Exhaust gas diffuser for a gas turbine and a method for operating a gas turbine that comprises such an exhaust gas diffuser

一种燃气轮机、扩散器的技术,应用在用于弹性流体的泵送装置的部件、机器/发动机、液体燃料发动机等方向,能够解决燃气轮机和加力燃烧室组合运行限制等问题,达到避免空气动力学损失、改进效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

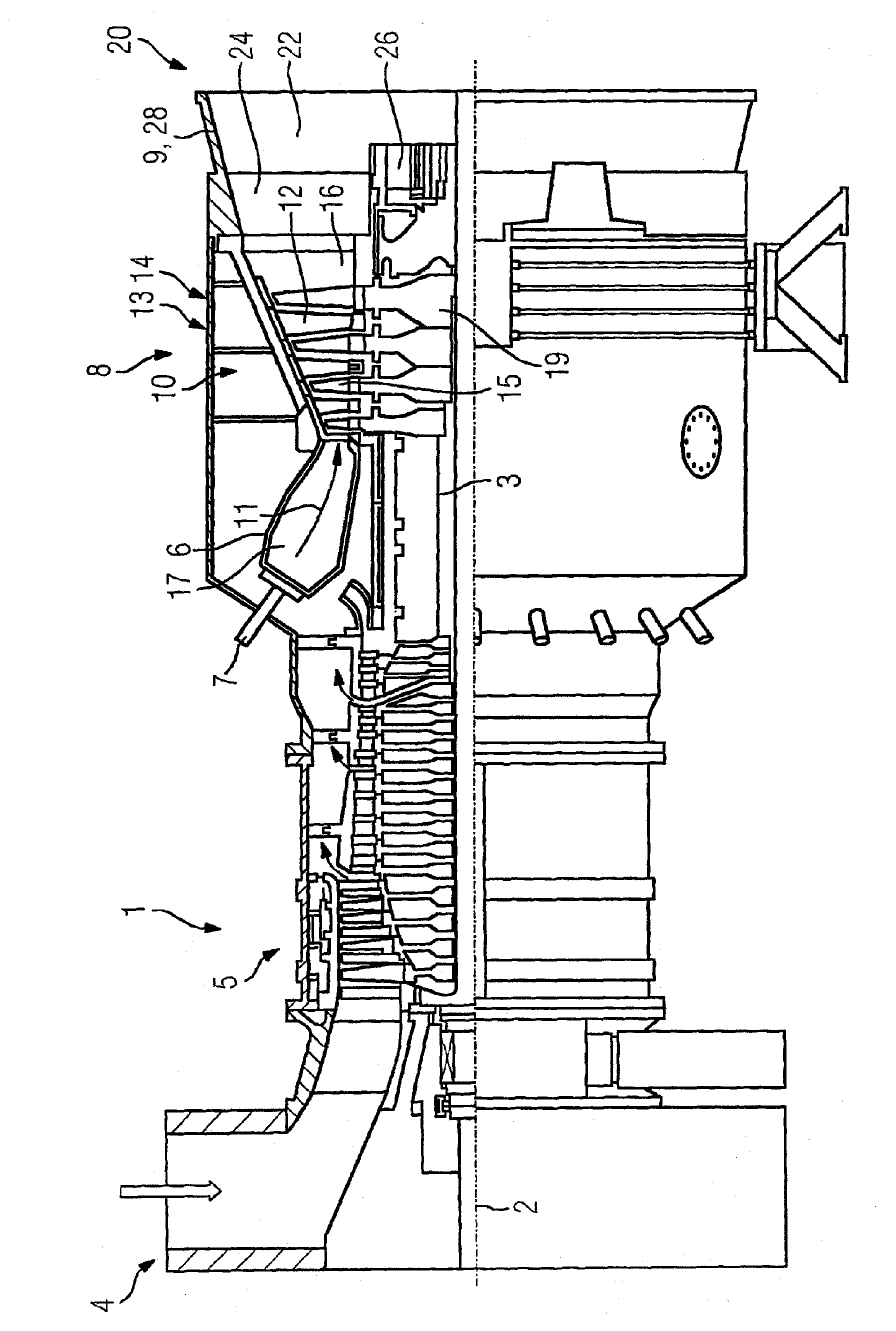

[0027] figure 1 A partial longitudinal section of the gas turbine 1 is shown. The gas turbine has an internally mounted rotor 3 rotatable about a machine axis 2 , which is also referred to as a turbine rotor. Along the rotor 3 there are an intake housing 4 , a compressor 5 , an annular annular combustion chamber 6 with burners 7 arranged rotationally symmetrically to one another, a turbine unit 8 and an exhaust housing 9 . The annular combustion chamber 6 surrounds a combustion chamber 17 which communicates with an annular hot gas channel 16 . There, four successively connected blade stages 10 form the turbine unit 8 . Each blade stage 10 is formed by two blade rings. Viewed in the direction of flow of the hot gas 11 generated in the annular combustion chamber 6 , the row 14 of rotor blades 15 each follows the row 13 of guide blades in the hot gas channel 16 . The guide blades 12 are fastened to the stator, whereas the rotor blades 15 of the rows 14 are each attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com