A circuit board and shell plug-in connection structure and connection method

A connection method and connection structure technology, applied in the direction of electrical component connection, conductive connection, printed circuit components, etc., can solve the problems of inconsistent thermal expansion and contraction, product connection failure, welding open circuit, etc., to achieve reliable and stable connection, avoid The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

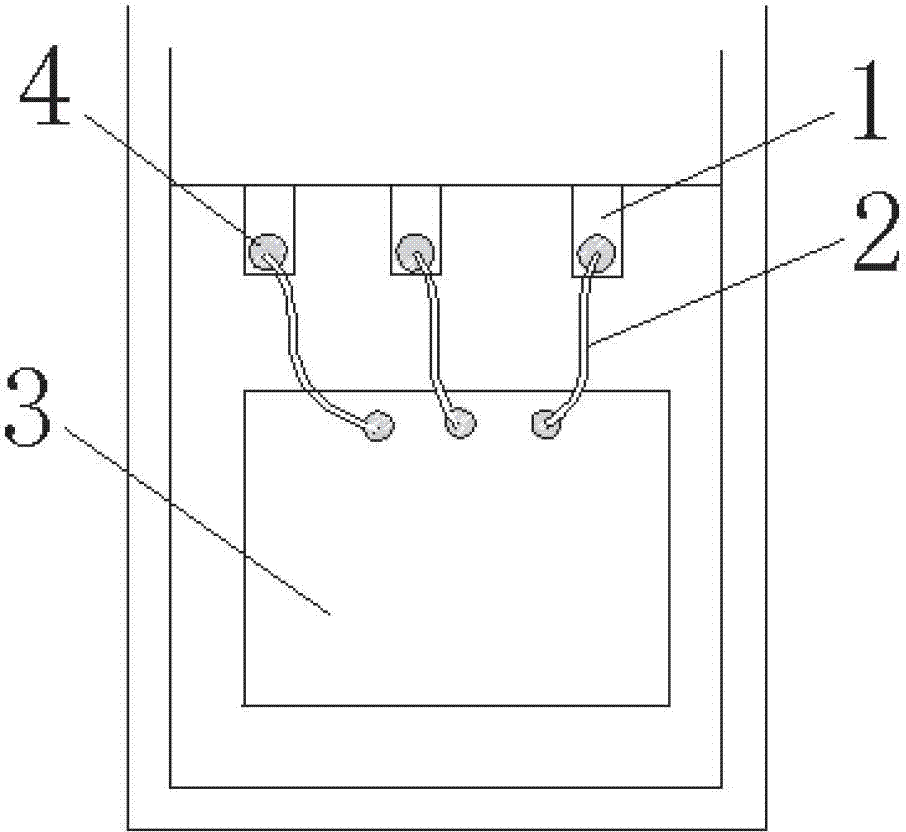

[0018] Such as figure 1 As shown, a plug-in connection structure between a circuit board and a housing, including a plug-in terminal 1 and a circuit board 3, both of which are provided with pads, and between the plug-in terminal 1 and the circuit board 3 through a binding wire 2. Bind and connect the pad 4 on the plug-in terminal to the pad on the circuit board.

[0019] Preferably, the pad is a gold-plated or silver-plated disk, which is less affected by temperature changes and has good connection stability. There is gel on the outside of the binding wire between the plug-in terminal and the circuit board to avoid the oxidation of the binding wire, which has the function of corrosion resistance and buffering external impact, and the connection is firm and stable.

[0020] In order to achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com