Triangular caisson

A triangular, caisson technology, applied in caisson, hydraulic engineering, marine engineering and other directions, can solve the problems of inability to use, large base pressure, large amount of reinforced concrete and backfill, etc., to achieve overall stability improvement, uniform base pressure, resistance to Good sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

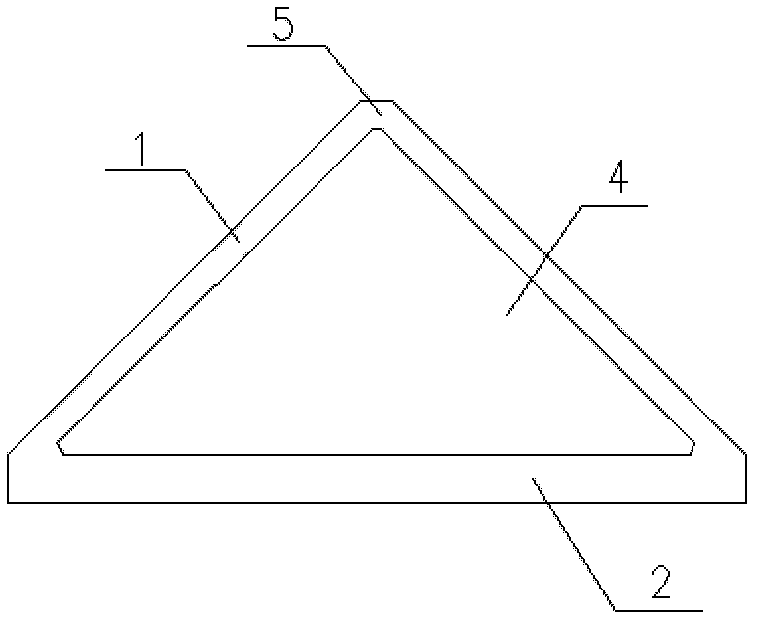

[0035] Example 1: Typical triangular caisson

[0036] The length of a dike is 1km, the beach elevation along the line is -4.5m, the design low water level is -1.5m, the average water level is 0.8m, and the wave H 1% = 3m, the elevation of the dike crest is 1m, and the minimum thickness of the riprap foundation bed 7 is 0.5m.

