Manufacturing method for standard mass membrane used for beta-ray particulate matter calibration

A standard quality and production method technology, applied in particle suspension analysis, measuring device, suspension and porous material analysis, etc., can solve the problems affecting the measurement work efficiency, small purchase quantity, long time period, etc., and achieve convenient acquisition , low cost, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

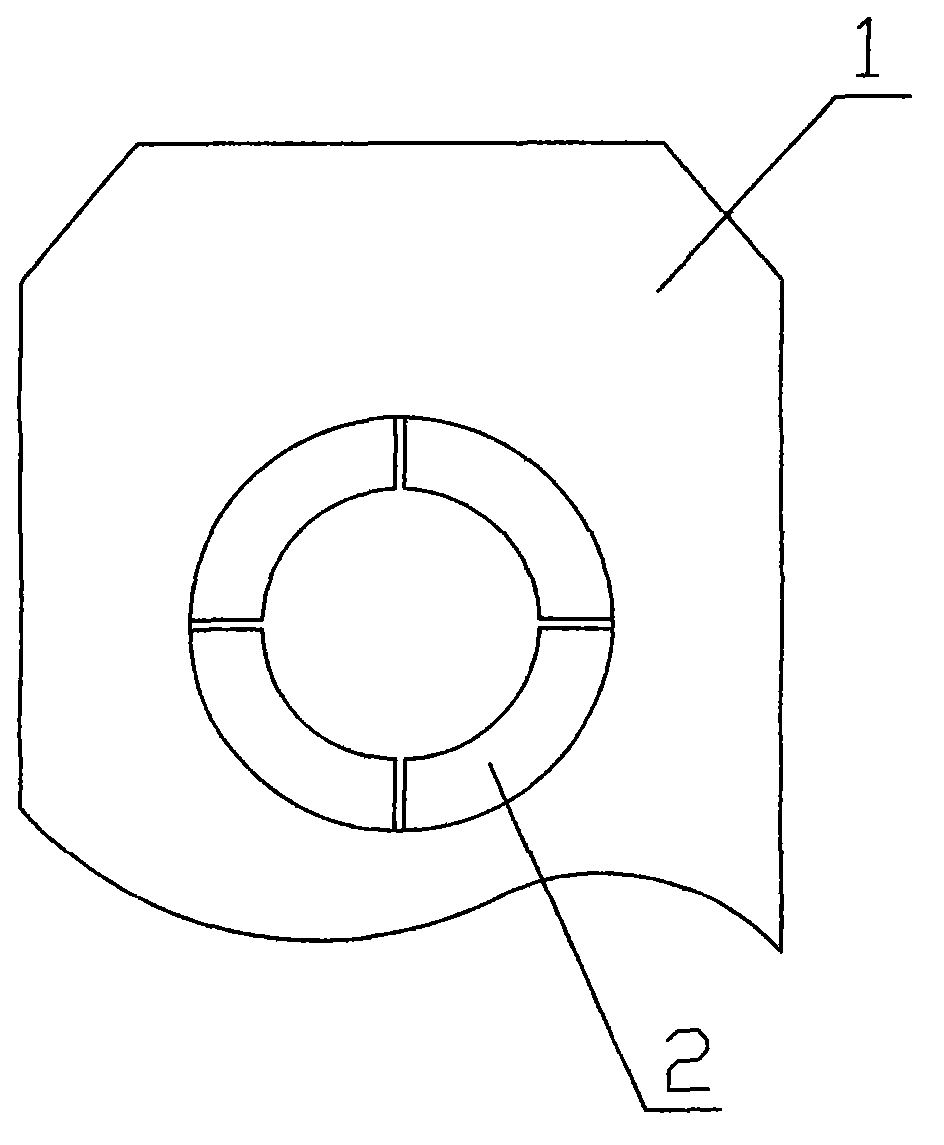

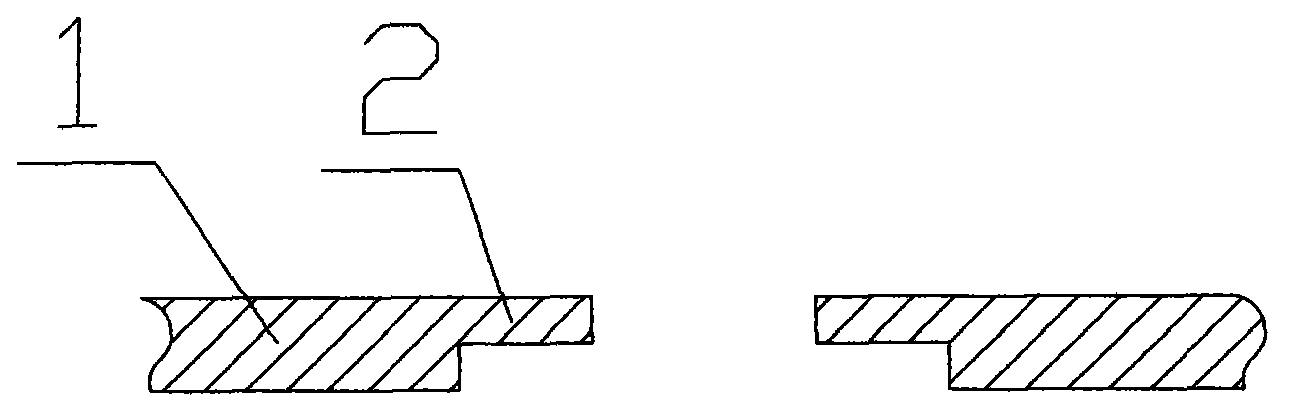

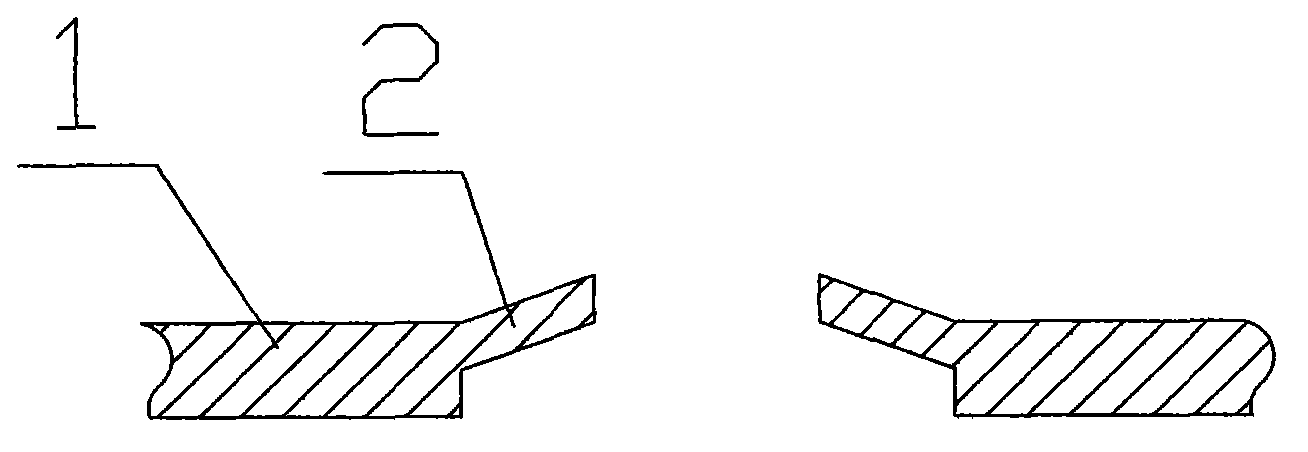

[0028] The invention relates to a method for making a standard quality diaphragm for calibrating particle matter in the beta ray method.

[0029] Select a 65μm optical polyester film, put the optical polyester film into a pure potassium hydroxide solution with a temperature of 60°C and a concentration of 6mol / L for etching, and etch the optical polyester film to 39±0.1μm by controlling the etching time , 44.7±0.1μm, 54.4±0.1μm thickness, the temperature is 60 ℃ and the concentration is 6mol / L pure potassium hydroxide solution has better etching effect and high etching efficiency.

[0030] Cut the optical polyester film into a suitable size diaphragm 4 using a circular mold, place the diaphragm 4 with a thickness of 44.7±0.1 μm and 54.4±0.1 μm between the radiation source and the detector for continuous testing for 4 minutes, and record the test For the obtained equivalent mass value, repeat the test 8 times to take the median value of the equivalent mass value, and use the med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com