Shell for lighting device and lighting device with the same

A technology for lighting devices and shells, which is applied to cooling/heating devices of lighting devices, components of lighting devices, and damage prevention measures for lighting devices, etc., and can solve problems such as short circuit of LED light-emitting components, rust and corrosion of metal devices, etc. , to improve heat dissipation performance and reduce the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

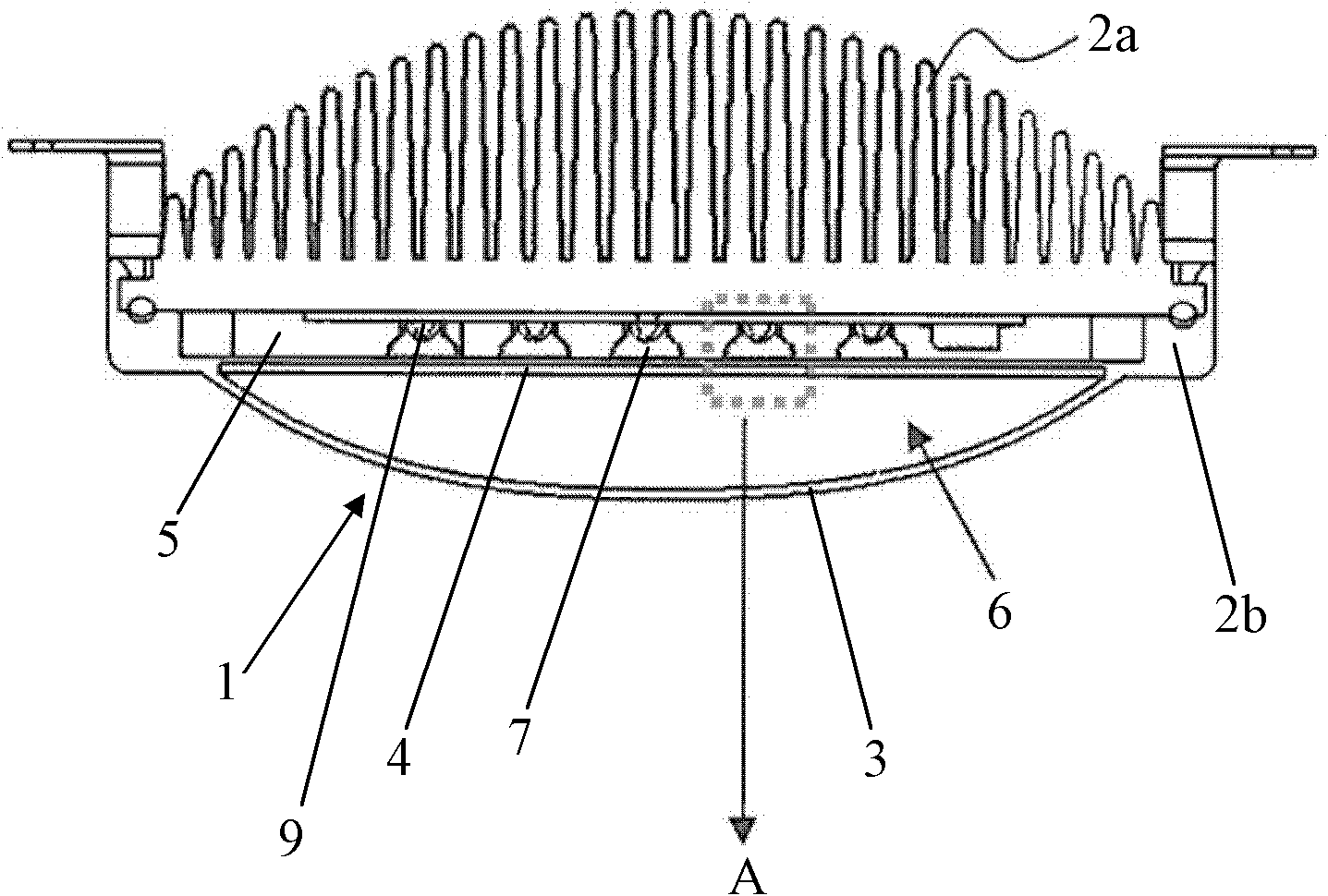

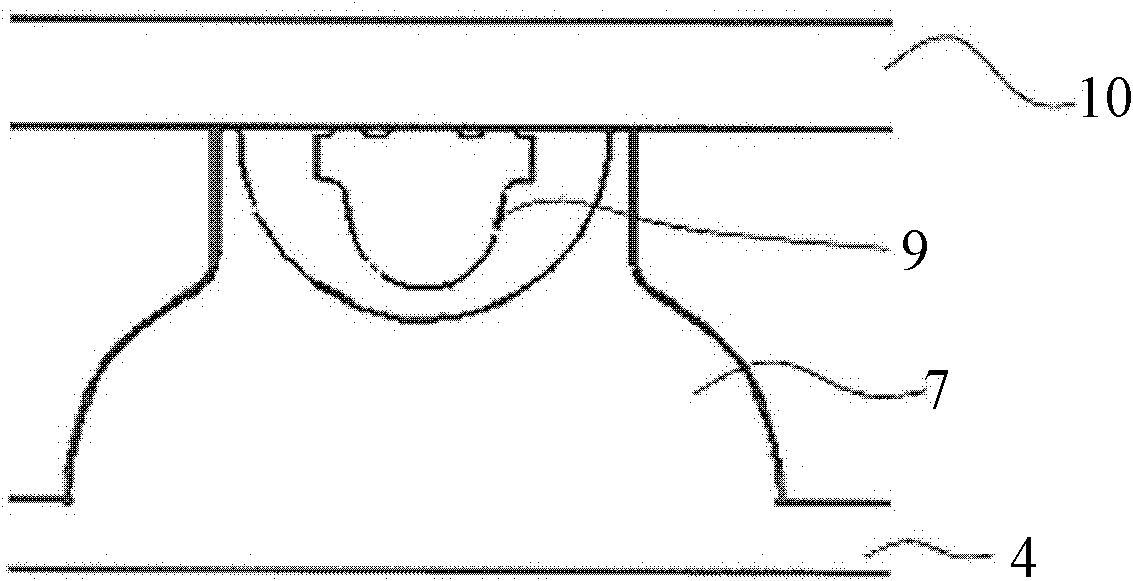

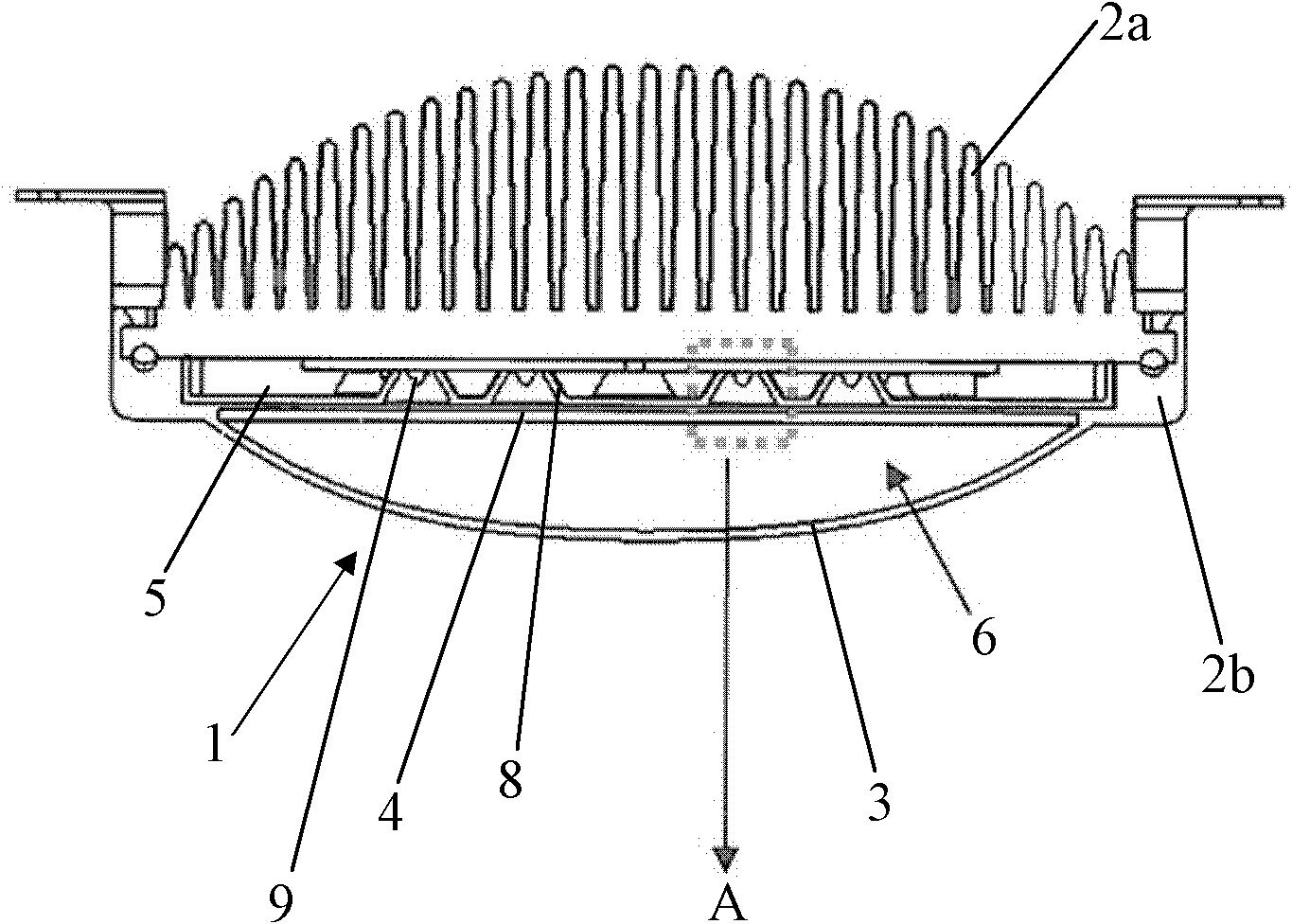

[0018] figure 1 A schematic view of a first embodiment of the housing according to the invention is shown. As can be seen from the figure, the housing 1 has two housing parts 2a, 2b, which are snapped together, wherein the housing part 2b is provided with a light-transmitting cover 3 and the housing The part 2a is designed as a heat sink, and the two housing parts 2a, 2b and the light-transmitting cover 3 jointly define a cavity. Further, it can be seen from the figure that a transparent partition 4 is arranged in the cavity, and the partition 4 separates the cavity into an assembly cavity 5 and an isolation cavity 6 which are sealed from each other, wherein a printed circuit board is arranged in the assembly cavity 5 10 and a plurality of light emitting components 9 and other devices installed on the printed circuit board 10. In this embodiment, the lighting device is designed as an LED lighting device, so LED chips, drivers and the like are arranged in the assembly cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com