Near-infrared reflective film, method for manufacturing near-infrared reflective film, and near-infrared reflector

一种制造方法、近红外的技术,应用在反射/信号涂料、化学仪器和方法、涂层等方向,能够解决粒度分布广、涂膜变色、雾度高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0249] "Fabrication of near-infrared reflective film"

[0250] [Preparation of sample 1]

[0251] (high refractive index layer 1)

[0252] (Preparation of Coating Solution 1 for High Refractive Index Layer)

[0253] Coating liquid 1 for a high refractive index layer was prepared according to addition method A of the following addition sequence.

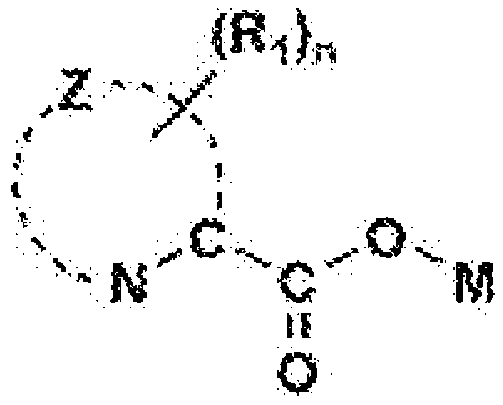

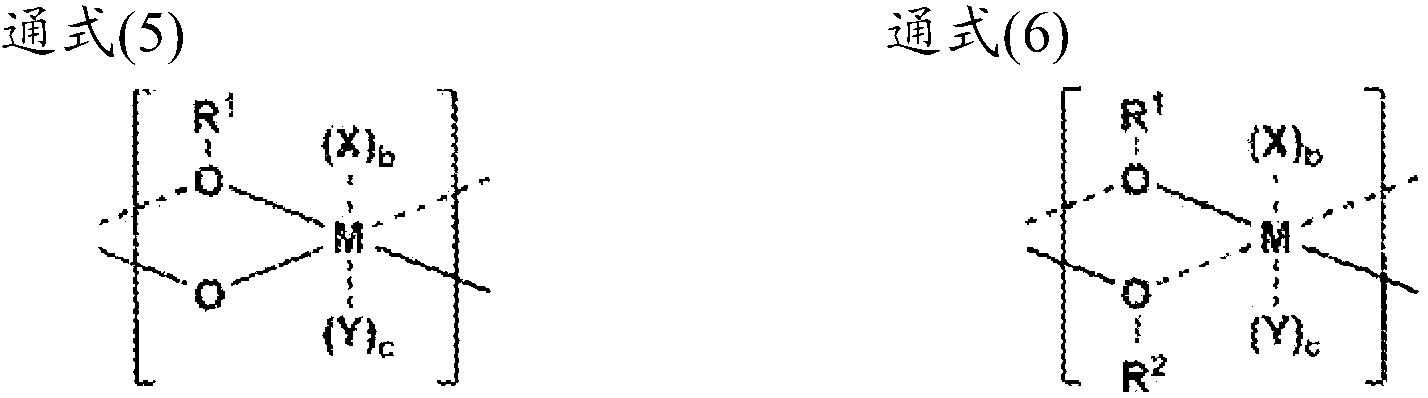

[0254] Dissolve 2.5 parts of tamarind gum as a thickening polysaccharide, 0.5 parts of polyvinyl alcohol (PVA203 manufactured by Kuraray Co., Ltd.), and 5.0 parts of LI-17 (aminocarboxylic acids) which is an exemplary compound of the compound A of the present invention. To the solution obtained in 340 parts of water, 5.0 parts of a 5.5 mass % aqueous solution of boric acid adjusted to pH 3.0 with nitric acid and 56 parts of a 20 mass % solution of the following rutile-type titanium oxide particle sol were added to prepare a coating for a high refractive index layer. cloth liquid 1.

[0255]

[0256] Under stirring, to the aqueou...

Embodiment 2

[0354] [Production of near-infrared reflector]

[0355] The near-infrared reflectors 1-18 were produced using the near-infrared reflective film of the samples 1-18 produced in Example 1. The near-infrared reflective films of samples 1-18 were respectively bonded to transparent acrylic resin plates with a thickness of 5 mm and 20 cm×20 cm with an acrylic adhesive to produce near-infrared reflectors 1-18.

[0356] [Evaluation]

[0357] The near-infrared reflectors 1 to 18 prepared above can be easily used despite the large size of the near-infrared reflectors, and excellent near-infrared reflectivity can be confirmed by using the near-infrared reflective film of the present invention.

Embodiment 3

[0359] "Fabrication of near-infrared reflective film"

[0360] [Preparation of sample 101]

[0361] (Preparation of High Refractive Index Layer Coating Liquid 101)

[0362] The following additives 1) to 6) were sequentially added and mixed to prepare a high refractive index layer coating liquid 101 .

[0363] First, the temperature was raised to 50° C. while stirring 1) the titanium oxide particle sol, and then 2) low-molecular-weight gelatin was added and stirred for 30 minutes to coat the surface of the titanium oxide particles with low-molecular-weight gelatin. Next, 3) polymer gelatin, 4) glycine, and 5) pure water were added and stirred for 90 minutes, and then 6) a surfactant was added to prepare a high refractive index layer coating liquid 101 .

[0364] 1) 20% by mass titanium oxide particle sol (volume average particle diameter 35nm, rutile type titanium oxide particles) 60g

[0365] 2) 5.0% by mass low molecular weight gelatin (Gel L1 ) aqueous solution 125g

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com