Sand-bath type wheat frying machine

A wheat frying machine and sand bathing technology, applied in application, food preparation, food science and other directions, can solve the problems of waste of manpower and material resources, insufficient energy saving and environmental protection, heat waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

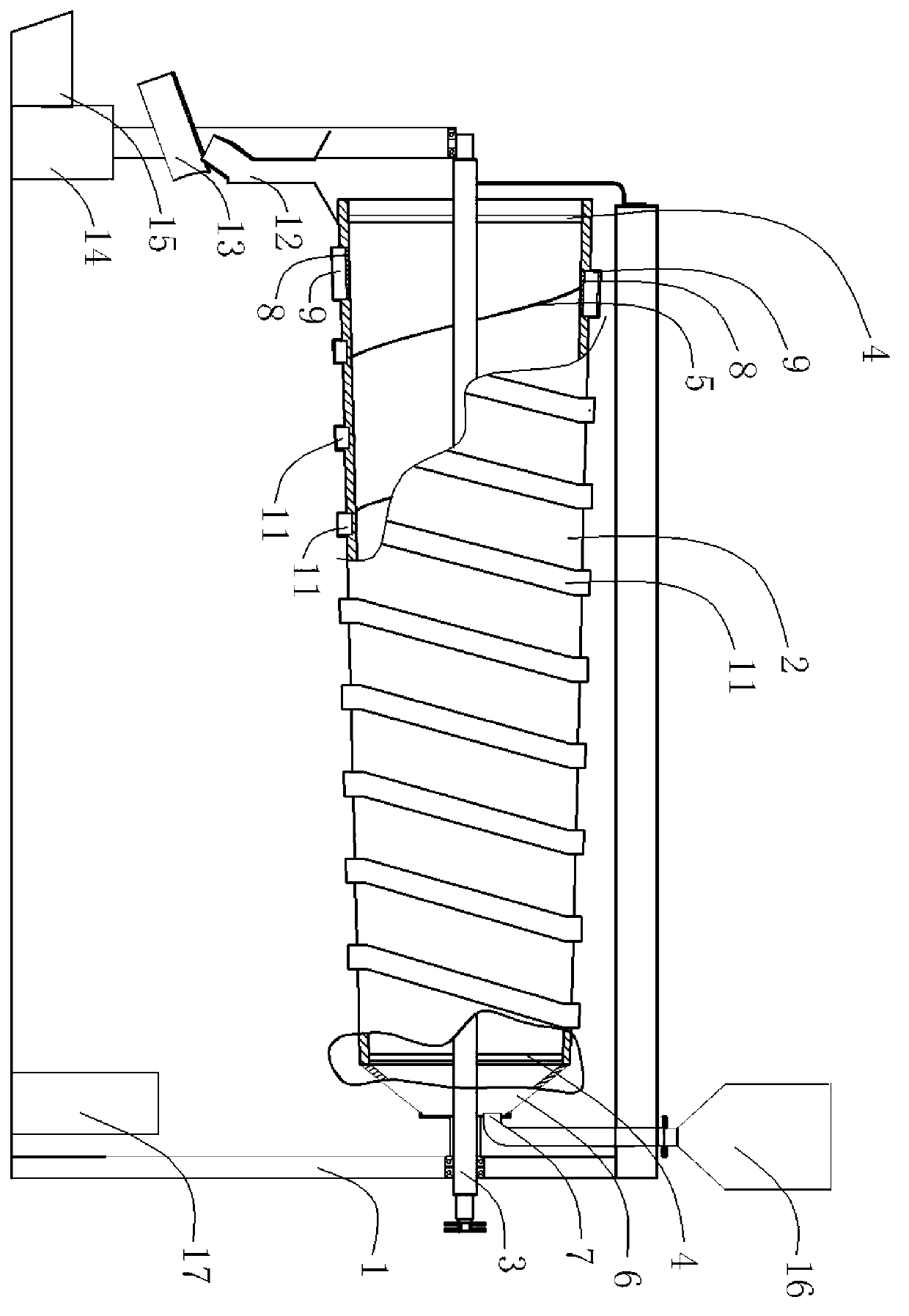

[0013] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0014] Such as figure 1 As shown, the sand-bathed wheat frying machine of the present invention includes a frame 1, a cylinder body 2, a rotating shaft 3, a feed cover 6 and a drive motor 17, the left and right ends of the cylinder body 2 are open, and the cavity of the cylinder body 2 The outer contour is a circular frustum arranged horizontally, its large end is facing left, and the rotating shaft 3 is arranged horizontally. The rotating shaft 3 is fixedly installed in the cavity of the cylinder body 2 through several connecting rods 4, and is located on a section of the rotating shaft 3 inside the cylinder body 2. There are spiral blades 5, the two ends of the rotating shaft 3 protrude from the cylinder body 2, the two ends of the rotating shaft 3 are respectively installed on the frame 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com