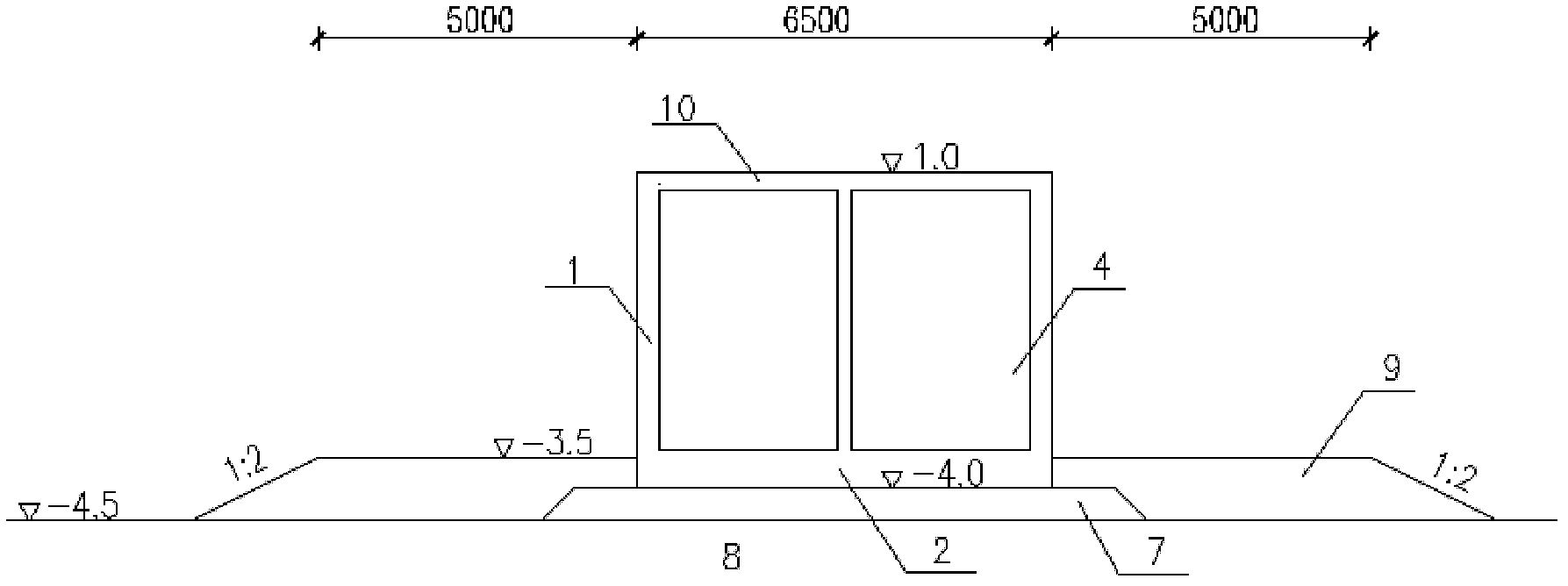

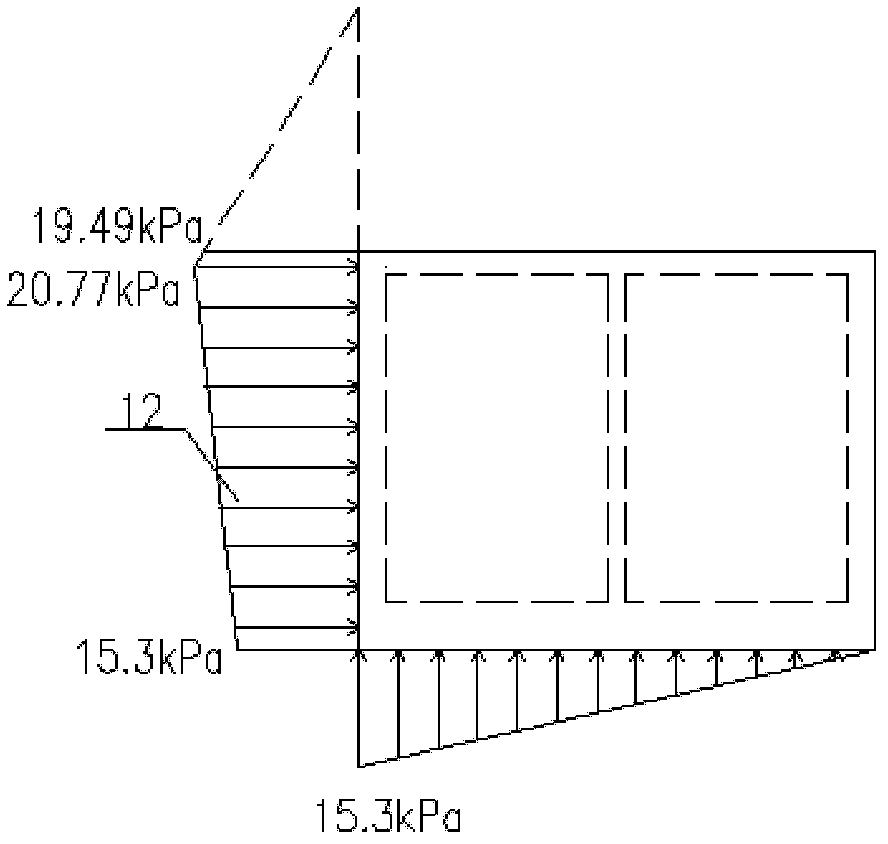

[0037] When using prior art rectangular caissons, see figure 1 , figure 2 , the length of a single piece is 4m, the elevation of the dike crest is 1m, the width of the dike crest is 7m, the thickness of the riprap foundation bed 7 is 0.5m, the thickness of the side plate 1 is 0.35m, the thickness of the bottom plate 2 is 0.6m, the thickness of the sealing plate 3 at both ends is 0.2m, and the thickness of the middle back The filler 4 is fine sand, backfilled to the bottom of the roof, and the thickness of the roof 10 is 0.35m. The amount of concrete for a single piece is 45m 3 , the engineering volume of the riprap foundation bed 7 and the shoulder ...

Embodiment 2

[0039] Embodiment 2: Triangular caisson with rectangular baffles

[0040] see Figure 8 , Figure 9 , the top of the triangular caisson is provided with a baffle plate 6 with a rectangular horizontal section, and the rest are the same as in Embodiment 1.

Embodiment 3

[0041] Embodiment 3: Triangular caisson with wavy baffles

[0042] see Figure 10 , The top of the triangular caisson is provided with a baffle plate 6 with a wave-shaped horizontal section, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com