Vacuum device for double-screw extruder

A twin-screw extruder and vacuum device technology, applied in the field of vacuum devices, can solve problems such as the quality decline of polyethylene separators, achieve the effects of low manufacturing cost, stable and continuous production, and avoid product quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

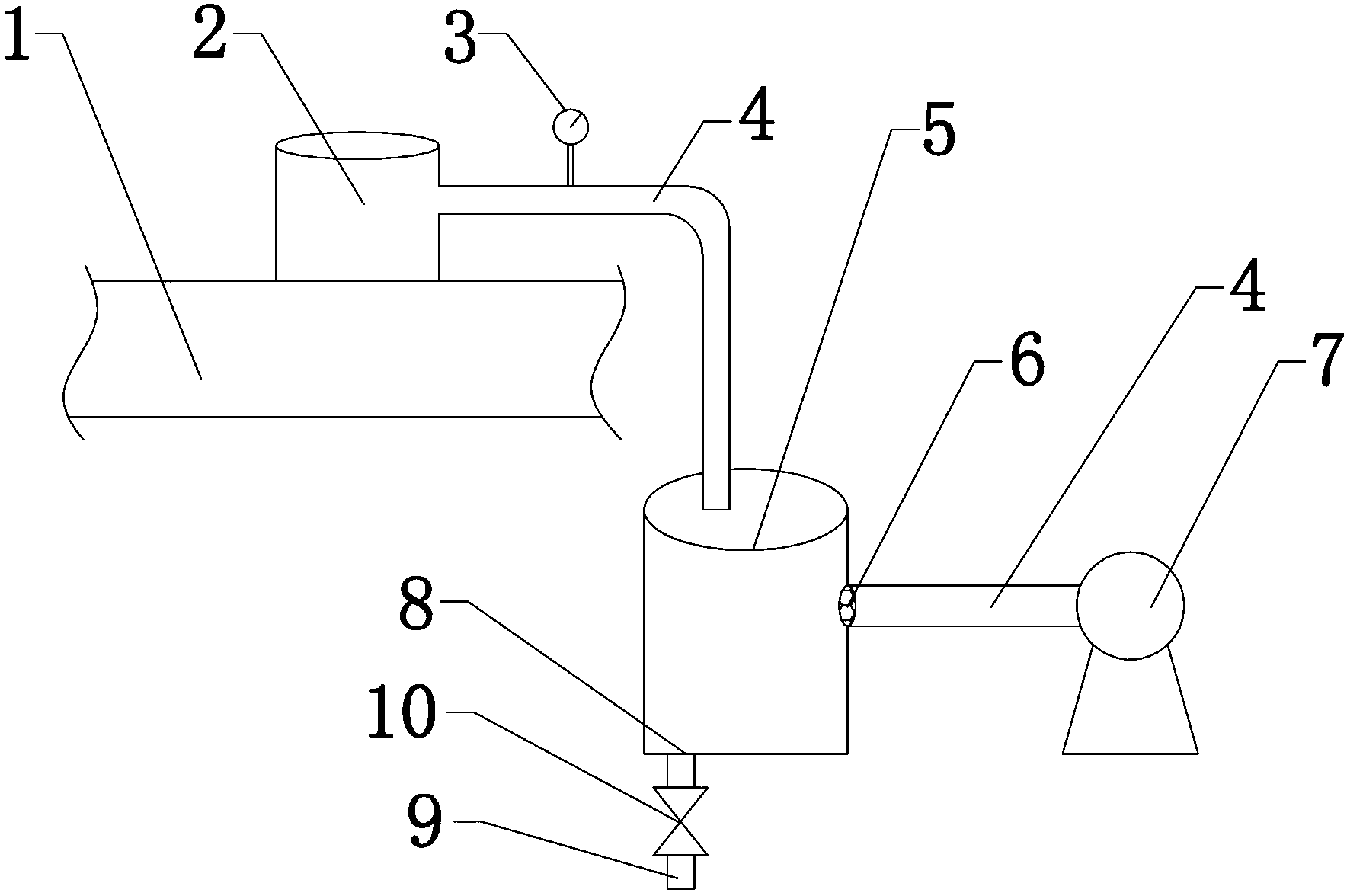

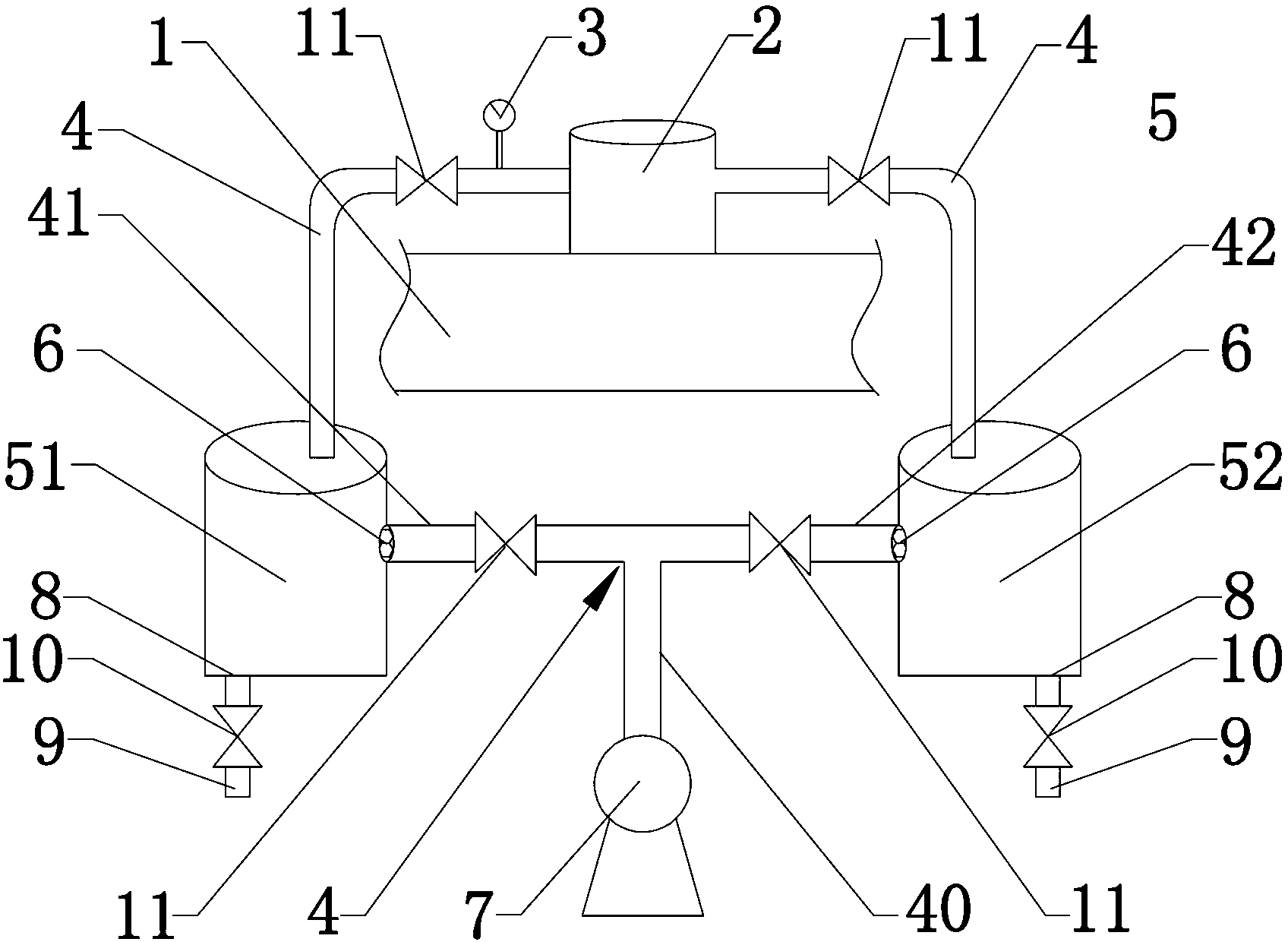

[0022] Such as figure 2 Shown: a vacuum device for a twin-screw extruder, including a twin-screw extruder 1, the twin-screw extruder 1 is provided with an exhaust port 2, and the exhaust port 2 passes through a vacuum pipe 4 and the first A buffer tank 51 is connected to the second buffer tank 52, and the first buffer tank 51 and the second buffer tank 52 are respectively connected to the vacuum pump 7 through the vacuum pipeline 4 provided outside them. The vacuum pipeline 4 is provided with a pipeline switching valve 11, wherein on the vacuum pipeline 4 between the first buffer tank 51 and the exhaust port 2, on the vacuum pipeline 4 between the second buffer tank 52 and the exhaust port 2, and on the vacuum pipeline 4 between the second buffer tank 52 and the exhaust port 2. Pipe switching valves 11 are provided on the vacuum pipeline 4 between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com