Toughened glass unit and manufacturing method and cover plate having toughened glass unit

A technology for strengthening glass and manufacturing methods, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve problems such as product fragmentation, glass strength drop, and strengthened glass yield drop, so as to reduce manufacturing costs and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

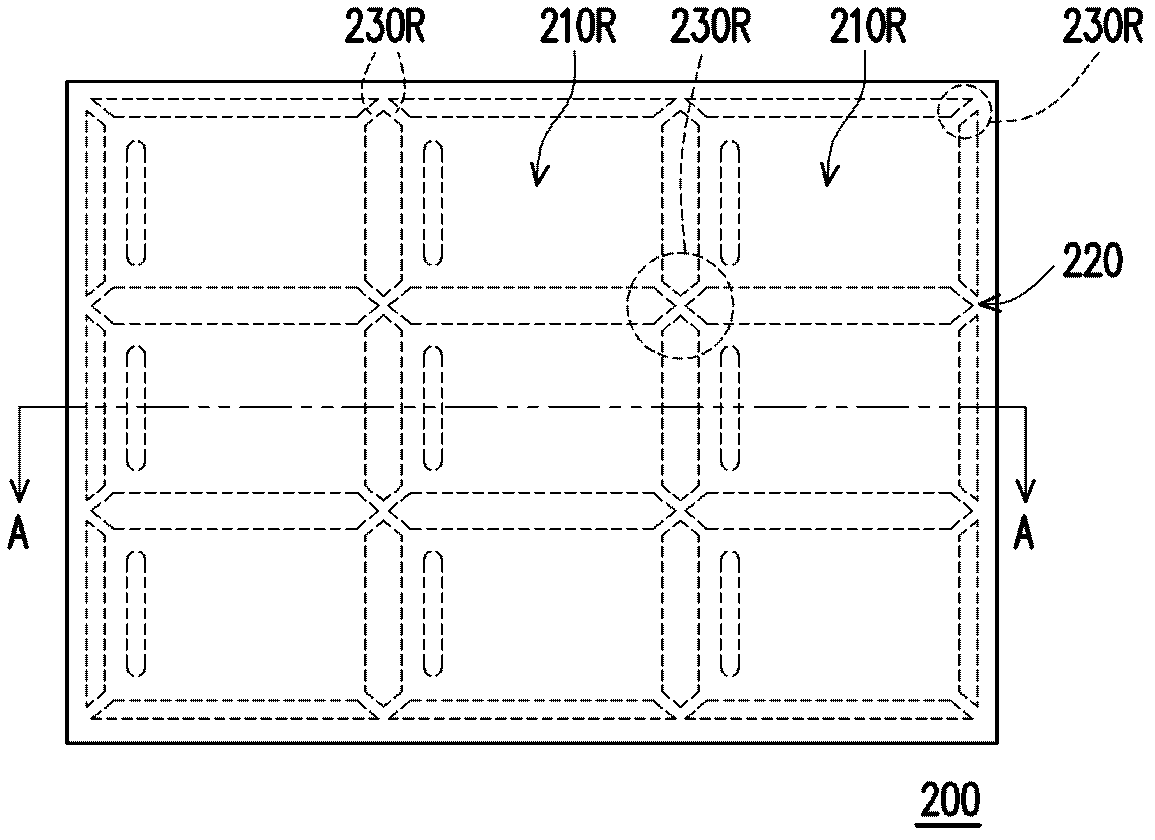

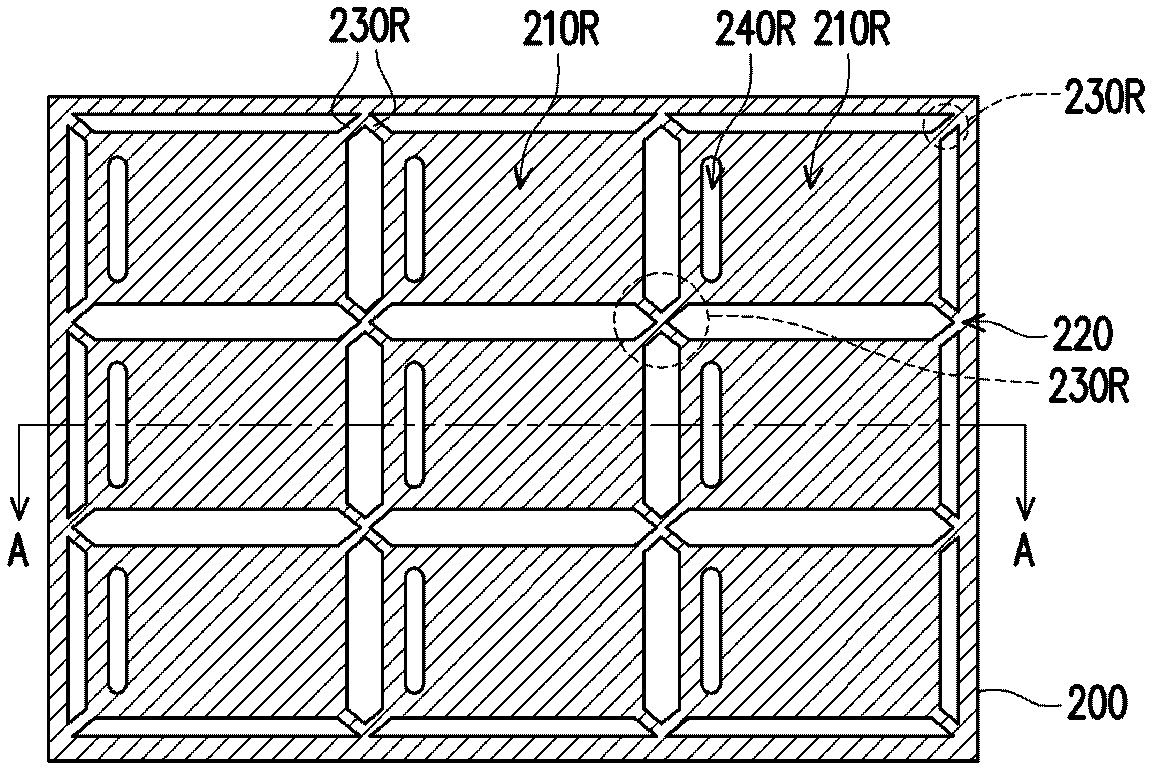

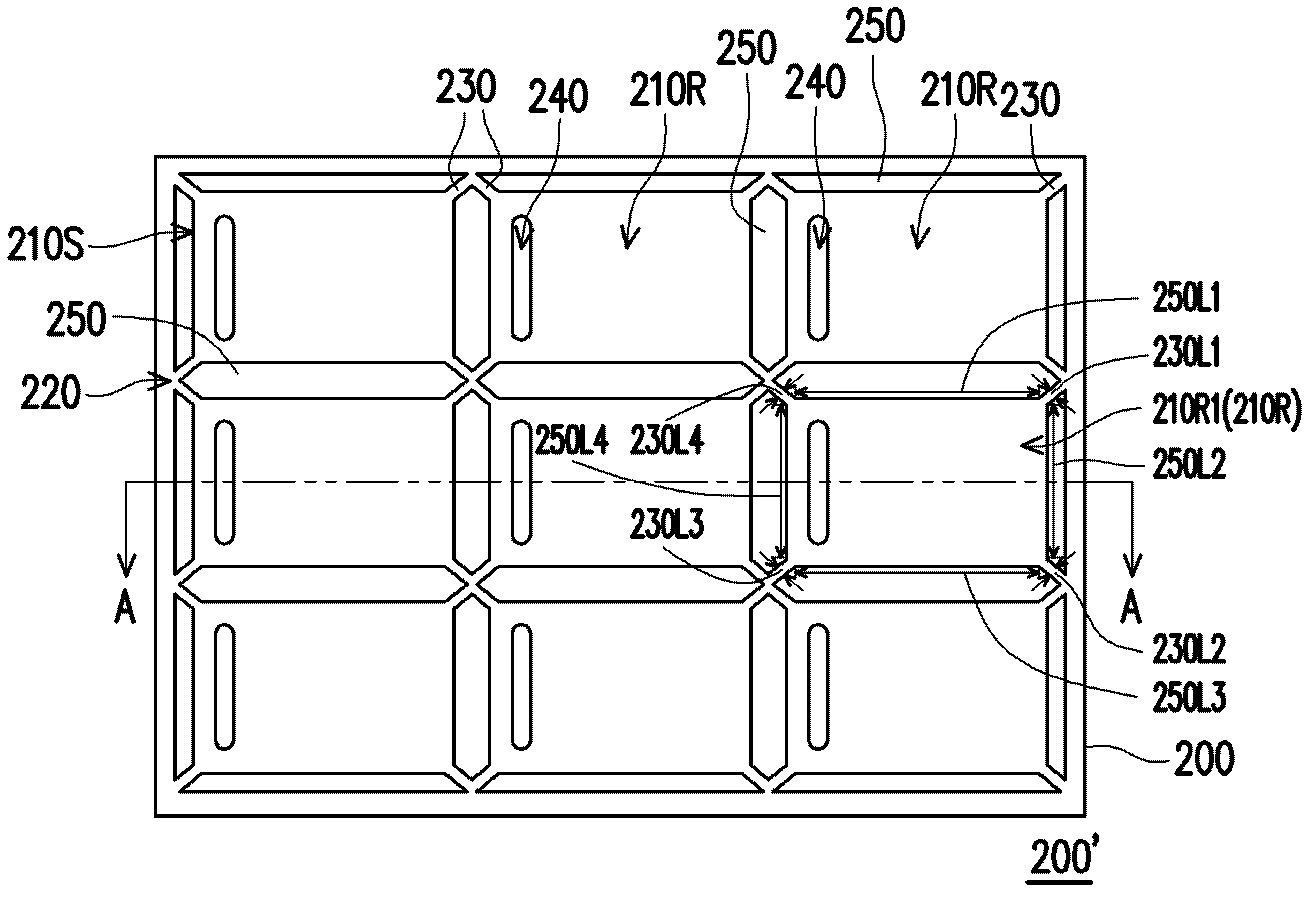

[0051] Figure 1A to Figure 1F It is a schematic top view of the manufacturing process of the strengthened glass unit according to an embodiment of the present invention, and Figure 2A to Figure 2F corresponding to Figure 1A to Figure 1F Schematic cross-sectional view of the fabrication process of the strengthened glass unit along section line AA in . Please refer to Figure 1A and Figure 2A Firstly, a glass base material 200 is provided, and the glass base material 200 has a plurality of glass unit predetermined regions 210R. In this embodiment, nine glass unit predetermined areas 210R in a 3×3 matrix are planned on the glass base material 200, but the present invention is not limited thereto. The size of the glass unit predetermined areas 210R on the glass base material 200 Appropriate adjustments can be made based on the configuration of the effective area on the glass base material 200 , the process window on the production line, and the product requirements. In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com