Numerical control gear grinding machine

A gear grinding machine and cutter shaft technology, applied in automatic control devices, metal processing machinery parts, feeding devices, etc., can solve problems such as affecting the processing accuracy of products, destroying tracks, and lowering tracks, achieving compact structure, stable position adjustment, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, a specific embodiment is listed in conjunction with the drawings to further illustrate the present invention.

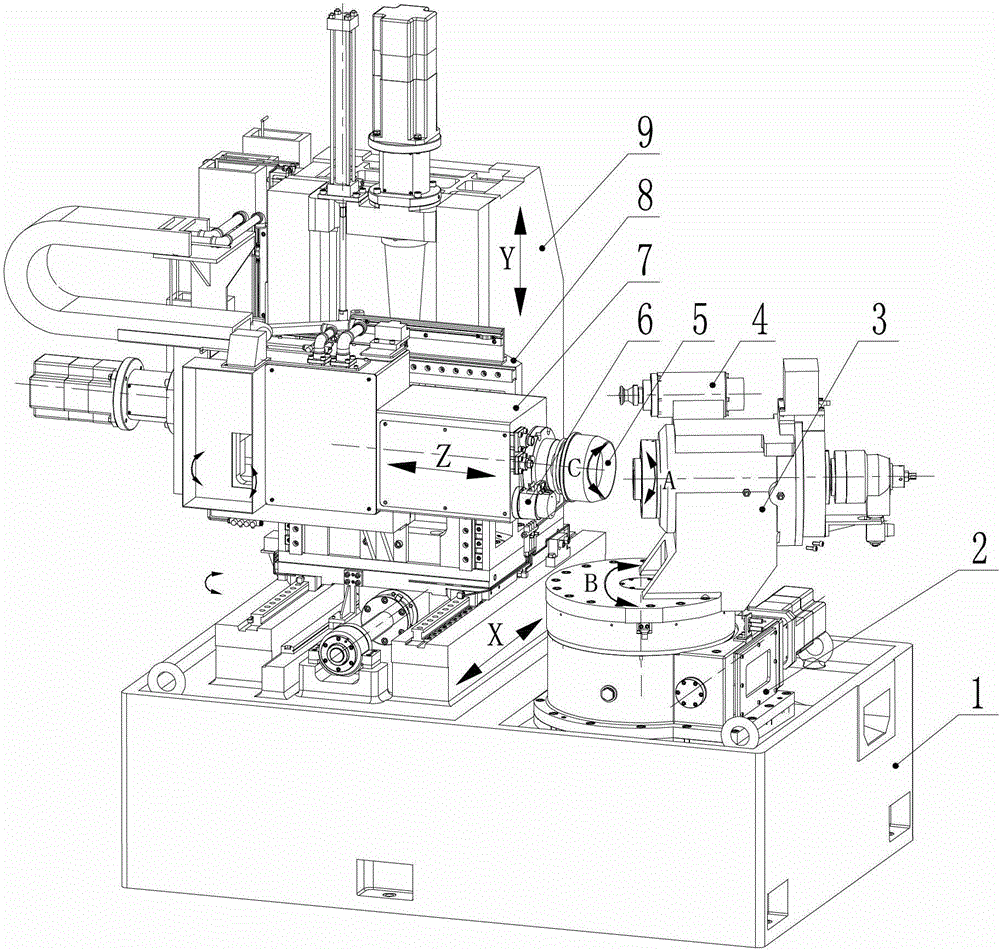

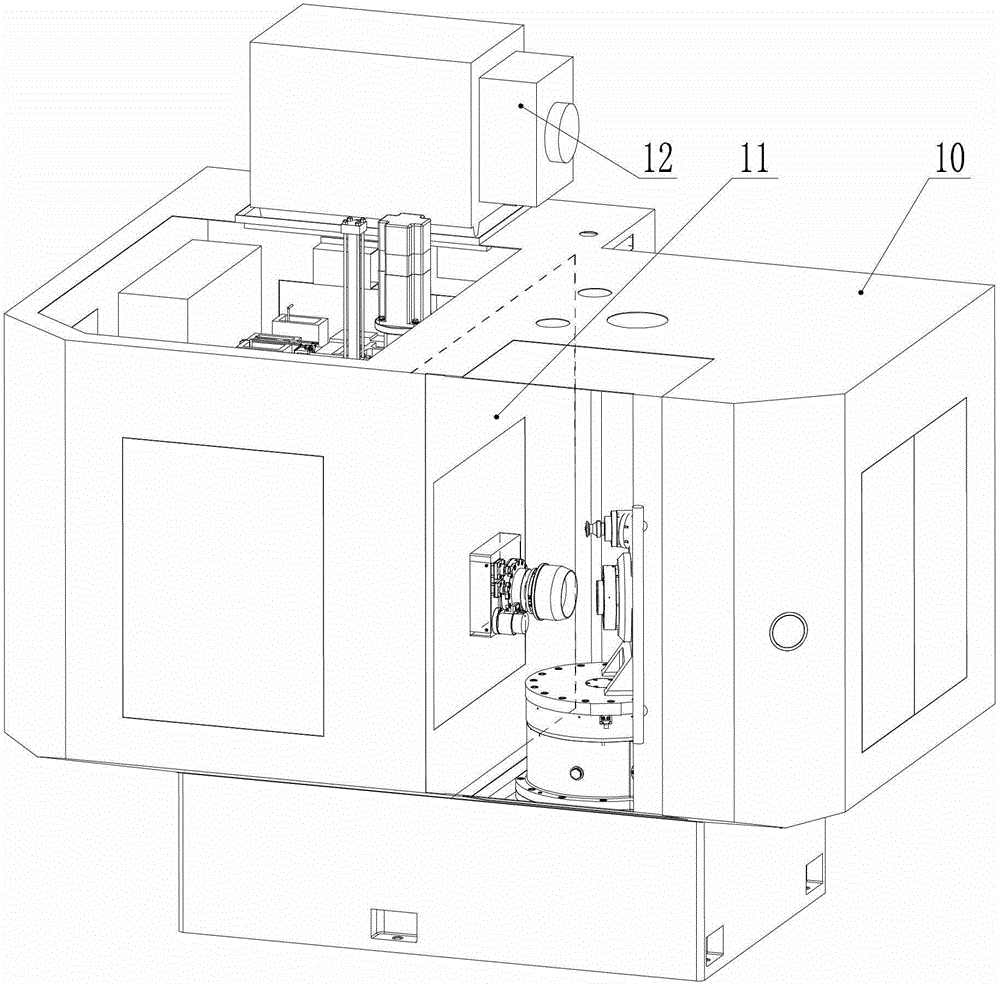

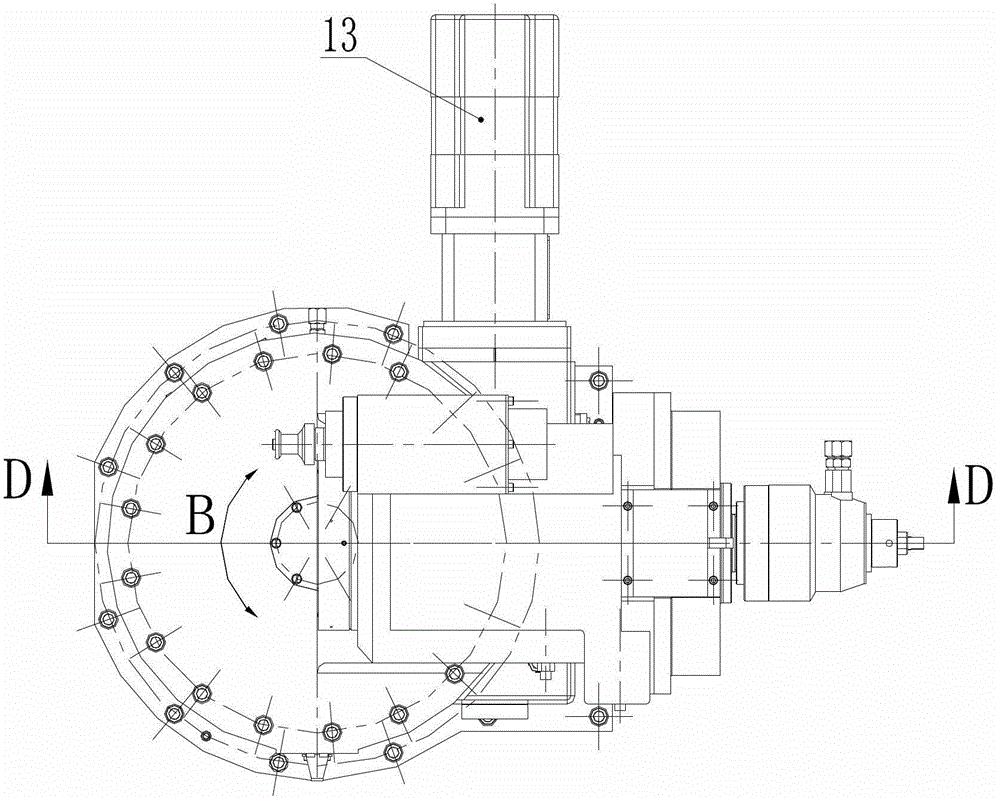

[0039] Such as figure 1 , figure 2 As shown, this embodiment is a numerical control gear grinding machine, which includes a bed, a tool shaft position adjustment device, and a workpiece spindle position adjustment device. The tool shaft position adjustment device and the workpiece spindle position adjustment device are both fixed on the bed.

[0040] The tool axis position adjustment device includes X-axis linear guide, column 9, Y-axis linear guide, tool box slide, Z-axis linear guide, tool box and tool axis; X-axis linear guide is fixed on the upper end surface of the bed, The column 9 is slidingly connected with the X-axis linear guide, the Y-axis linear guide is fixed on the side of the column, the cutter box slide 8 is slidingly connected with the Y-axis linear guide, and the Z-axis linear guide is fixed on the cutter box slide 8. The cutter shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com