Manufacturing method of ceramide production promoter

A technology of ceramides, manufacturing methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, preparations for skin care, etc., to achieve the effect of improving moisturizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

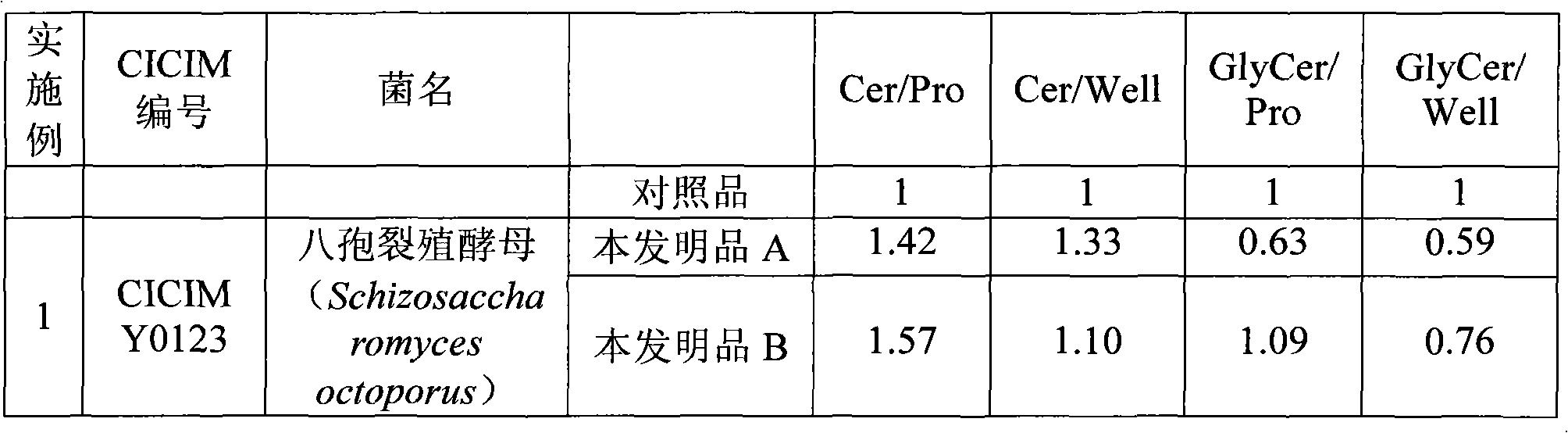

Embodiment 1

[0044]

[0045] First, the culture medium is prepared according to the following method: Soak soybeans in water for 12 hours to allow the soybeans to fully absorb water, then grind and crush the absorbed soybeans, filter them to remove liquid components, and drain the remaining residues to obtain bean dregs. The okara was mixed with glucose and water, and the concentrations of the okara and glucose in the mixture were respectively 10w / v% and 1w / v%, and the mixture was used as a culture medium.

[0046] Then, add 100 ml of the above-mentioned culture medium to the Erlenmeyer flask, inoculate a certain amount of Schizosaccharomyces octoporus (preserved in CICIM, Industrial Microbiology Resource and Information Center, Jiangnan University, No. CICIM Y0123), and cultivate at 30°C 3 days.

[0047] The resulting culture was then centrifuged (3000 rpm, 10 minutes). The remaining supernatant was diluted with 2.5 times of absolute ethanol, and the mixture diluted with absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com