New technology for improving tobacco stalk pulping quality

A new technology, the technology of tobacco stems, applied in the field of new pulping technology, can solve the problems of high content of fine fibers and short pulping fibers, and achieve the effect of improving tensile strength, reducing dosage, and reasonable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

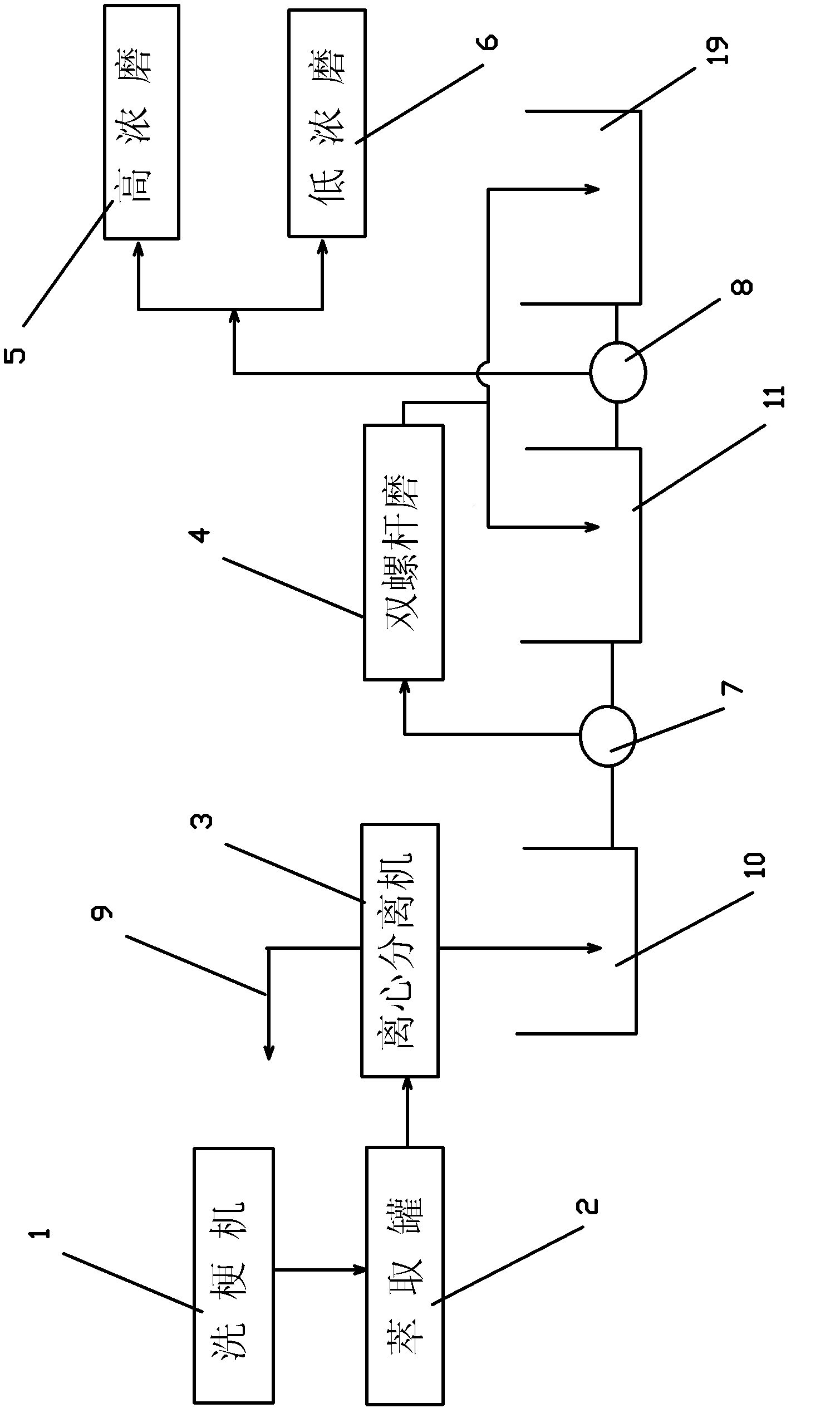

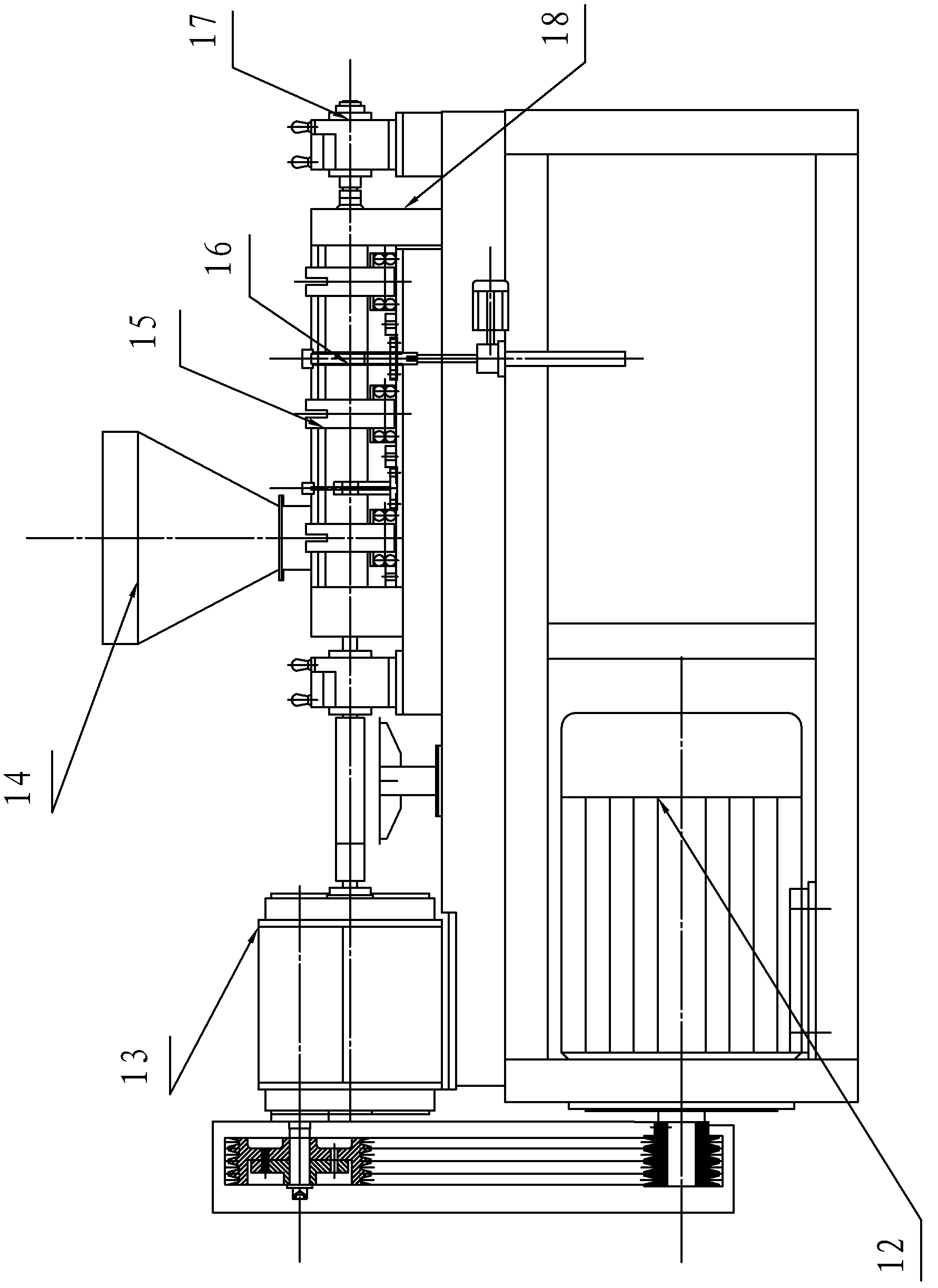

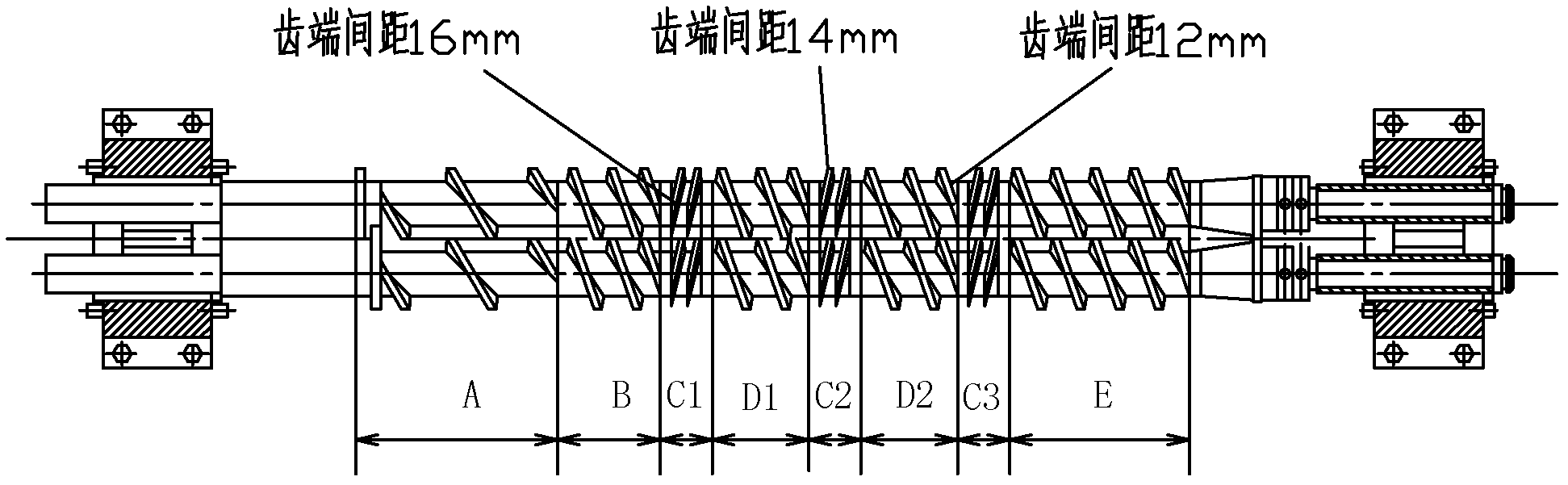

Embodiment 1

[0046] In the production process of reconstituted tobacco by papermaking, the raw tobacco stems are washed first, and the washed tobacco stem materials are sent to the extraction tank by the belt conveyor, and the extracted tobacco stem materials are separated by a centrifugal separator for solid-liquid separation Then use TSD-CMP