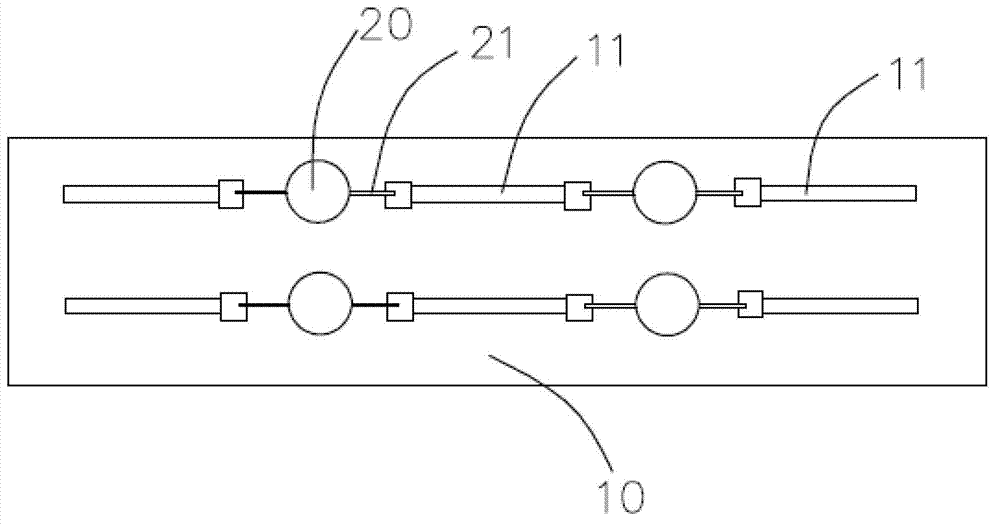

[0027] A substrateless LED lamp and a manufacturing method thereof include a base 10 and a plurality of LED lamp beads 20 arranged on the base 10 . The base 10 is provided with a metal plating layer a11 and a metal plating layer b12 , the metal plating layer a11 forms a circuit layer for conducting the LED lamp beads 20 , and the metal plating layer b12 forms a heat conduction layer. The pins 21 of the LED lamp beads 20 are welded on the metal plating layer a11 to form a conductive path with the metal plating layer a11. The bottom of the LED lamp bead 20 is in close contact with the metal plating layer b12 , so that the heat of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap