Damping device for exhaust pipe of automobile

A technology of vibration damping device and automobile exhaust, which is applied in the direction of power plant, gas intake of power plant, and vehicle parts, etc., can solve the problem of affecting the driving comfort of the whole vehicle, limited design space of exhaust pipe, and inability to design bellows. and other problems, to achieve the effect of good vibration reduction effect, small installation limitation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

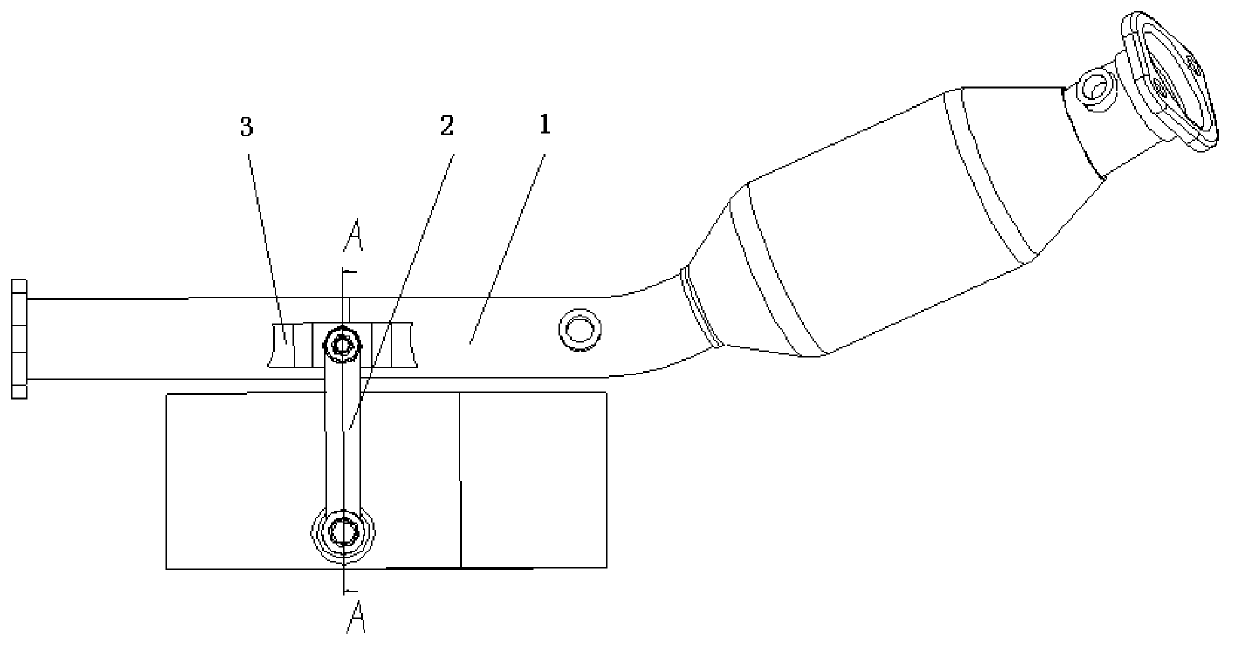

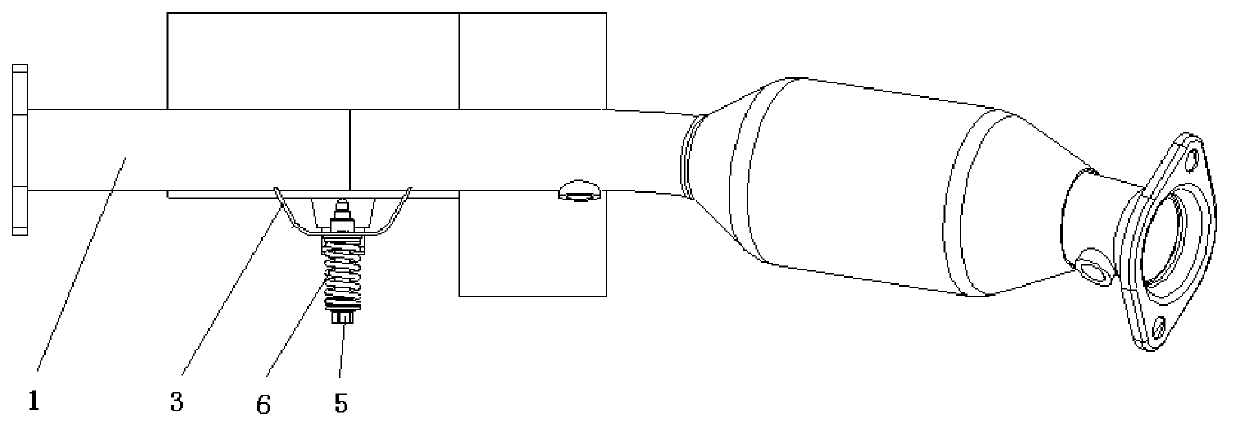

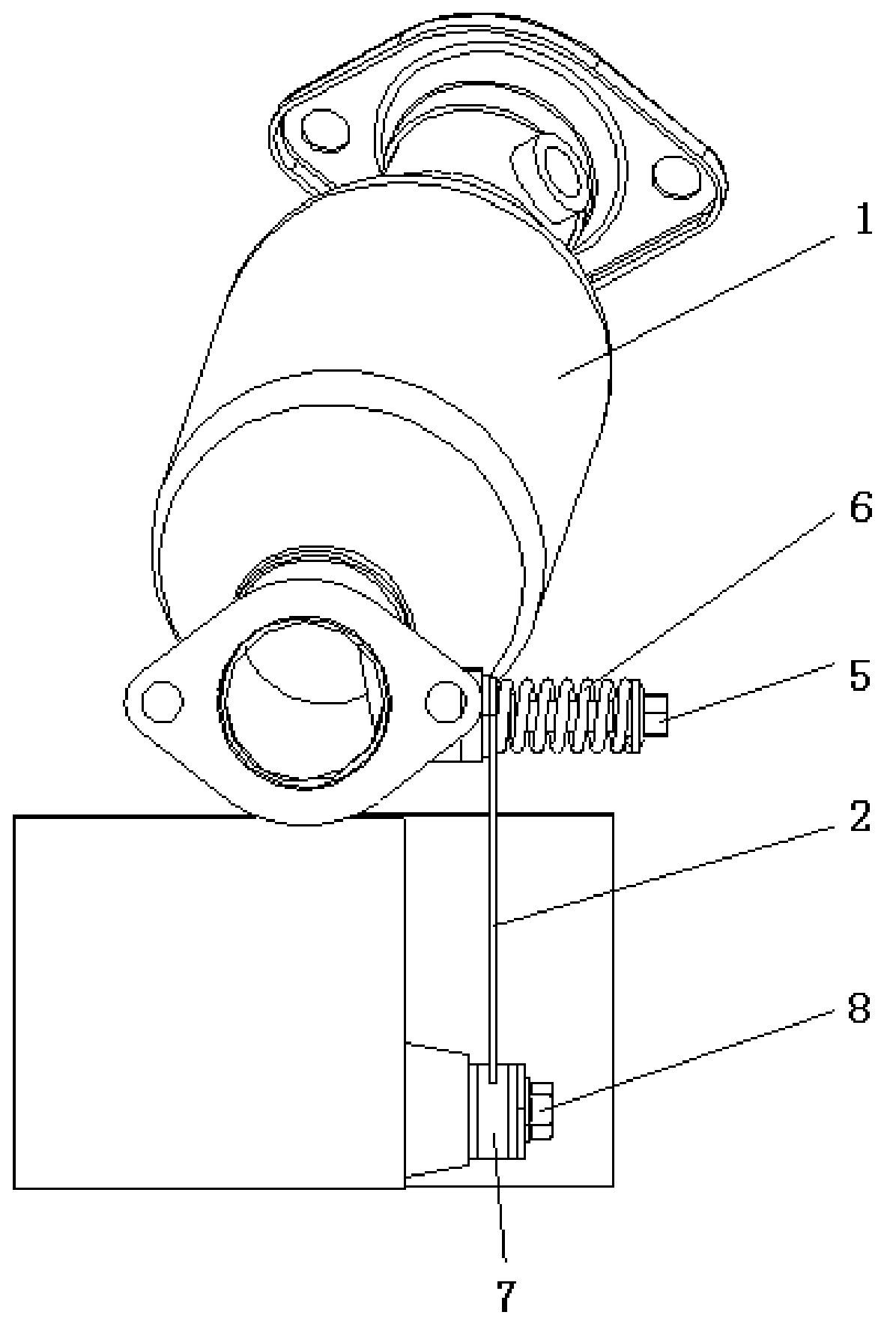

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides an automobile exhaust pipe damping device, which is installed between the exhaust pipe 1 of the automobile and the engine or transmission to attenuate engine vibration and improve driving comfort. Vibration devices include:

[0031] The shock absorber is fixedly arranged on the exhaust pipe 1 .

[0032] The connection part 2, the first end of the connection part 2 is fixedly connected with the shock absorber, and the second end of the connection part 2 is fixedly connected with the engine or the transmission.

[0033] A damping component made of damping material is also provided at the connection between the second end of the connecting component 2 and the engine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com