pretreatment. The diameter of the twin screw used in this example is Φ80mm, the screw speed is 300rpm, the compression ratio of the front section is 3:1, and the rear section is not compressed; the blade distance is 16mm, 10mm and 8mm. Set of spiral knives, in which the knife edge distance of the first squeezing, tearing and kneading zone is 16mm, the second squeezing, tearing and kneading zone is 10mm, and the third is 8mm. The entire TSD-CMP pretreatment process is cycled twice, most of the fibers are separated, and the fiber length is kept high, some of the fibers have been fibrillated, and the beating degree of the pulp is 25°SR. The pretreated to...

Embodiment 2

[0056] In the production process of reconstituted tobacco leaves by papermaking, after solid-liquid separation of the extracted tobacco stem material by a centrifugal separator, the tobacco stem material is pretreated with TSD-CMP. The screw diameter is Φ80mm and the screw speed is adjusted to 200rpm. The front section has a compression ratio of 3:1, and the rear section has no compression; three sets of spiral blades are selected as 12mm, 10mm and 8mm blade distance. Among them, the first section of squeezing and tearing and kneading zone is 12mm, and the second section is squeezing and tearing. The knife edge distance is 10mm, and the knife edge distance in the third stage of squeezing, tearing and kneading zone is 8mm; the entire TSD-CMP pretreatment process is cycled twice, most of the fibers are separated, and the fiber length is kept high, and some of the fibers have been thinned. The beating degree of pulping is 20°SR. The pre-treated tobacco stem pulp is pulverized by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com