Novel magnetic assembly and preparation method thereof

A magnetic component, a new technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnets, etc., can solve the problems of unsightly appearance, inconvenient processing, unsuitable application, etc., and achieve firm structure, small product thickness, and guaranteed performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

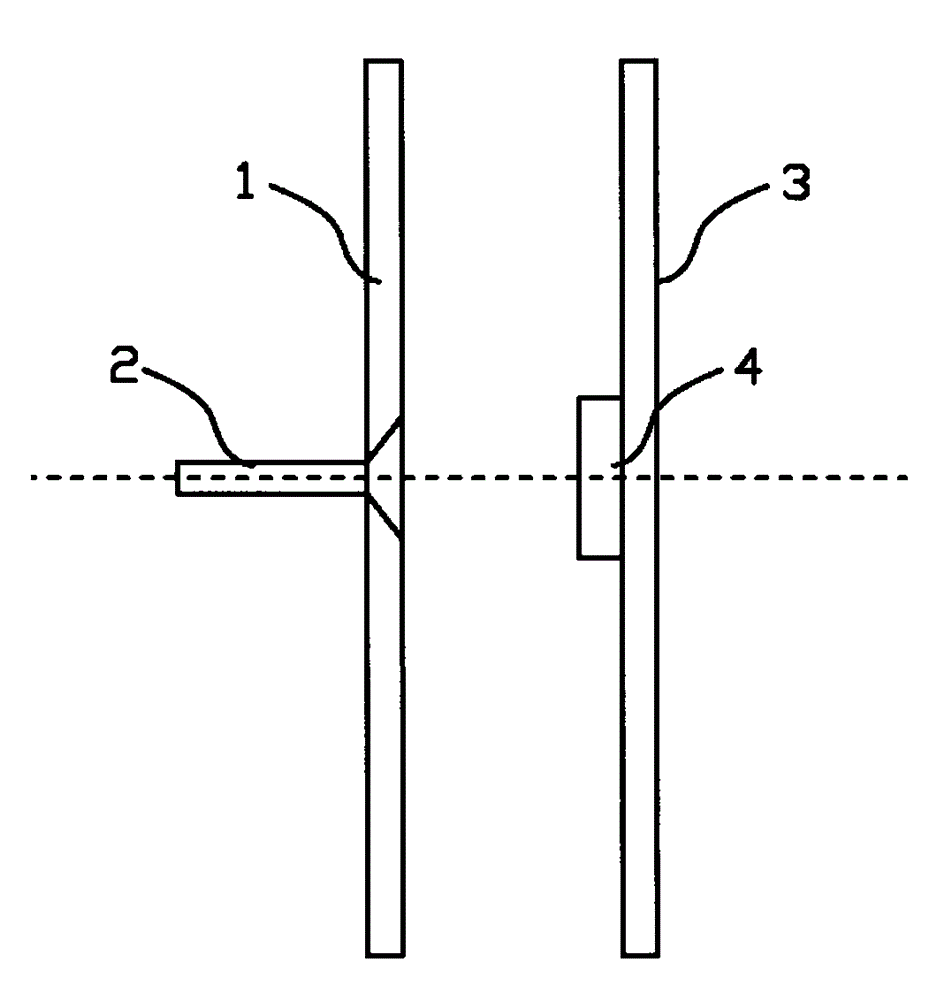

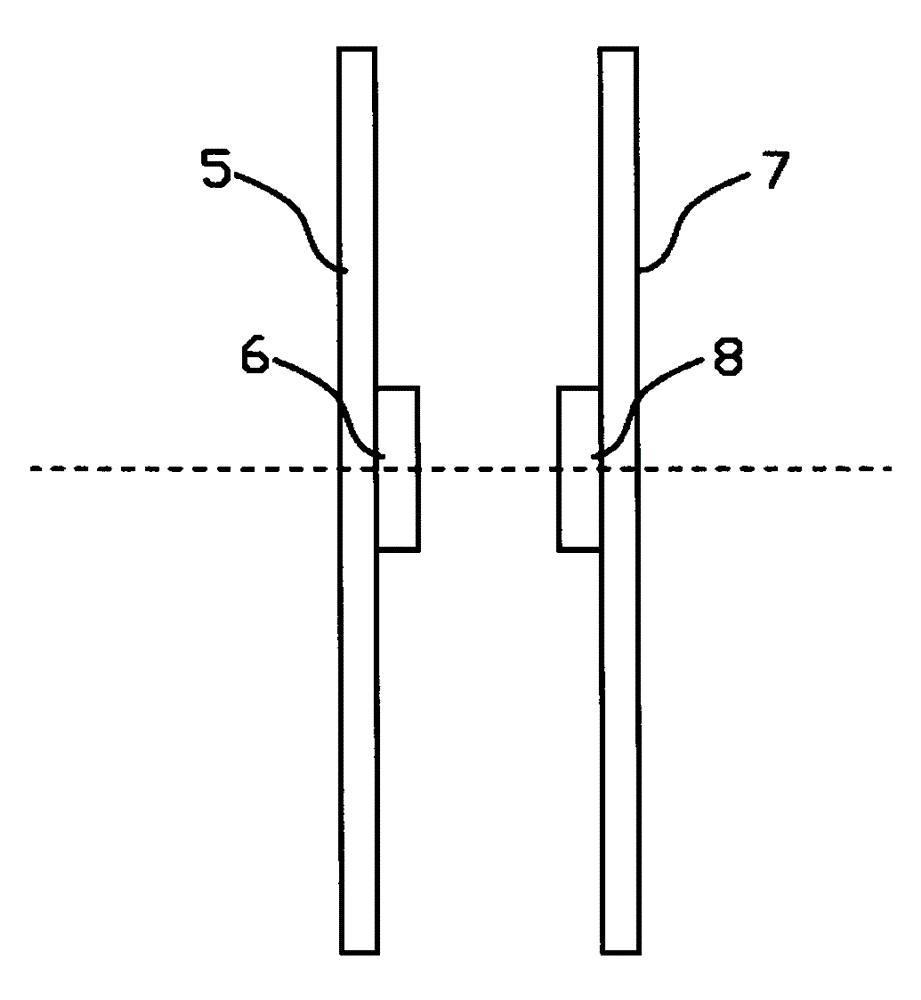

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and several preferred embodiments.

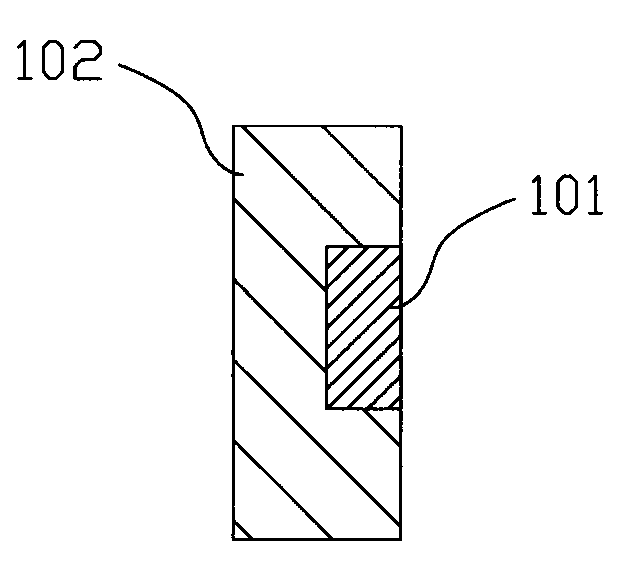

[0025] As one aspect of the present invention, the present invention provides a method for preparing a new type of magnetic assembly, which includes: taking iron powder and injecting it with injection molding equipment once to form a soft magnetic base material, and then injecting plastic material for a second time with injection molding equipment and covering it A plastic substrate is formed on the soft magnetic substrate, and at least one end surface of the soft magnetic substrate is exposed from one end surface of the plastic substrate.

[0026] Obviously, the aforementioned iron powder can be non-magnetic iron powder (eg, pure iron powder) or various types of magnetic iron powder.

[0027] Considering the needs of actual production, the present invention preferably adopts non-magnetic iron powder, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com