Method for eliminating facility cultivated vegetable continuous cropping obstacle and application of method

A technology of facility cultivation and continuous cropping obstacles, applied in the agricultural field, can solve the problems of environmental pollution, fruits and vegetables, growth retardation, pesticide residues, etc., and achieve the effects of improving the soil micro-ecological environment, slow root growth, and promoting decomposition and transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

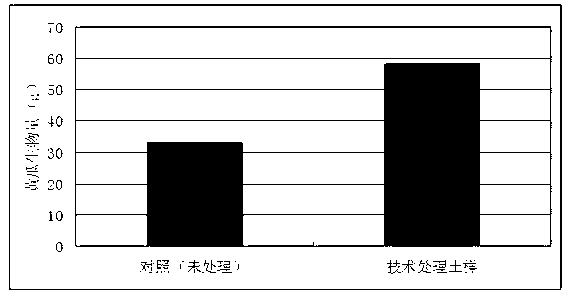

Image

Examples

Embodiment 1

[0024] 1) In June after the tomato harvest in the greenhouse, remove the tomato stumps in the field, and stack wheat straw or straw piles with a length of 5 meters, a width of 3 meters, and a height of 1 meter on the ground, and cut the straw or wheat straw into 20 cm long; Mix 5 kg of quicklime for every 1000 kg of straw in the process of haystacking;

[0025] 2) Build a dam around the greenhouse, the dam height is 20 cm, and irrigate to make the surface water in the shed 10 cm higher than the surface, and keep the water level basically unchanged. Apply 50 g / mu of ferrous sulfate to the surface, and soak the haystack in water at the same time , surrounded by a shed, sealed, and exposed to the sun for 10 days;

[0026] 3) After 10 days, uncover the greenhouse, ventilate and ventilate, drain the accumulated water in the field, turn over the haystack after 7 days, mix 2 kg of urea evenly for every 1000 kg of haystack, keep the humidity of the haystack at 50%, and inoculate straw...

Embodiment 2

[0030] 1) In May after the harvest of cucumbers cultivated in greenhouses, remove the cucumber stumps in the field, and stack straw piles with a length of 3 meters, a width of 4 meters, and a height of 1.2 meters on the surface, and cut the straw into 25 cm long; For every 1000 kg of straw mixed with 3.5 kg of quicklime;

[0031] 2) Build a dam around the greenhouse with a dam height of 20 cm. Irrigate with water so that the water surface in the shed is 10 cm higher than the ground surface, and keep the water level basically unchanged. Apply 500 g / mu of ferrous sulfate to the ground surface and soak the haystack at the same time. In the water, the four sides are covered with a shed, sealed, and exposed to the sun for 14 days;

[0032] 3) After 14 days, uncover the greenhouse, ventilate, drain the accumulated water in the field, turn over the haystack after 10 days, mix 5 kg of urea evenly into every 1000 kg of haystack, keep the humidity of the haystack at 40%, and inoculate s...

Embodiment 3

[0036] 1) In late August after harvesting watermelons in greenhouses, remove watermelon residues in the field, and stack straw piles with a length of 2.5 meters, a width of 3.5 meters, and a height of 1.5 meters on the surface, and cut the straw into 25 cm long; During the haystacking process, mix 5 kg of quicklime for every 1000 kg of straw;

[0037] 2) Build a dam around the greenhouse with a dam height of 20 cm. Irrigate with water so that the water surface in the shed is 10 cm above the ground surface, and keep the water level basically unchanged. Apply 1000 g / mu of ferrous sulfate to the ground surface and soak the haystack at the same time. In the water, the four sides are covered with a shed, sealed, and exposed to the sun for 12 days;

[0038] 3) After 12 days, uncover the greenhouse, ventilate and ventilate, drain the accumulated water in the field, turn over the haystack after 14 days, mix 3 kg of urea evenly into every 1000 kg of haystack, keep the humidity of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com