Linear motor and compressor with same

A technology of linear motors and iron cores, applied in the field of electric motors, can solve problems such as limited motor travel, high control requirements, and difficult to guarantee size, and achieve the effects of improving structural processing accuracy, simplifying processing technology, and reducing control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

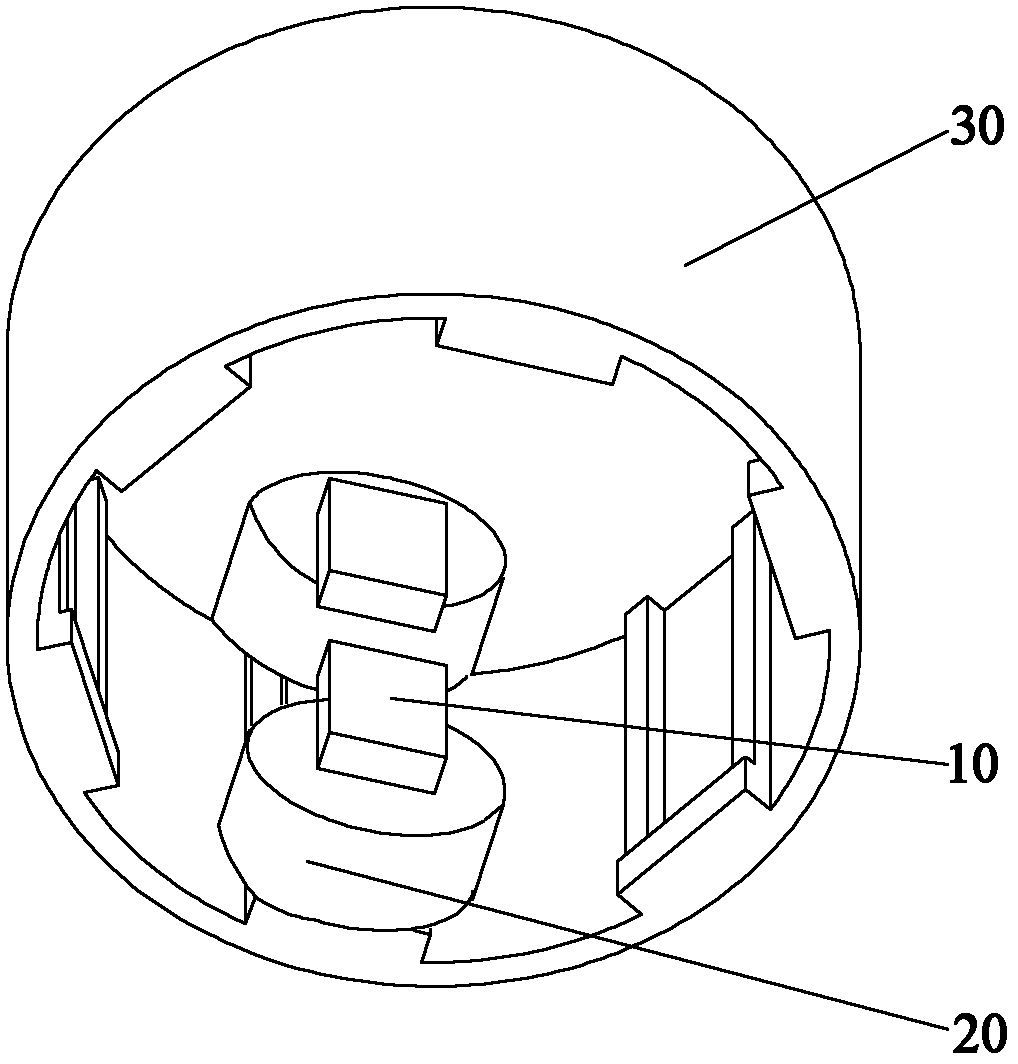

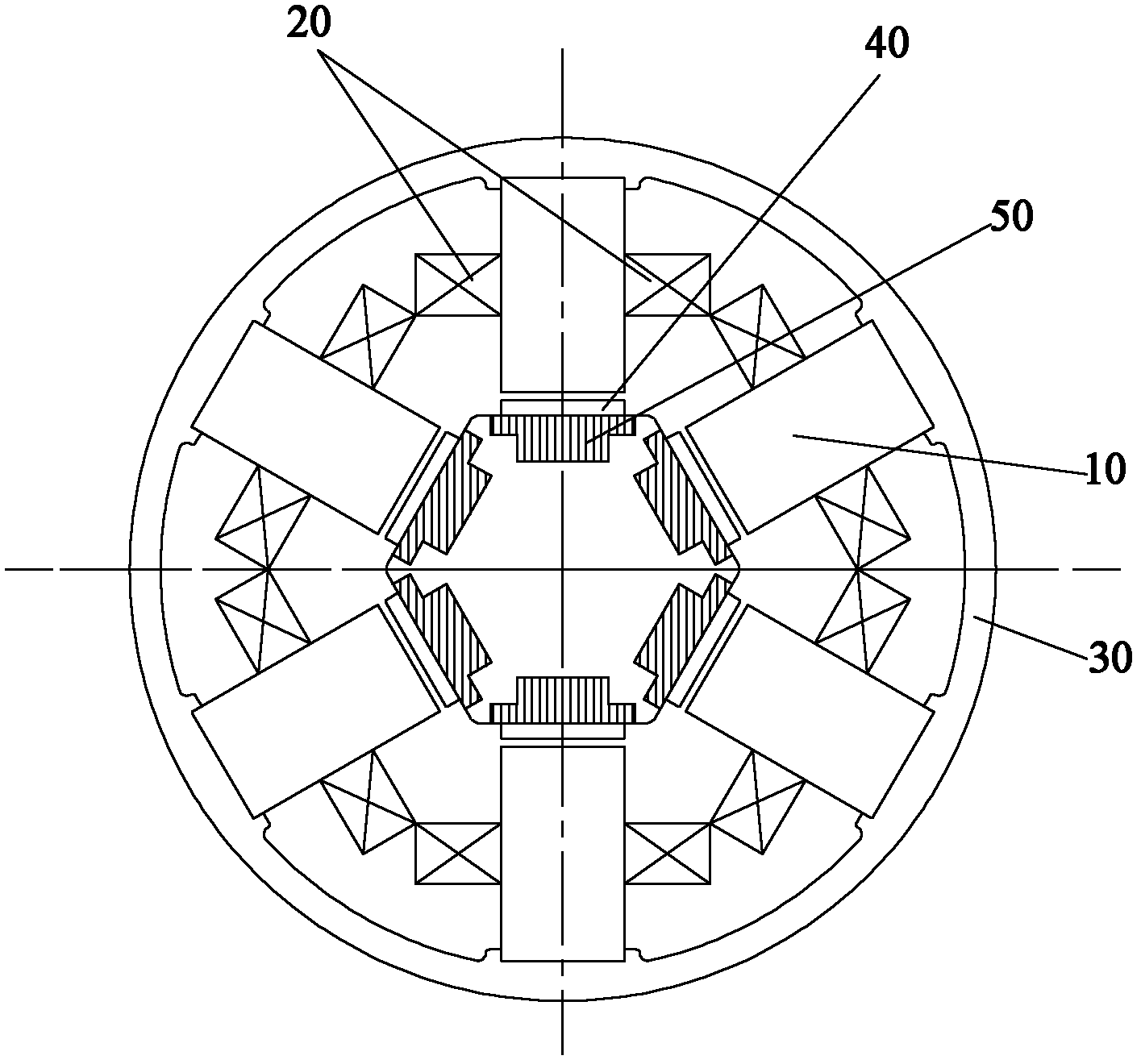

