Copper rod rolling mill

A copper rod and rolling mill technology, applied in metal rolling and other directions, can solve the problems of limited rolling capacity of a single rolling mill unit and difficulty in guaranteeing rolling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

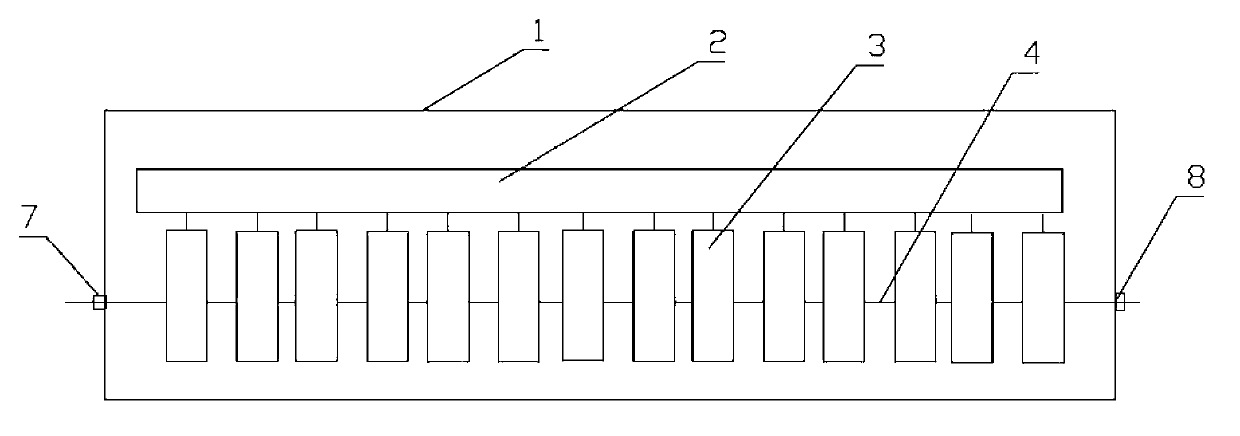

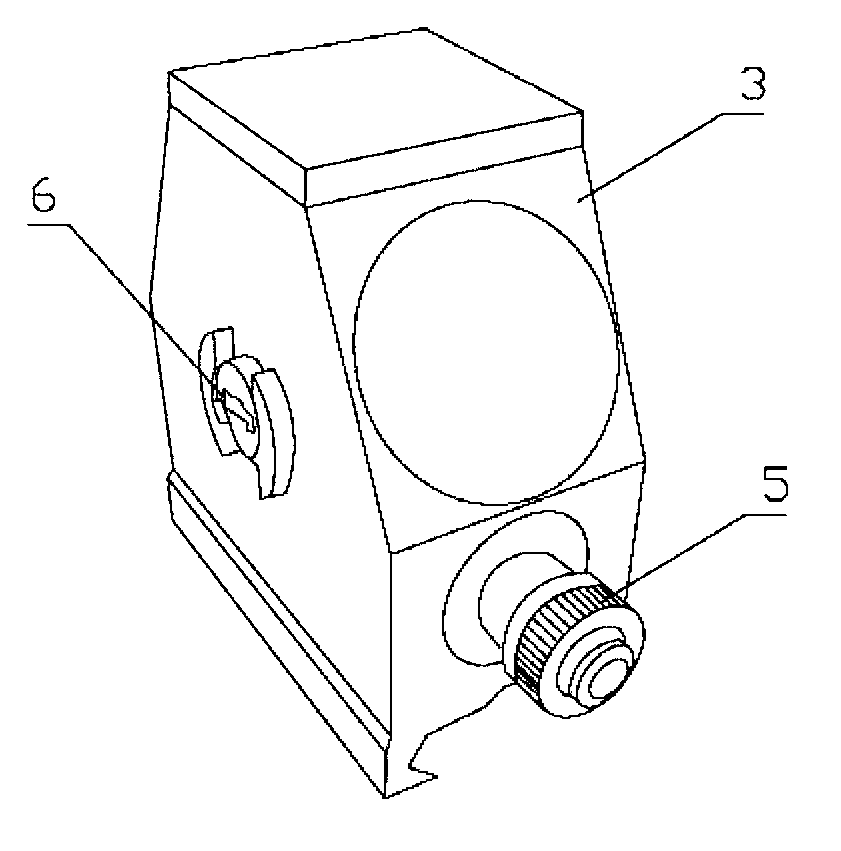

[0013] Such as figure 1 As shown, the copper rod rolling mill includes a housing 1, a gear box 2 and a rolling mill unit 3. The housing 1 is provided with a copper rod inlet 7 and a copper rod outlet 8. A row of 14 rolling mill units 3 is provided in the housing 1 along the copper rod. , the gears of each rolling mill unit 3 are respectively connected with the gear box in the casing. The structure of the rolling mill unit is as follows figure 2 As shown, the rolling mill unit 3 is provided with a copper rod inlet 6, a copper rod outlet and a gear 5, and the copper rod outlets of each adjacent rolling mill unit are set correspondingly to the copper rod inlets.

[0014] When the device is in use, the copper rod 4 is imported from the copper rod inlet 7, and the diameter of the copper rod 4 is gradually reduced under the rolling of different rolling mil...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap