Solar panel roof installation structure and installation method thereof

A technology for solar panels and installation structures, applied in the field of solar energy applications, can solve problems such as potential safety hazards, affecting the life of buildings, and increasing the fatigue strength of solar collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

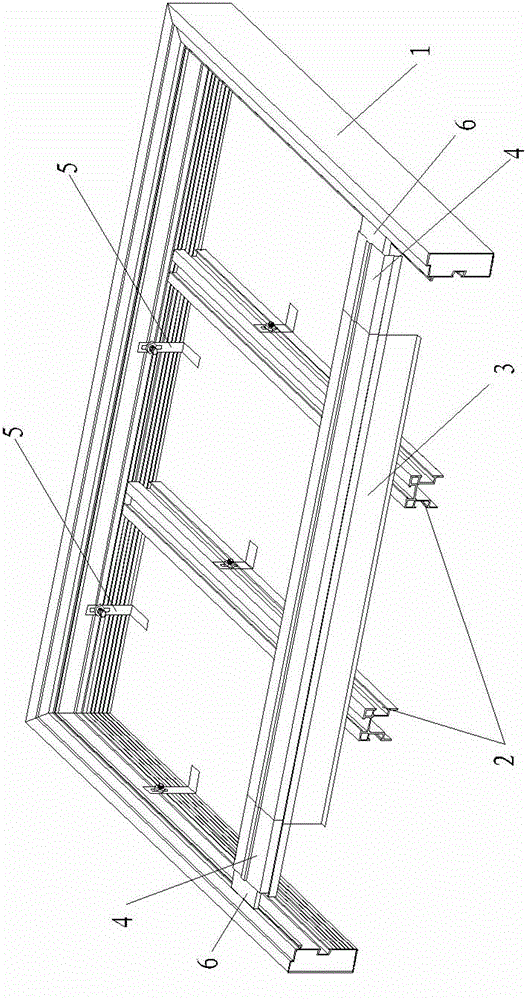

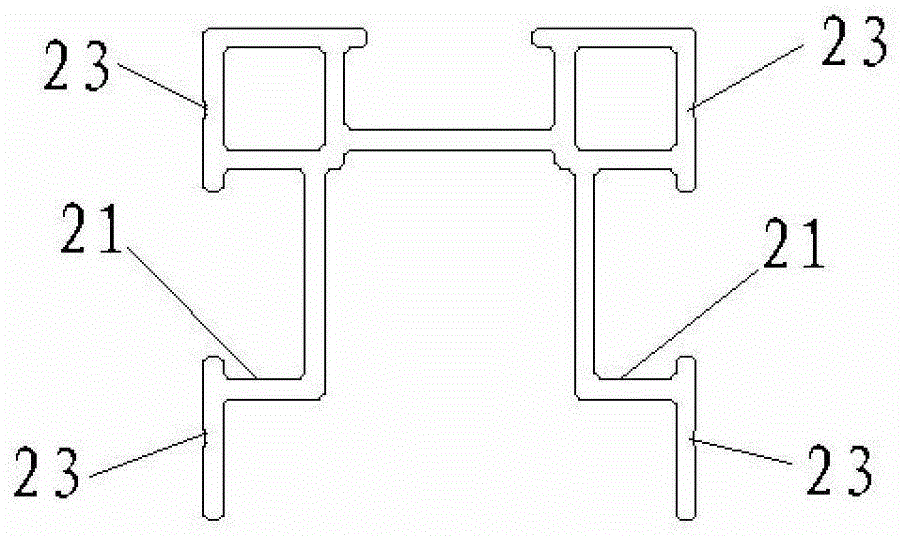

[0027] see figure 1 As shown, the roof installation structure of the solar panel of the present invention mainly includes a frame 1, a longitudinal keel 2, a transverse keel 3, a connecting piece 5 and a glass cover plate.

[0028] Wherein, the connector 5 of the present invention is an L-shaped 90-degree steel part, and its horizontal plane is fixed with the roof embedded parts by means of welding, etc., and a screw hole is opened on the vertical plane for fixing the frame 1 and the longitudinal keel 2 on the roof superior. Preferably, the screw hole of the connecting piece 5 is an elongated hole, which is about 20-50 mm long in the vertical direction, so that the frame 1, the longitudinal keel 2 and the The pitch of the roof, so as to ensure that the solar panels can be installed on the same plane exactly.

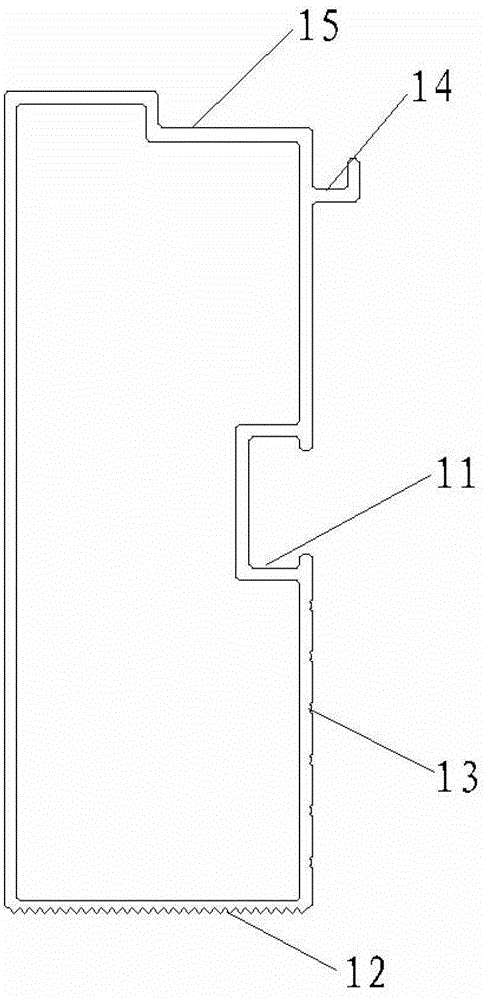

[0029] Please refer to figure 2 As shown, the inner side of the frame 1 is provided with a hook groove 11, and the screw 7 with the screw cap located in the hook gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com