Eccentric grinding roller integrated efficient grinding machine

An eccentric, pulverizer technology, applied in grain processing and other directions, can solve problems such as the speed limit of the main engine, affecting the efficiency and output of the pulverizer, and achieve uniform workload, reduce maintenance time and cost, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

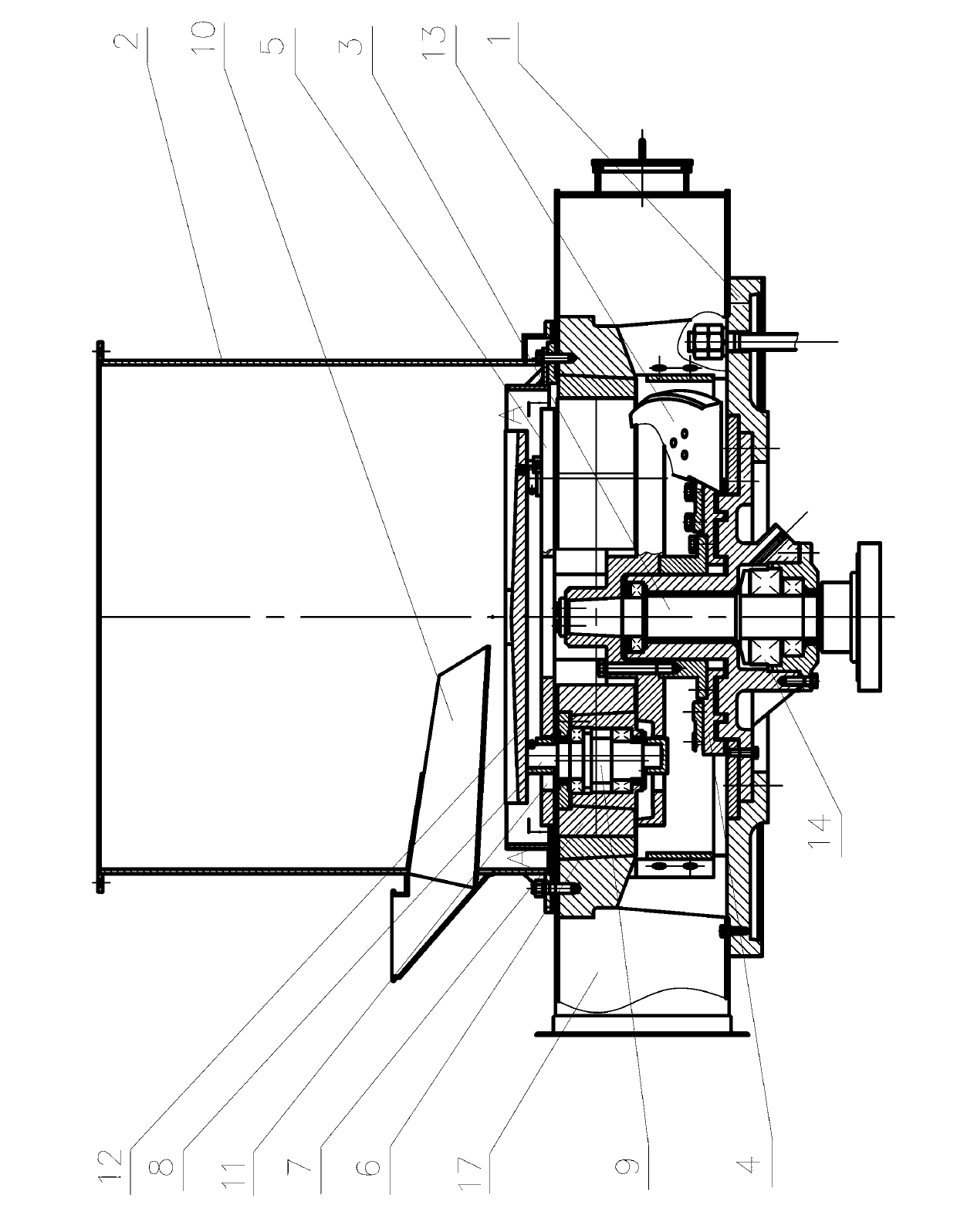

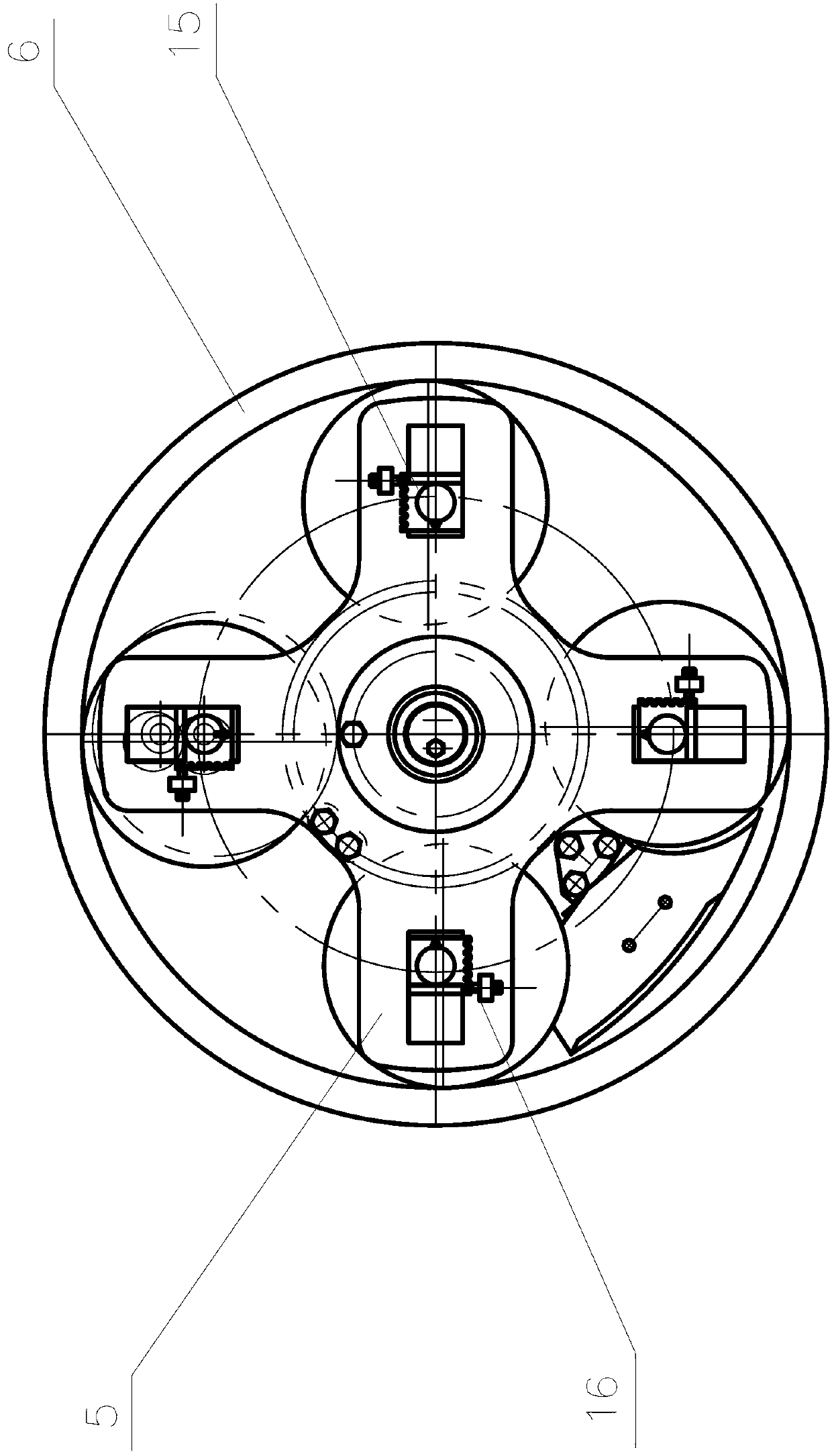

[0022] Below in conjunction with accompanying drawing, the technical scheme of invention is further described:

[0023] The eccentric grinding roller integrated high-efficiency grinding machine of the present invention, its grinding host is mainly composed of a base 1, a main shaft 3, a material throwing platform 4, a cover cylinder 2, a grinding roller frame 5, a grinding roller assembly, a grinding ring 6, and a material throwing device 13. Consists of a uniform material pan 12 and a feeding trough 10. The base 1 is fixed on the concrete machine base, the cover cylinder 2 is installed on the top of the base 1, and the air return box 17 is installed around the base 1, and the oblique feed trough 10 is arranged in the cover cylinder 2, and the classifier is provided with On the cover tube 2, the grinding ring 6 is coaxially installed on the inner ring wall of the upper opening of the base 1. The lower bearing position 14 of the main shaft at the center of the bottom of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com