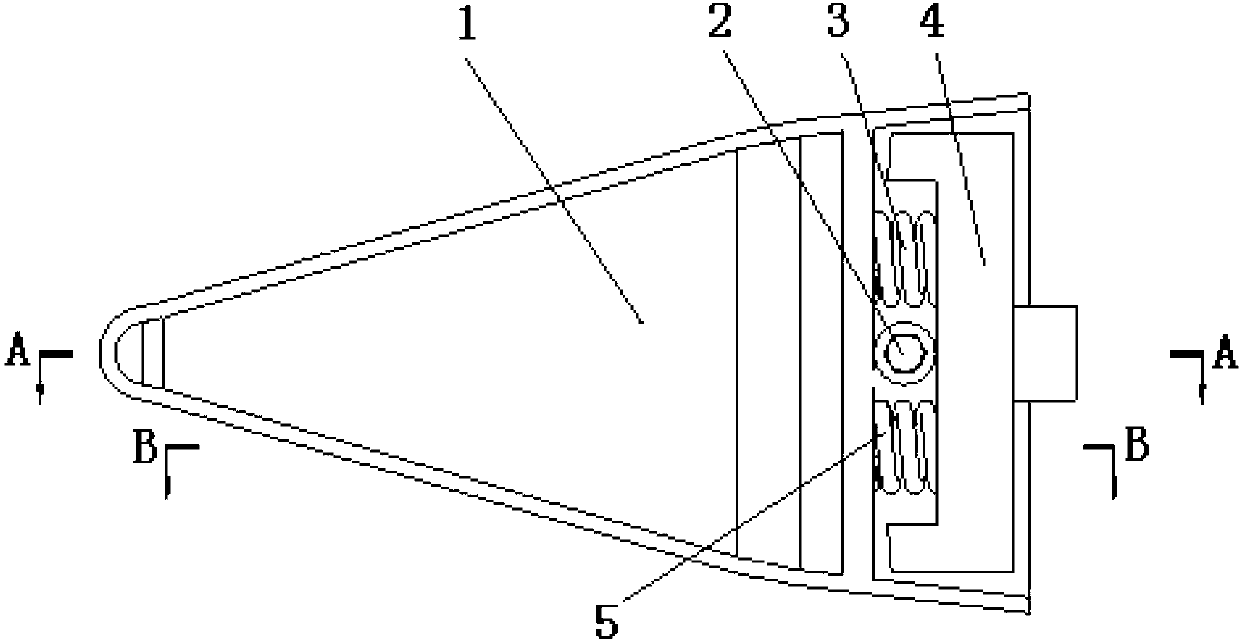

Non-side divider for no-row maize harvesting machine

A corn harvester and crop divider technology, applied in the directions of external crop dividers, harvesters, agricultural machinery and implements, etc., can solve the problems of overturning and breaking of corn stalks, reduce the expansion angle, avoid entanglement of weeds and corn stalks effect of leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

