Bidirectional material impacting method and bidirectional material impacting device

A material and impact rod technology, which is applied to driving devices, earth-moving drilling, cutting machinery, etc., can solve the problems of reducing the service life of impact mining devices, consuming a lot of manpower, material resources and time, and difficult to solve the problem of turning the fuselage. Save mining time, improve device life, and ensure the effect of vertical impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

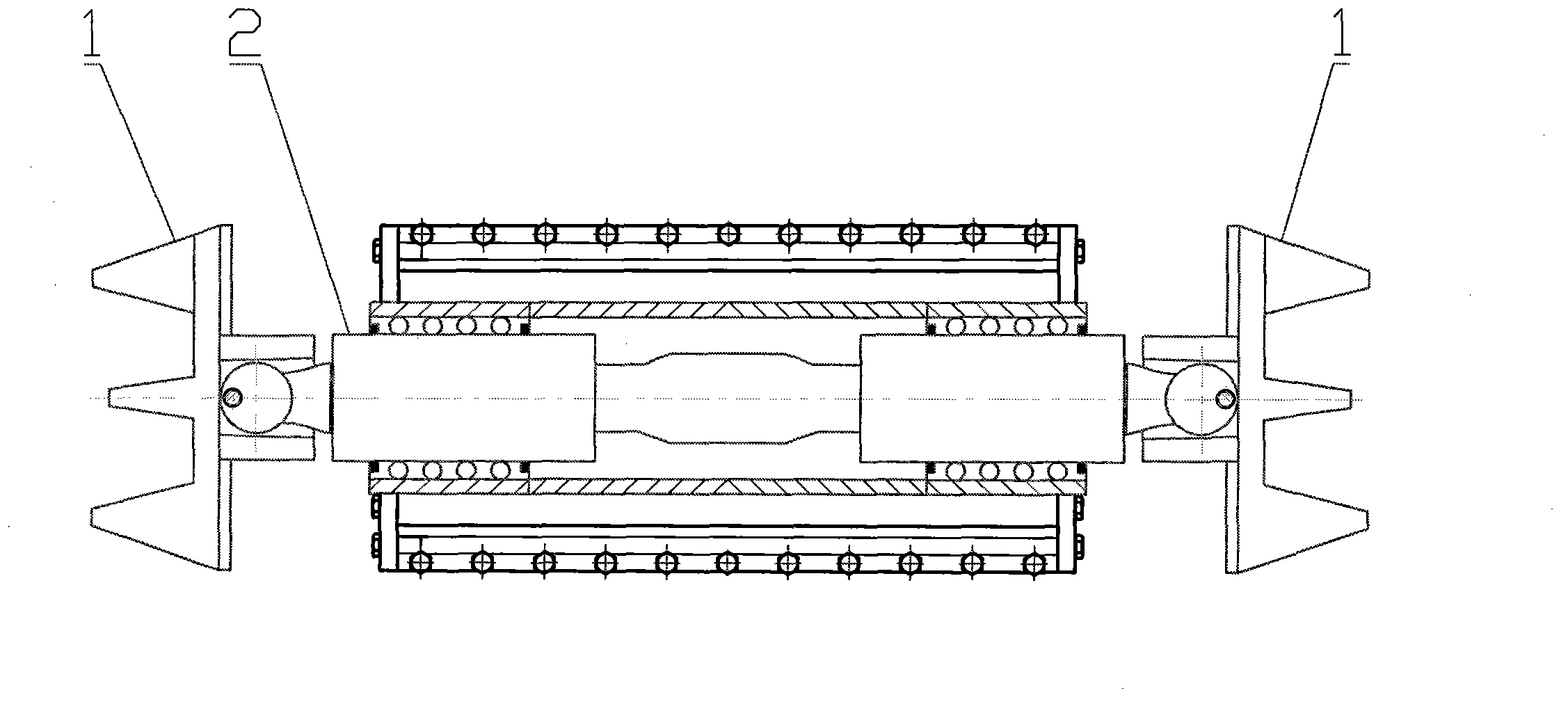

[0063] Figure 1 to Figure 2 It is the two-way impact material device described in Example 1. The two-way impact material device includes an impact rod 2, an impact head 1, and an impact drive mechanism 3. The impact head 1 is arranged at both ends of the impact rod 2. The impact drive mechanism 3 drives the impact rod 2 to reciprocate, and the impact rod 2 drives the impact head 1. Reciprocating impact for mining and falling materials. The impact head 1 and the impact rod 2 are fixed in a separate connection.

[0064] The impact head 1 and the impact rod 2 can also be of an integral structure.

