A push-pull type anti-spray and feces collection device

An anti-reverse spray, push-pull technology, used in transportation and packaging, vehicle sanitary equipment, sanitary equipment, etc., can solve the problem of easy leakage of large dirt tanks and valve bodies, increase in gas consumption, electricity consumption, and weight of toilet collection devices large and other problems, to achieve the effect of anti-reverse spray effect, simplified structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be used herein, not to be construed as limiting the invention.

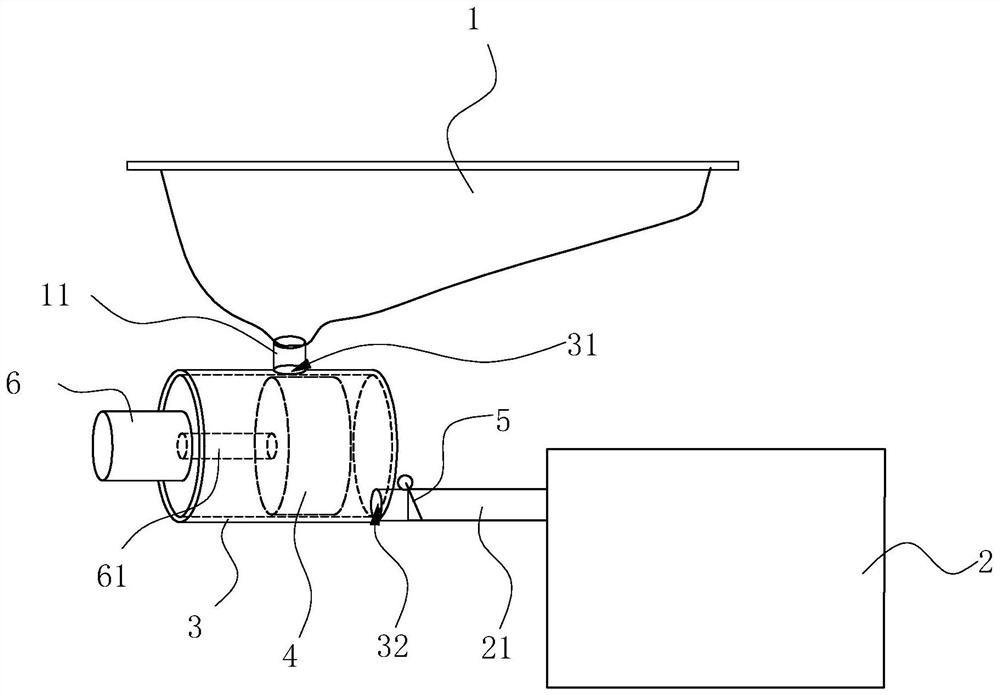

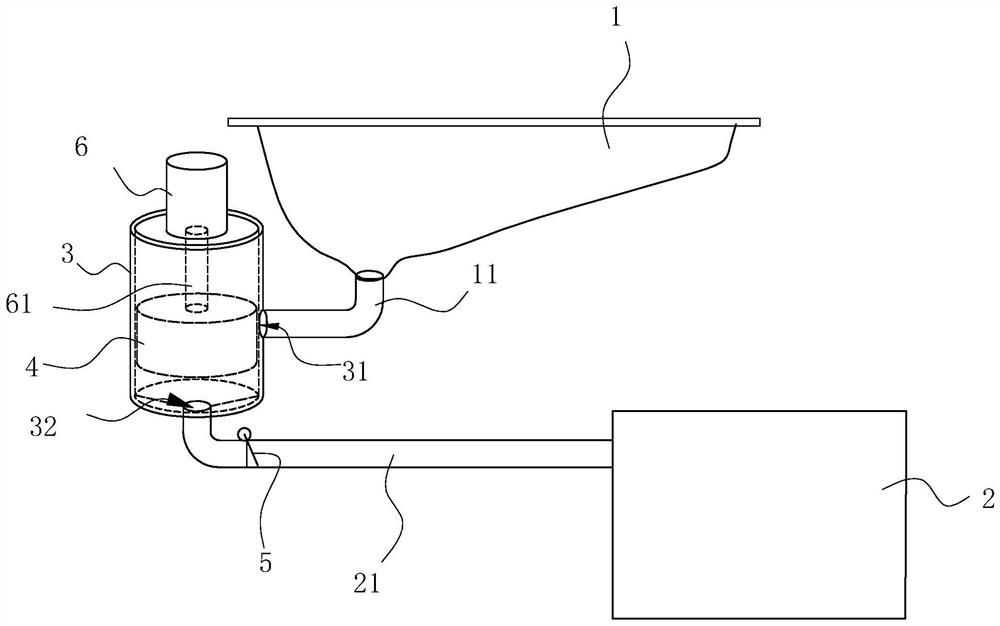

[0019] Such as figure 1 A schematic structural diagram of the assembled device of the present application, as shown, the push-pull anti-reverse retractable device, including the casing 1 and the large sludge box 2, the lower end of the casing 1 is connected to the lower end, large sludge box 2 Connecting a sewage pipe 21, further comprising a cylinder 3, a piston 4 provided in the cylinder 3 and sealing the cylinder 3 cavity, driving the piston 4, axially moving a drive mechanism and a sewage tube 21 One-way valve 5; one end of the cylinder 3 is provided with a sewage port 32 coupled to the sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com