Wood fiber used for towels

A wood fiber and towel technology, applied in the field of wood fiber, can solve the problems of poor touch, hard texture, hard contact, etc., and achieve the effects of ensuring body safety, strong resistance to loss, and high penetration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

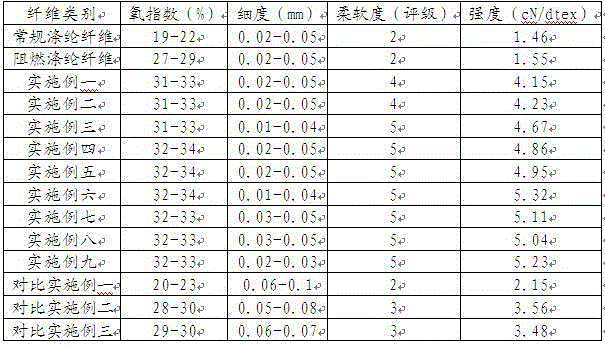

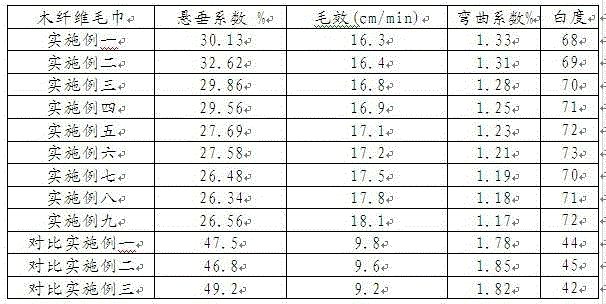

Examples

Embodiment 1

[0029] Select natural and pollution-free three-year-old pine trees, crush them, and then soak them in the cooking wood pulp, the weight ratio of wood and cooking wood pulp is 100:8, and the cooking wood pulp is 100 parts by weight of water, 15 parts of milk mother soap, and 8 parts of mineral oil Mixed with 5 parts of emulsifier OP;

[0030] Then put the crushed wood soaked in the cooking wood pulp into the microwave vacuum tank, evacuate until the vacuum degree is -0.02MPa, and then carry out the microwave cooking wood pulp treatment, the microwave frequency is 300MHz, and the microwave treatment time is 10min;

[0031] Extract wood fiber from wood pulp after cooking wood pulp; then bleach and impregnate flame retardant treatment,

[0032] Impregnated flame retardant treatment adopts vacuum pressure flame retardant treatment: in the process of treatment, first put the wood filament fiber obtained after bleaching into a vacuum pressurized tank to evacuate to make the vacuum de...

Embodiment 2

[0037] Select Australian biennial eucalyptus, soak in the cooking wood pulp, the weight ratio of wood and the cooking wood pulp is 100:2, and the cooking wood pulp is 100 parts by weight of water, 20 parts of milk soap, 10 parts of mineral oil and 8 parts of plain Add O emulsifier and mix;

[0038] Then put the pulverized wood soaked in the cooking wood pulp into the microwave vacuum tank, evacuate until the vacuum degree is -0.001MPa, and then carry out the microwave cooking wood pulp treatment, the microwave frequency is 950MHz, and the microwave treatment time is 20min;

[0039] Extract wood fiber from wood pulp after cooking wood pulp; then bleach and impregnate flame retardant treatment,

[0040] Impregnated flame retardant treatment adopts vacuum pressure flame retardant treatment: in the process of treatment, first put the wood filament fiber obtained after bleaching into a vacuum pressurized tank to evacuate to make the vacuum degree -0.025Mpa, and then add the flame r...

Embodiment 3

[0044] Select natural raw and pollution-free three-year-old pine wood, soak in the cooking wood pulp, the weight ratio of wood and the cooking wood pulp is 100:5, and the cooking wood pulp is 100 parts by weight of water, 18 parts of milk soap, 9 parts of mineral oil and Mix 6 parts of emulsifier OP;

[0045] Then put the pulverized wood soaked in the cooking wood pulp into a microwave vacuum tank, evacuate until the vacuum degree is -0.01MPa, and then carry out microwave cooking wood pulp treatment, the microwave frequency is 600MHz, and the microwave treatment time is 15min;

[0046] Extract wood fiber from wood pulp after cooking wood pulp; then bleach and impregnate flame retardant treatment,

[0047] Impregnated flame retardant treatment adopts vacuum pressure flame retardant treatment: in the process of treatment, first put the wood filament fiber obtained after bleaching into a vacuum pressurized tank to evacuate to make the vacuum degree -0.02Mpa, and then add the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com