[0065] When it is necessary to frequently adjust the position of the material to be mined, the impact head 1 can be rotated or moved up and down relative to the impact rod 2 .

[0066] In order to improve the use environment of the parts of the two-way impact material device, a lubrication system can be installed on the impact rod 2 or the driving mechanism, and the operation mode ...

Embodiment 2

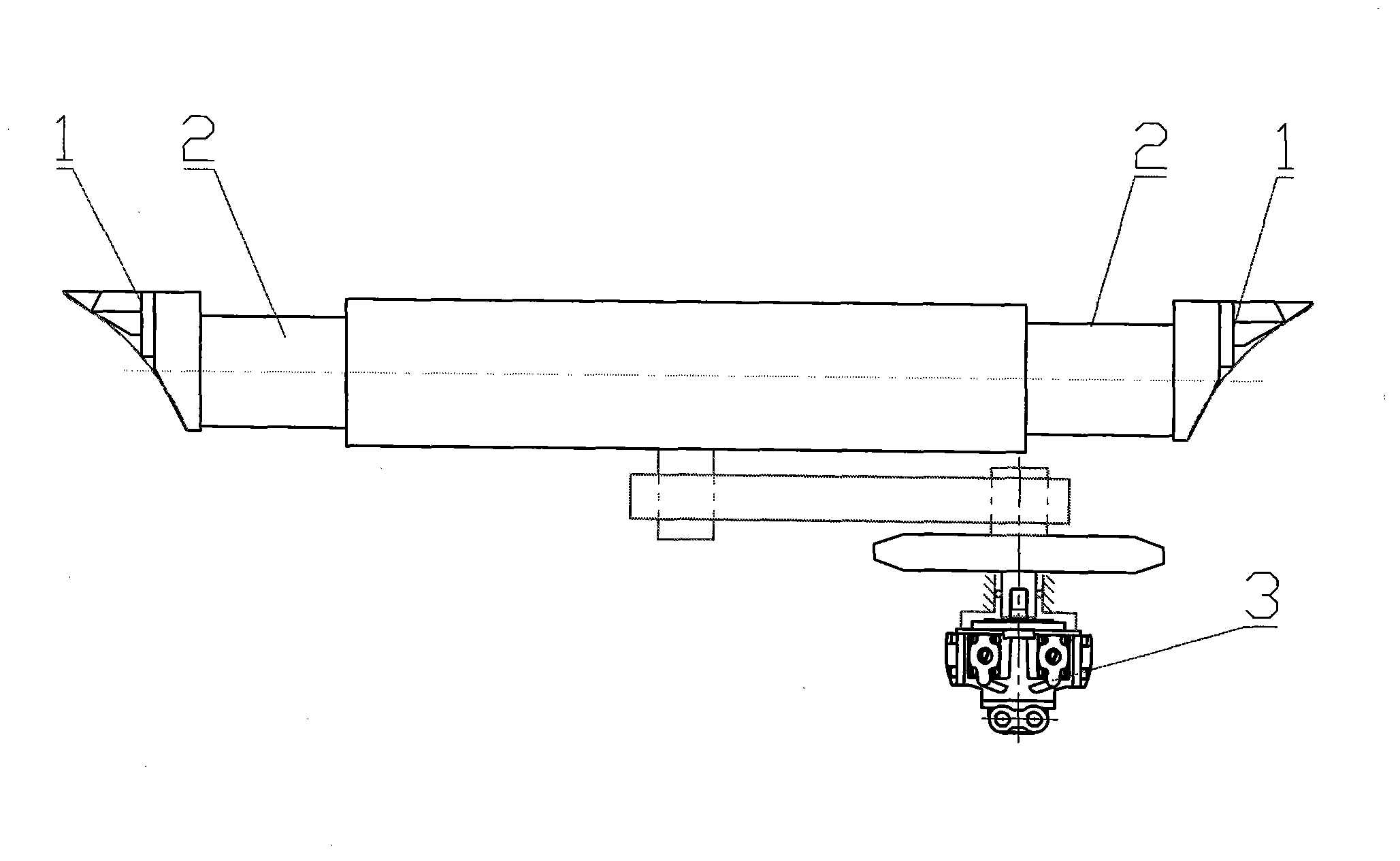

[0071] image 3 It is the two-way impacting material device described in Embodiment 2, which is different from Embodiment 1 in that: each end of the impact rod 2 is provided with two impact heads 1, and the impact rod 2 drives the impact heads 1 at both ends to reciprocate. The impact head 1 at the front of the impact bar 2 impacts blanking when the impact material device moves forward, and the impact head 1 at the rear of the impact bar 2 impacts blanking when the impact material device moves backward.

