Minitype airflow type gyro

An airflow type and gyroscopic technology, which is applied to steering sensing equipment and other directions, can solve problems such as hindering the flow of airflow beams, uneven dispersion of thermal elements 8, and reducing measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

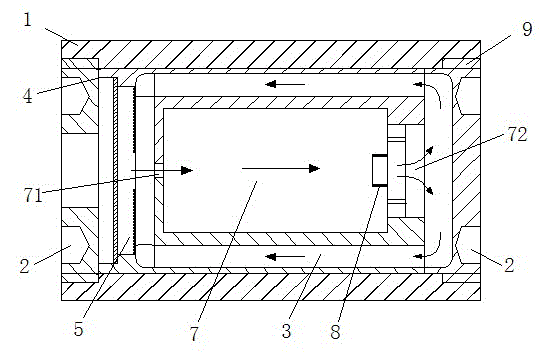

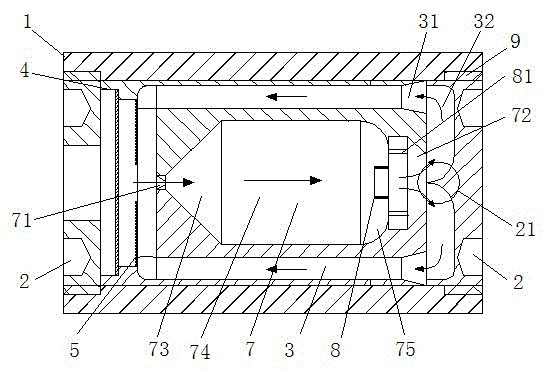

[0027] like figure 1 Shown is that the small air flow gyroscope of the present invention includes a housing 1, a disc spring 4, a piezoelectric pump 5, a test cavity 7, a thermal sensor 8 and a signal processing circuit (not shown in the figure); the housing 1 is composed of a side wall It is composed of end caps 2 covering both ends of the side wall. The side wall is thin-walled and cylindrical. The end cap 2 at one end is provided with an insulator for power supply wires and signal wires leading out of the signal outlet 9 of the housing 1. When the power supply and After the lead is drawn out, the signal lead-out port 9 is closed to make the inside of the housing 1 a closed space.

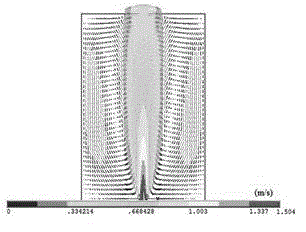

[0028] The test cavity 7 is arranged at the center position in the housing 1, and the left end of the test cavity 7 in the figure is provided with an air inlet nozzle 71, and the air inlet nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com