Device for extracting plant essential oil

A technology for extracting device and plant essential oil, applied in the directions of essential oil/spice, fat production, etc., can solve the problems of wasting water, rough separator, poor cooling effect, etc., to reduce the stop flow time and process, shorten the pipeline connection The effect of reducing the distance and shortening the feeding and discharging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

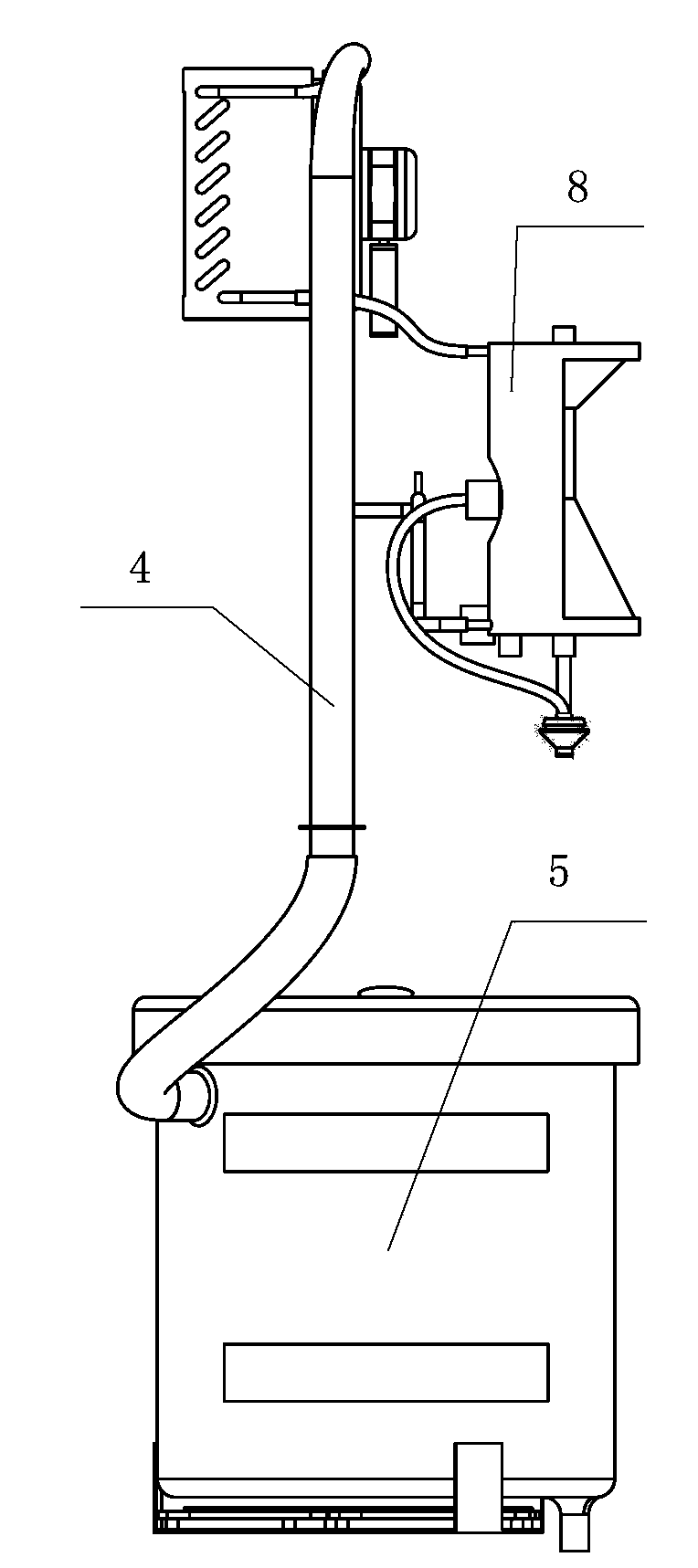

[0031] See attached Figure 1-6 , the present invention integrates three functions of distillation, cooling and separation, which includes an electric distillation pot located at the lower part for heating, a steam condenser 1 located at the middle and an oil-water separator 8 located between the two;

[0032] See attached Figure 15 , the shape of the oil-water separator 8 is a cylinder, which includes three connected spaces. The spaces are the conical essential oil collector 8-1 at the top, the inverted cone-shaped pure dew collector 8-3 at the bottom, and the essential oil collector 8-1 and the pure dew collector 8-1. The columnar essential oil collection display neck 8-2 between 3, the upper part of the essential oil collector 8-1 is provided with an air release port 8-4, which can prevent disturbance, and the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com