[0072] One or more than two impact heads 1 may also be provided at both ends of the impact rod 2 .

[0073] Others are with embodiment 1.

Embodiment 3

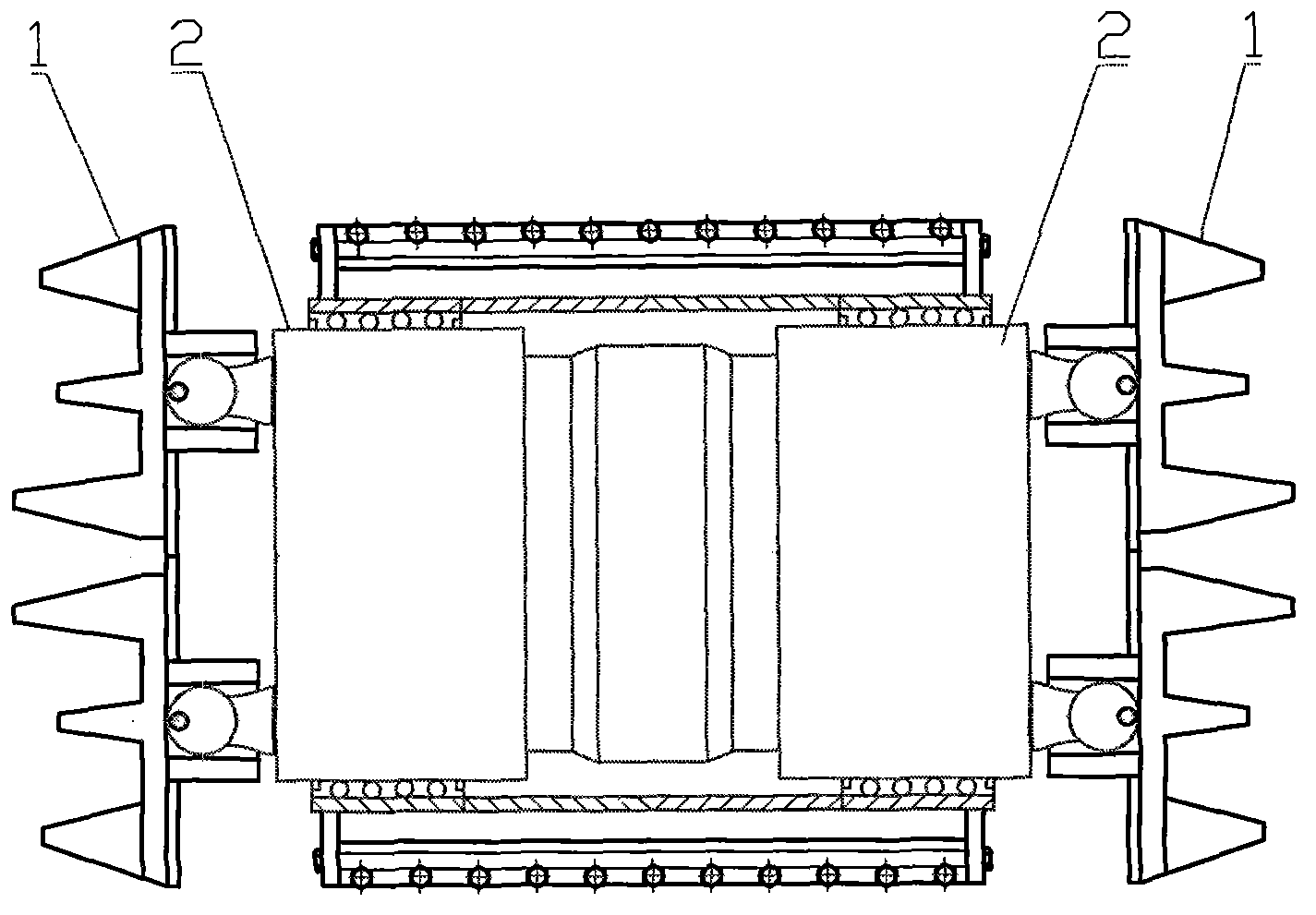

[0075] Figure 4 with Figure 5 It is the two-way impact material device described in Embodiment 3, which is different from Embodiment 1 in that: the impact heads 1 at both ends of the impact rod 2 are symmetrically arranged at both ends of the impact rod 2 .

[0076] The impact head 1 can also be a plurality of impact heads 1 , and the plurality of impact heads 1 can be arranged at two ends of different impact rods 2 .

[0077] The impact head 1 can also be arranged asymmetrically on both ends of the impact rod 2 .

[0078] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com