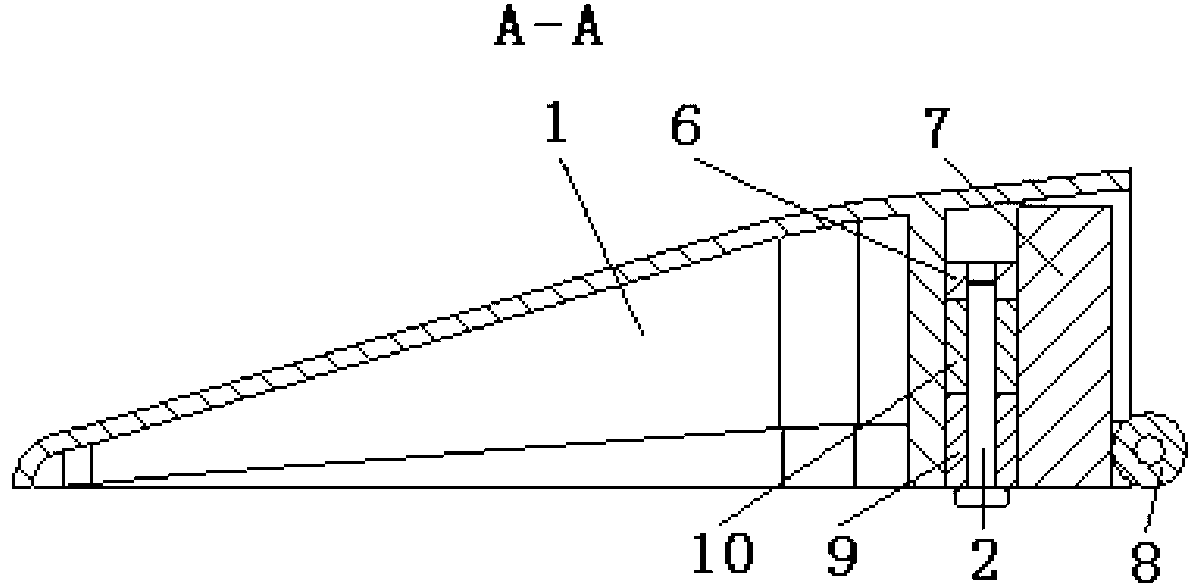

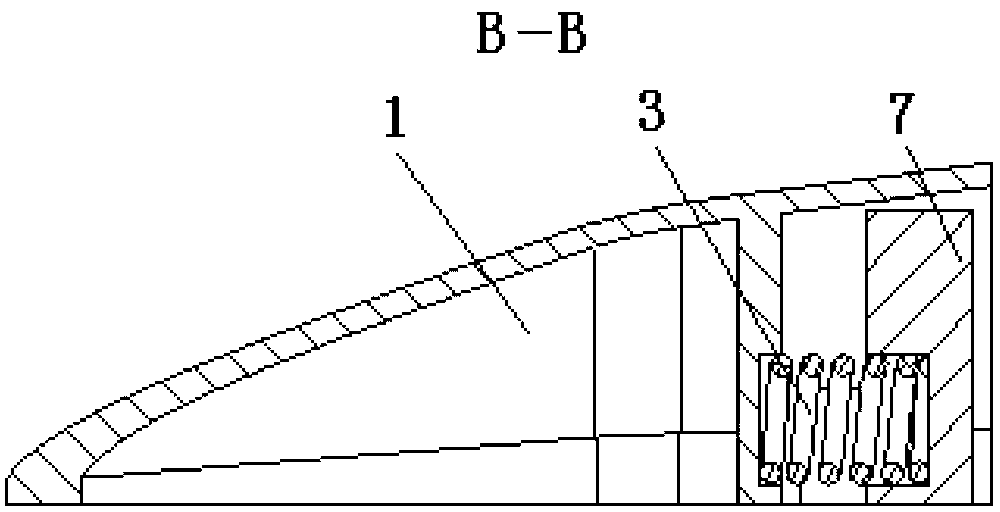

[0022] In the present invention, the two ends of the spring I 3 are respectively embedded in the spring groove I 11 of the cover plate 1 of the grain divider and the spring groove IV 15 of the connecting seat 4 of the grain divider, and the two ends of the spring II 5 are respectively embedded in the spring groove II 12 of the cover plate 1 of the grain divider and the spring groove III14 of the connecting seat 4 of the grain divider, so that the cover plate of the grain divider deviated from the center line can be reset; the sleeve I6 and the sleeve II9 at the bottom of the cover plate 1 of the grain divider are connected with the grain divider through the connecting pin 2 The sleeve pipe III10 of seat 4 is flexibly connected.

[0023] The front end of the grain divider cover plate 1 is a quarter of a spherical shell with a diameter of 60mm. Place the grain divider cover plate 1 in the xyz space Cartesian coordinate system, the center of the spherical shell coincides with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com