External reinforcing ring type square steel post special-shaped node with different beam heights

A technology of external reinforcement rings and special-shaped nodes, which is applied in the direction of architecture and building structure, can solve the problems of unbalanced strength, difficult construction, complex structure, etc., and achieve the goals of improving production efficiency, shortening construction period, good ductility and seismic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

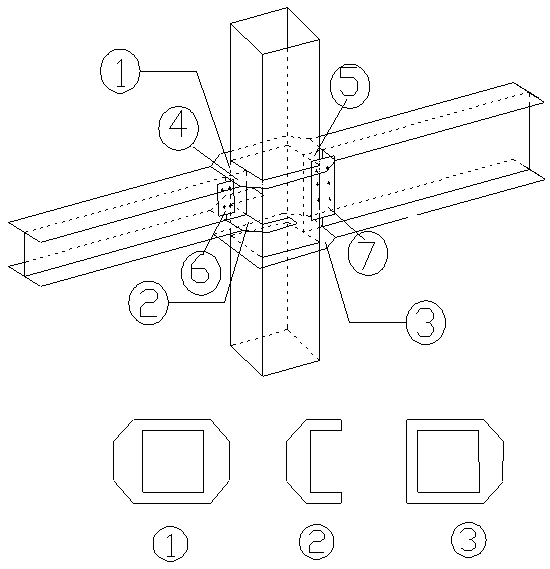

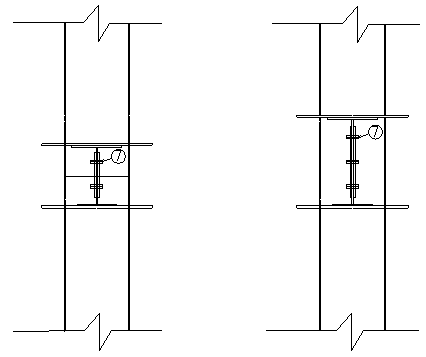

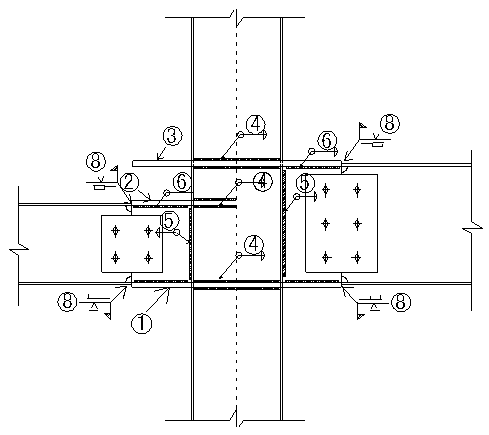

[0015] The special-shaped joints of the externally reinforced ring-type square steel columns with different beam heights proposed by the present invention are as follows: Figure 1~Figure 3 shown.

[0016] The special-shaped joints of externally reinforced ring-type steel structures with different beam heights are mainly composed of square steel columns, externally reinforced ring plates, connecting webs, H-shaped steel beams, and bolts.

[0017] The manufacturing method of special-shaped joints of externally reinforced ring-type square steel columns with different beam heights, ① on the square steel column according to the size of the steel beam, weld three externally reinforced ring plates on the column with fillet welds, ② according to the specific size of the steel beam Use fillet welds to weld the connecting web to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com