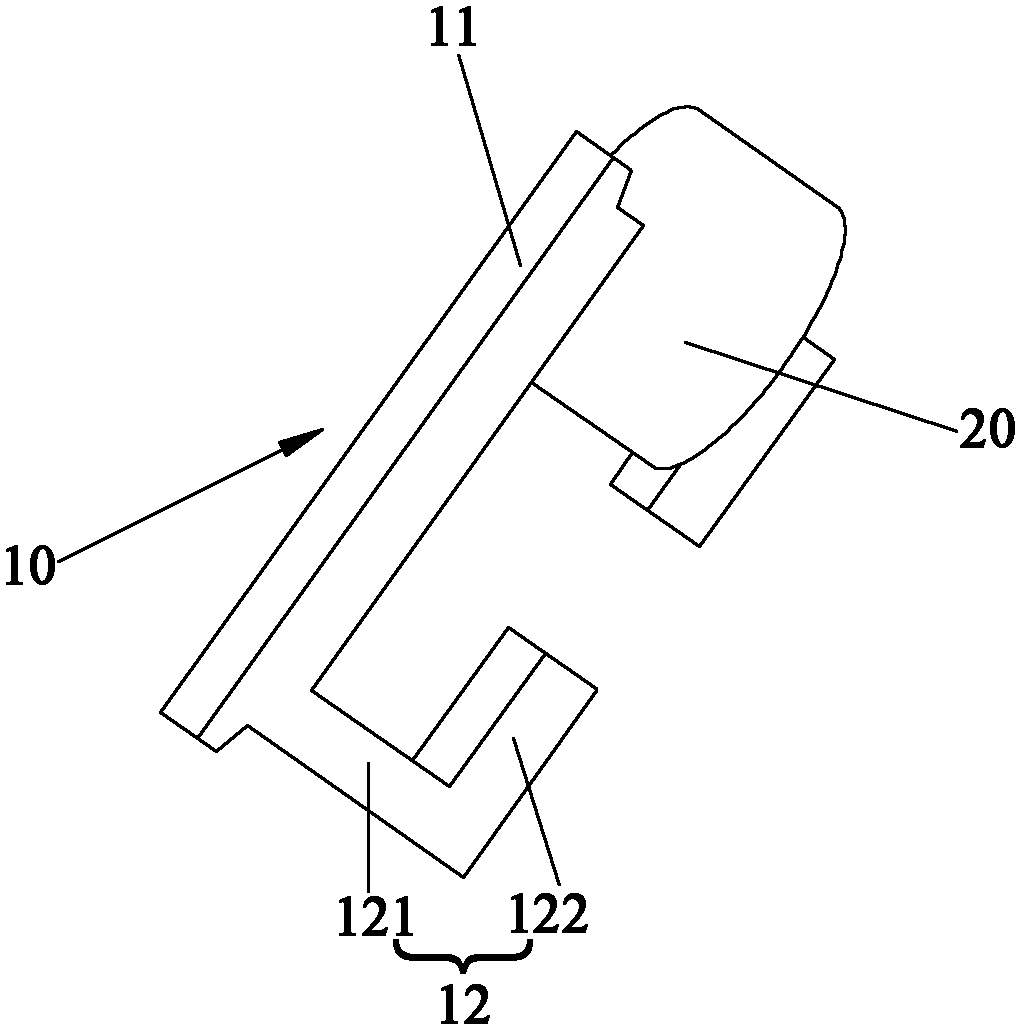

[0025] Such as figure 1 with figure 2 The shown linear motor according to the present invention includes a stator and a mover that reciprocates under the action of the stator. The stator includes: a stator core 10 including a core body 11 and two teeth extending outward from the core body 11 The shape part 12 , the core body 11 and the two tooth parts 12 are arranged so that the stator core 10 is C-shaped; the winding part 20 is respectively wound on each tooth part 12 .

[0026] Adopt the linear motor of the present invention, as image 3 As shown, the stator core 10 is C-shaped and includes two tooth-shaped parts 12, and the winding part 20 is respectively wound on the two tooth-shaped parts 12, and the winding process is relatively simple. Such as Figure 4 As shown, between the toothed portion 12 and the winding portion 20, an insulating layer 70 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap