Dust recovery device and recovery method of hygiene products

A technology for dust recovery and sanitary products, which is applied in the direction of separation methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of low recovery and utilization rate of fluff pulp, reduce the quality of sanitary products, and small dust removal area, so as to increase filtration Surface area, long service life, effect of reducing filtration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

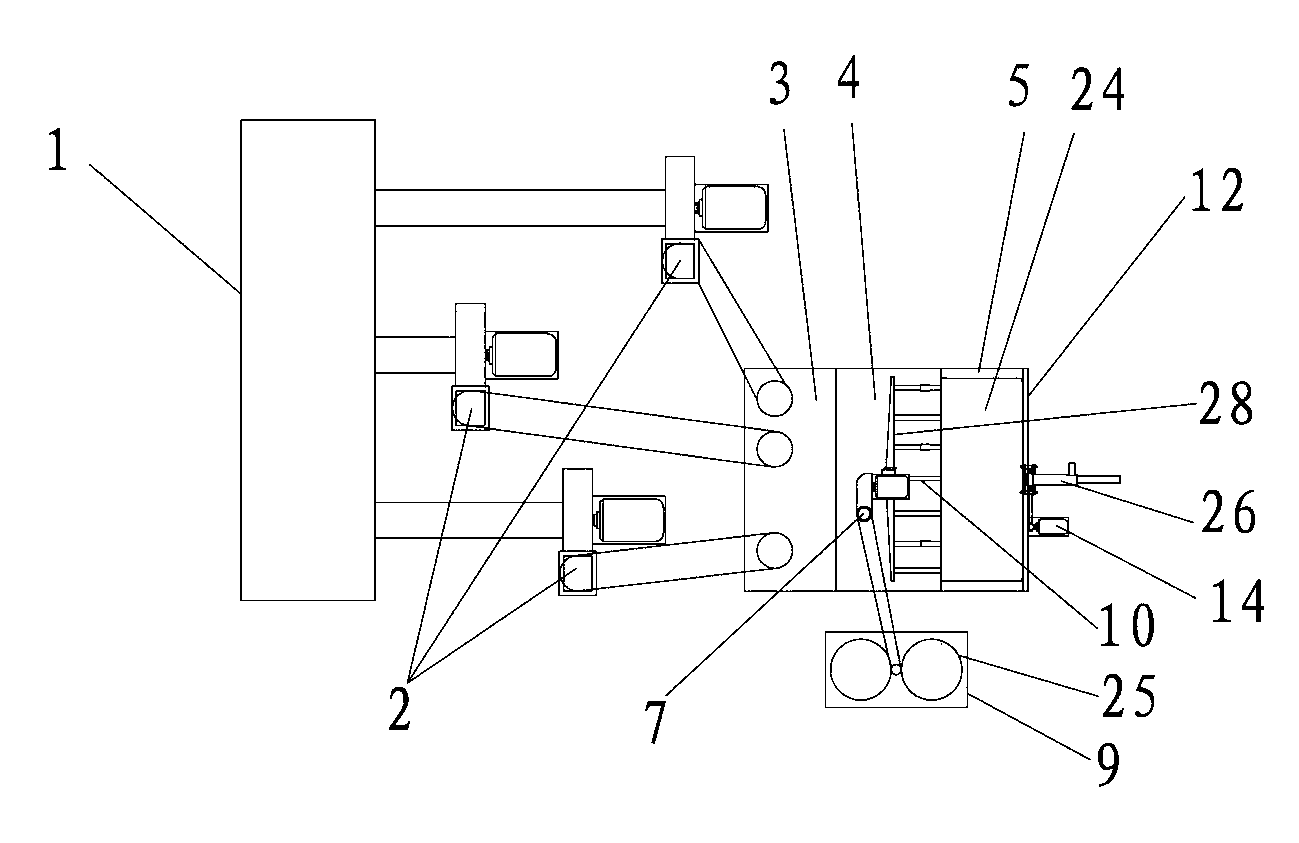

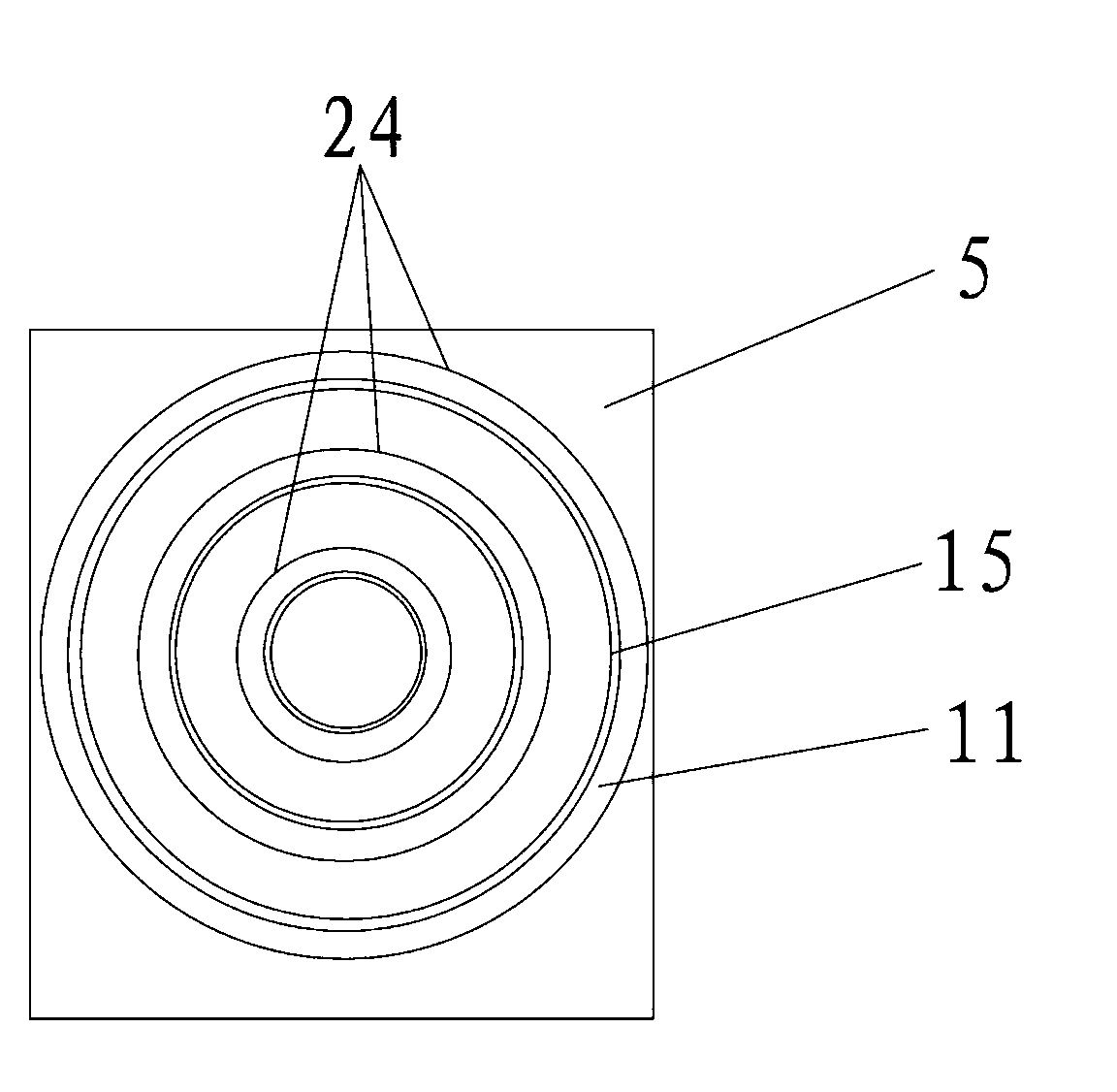

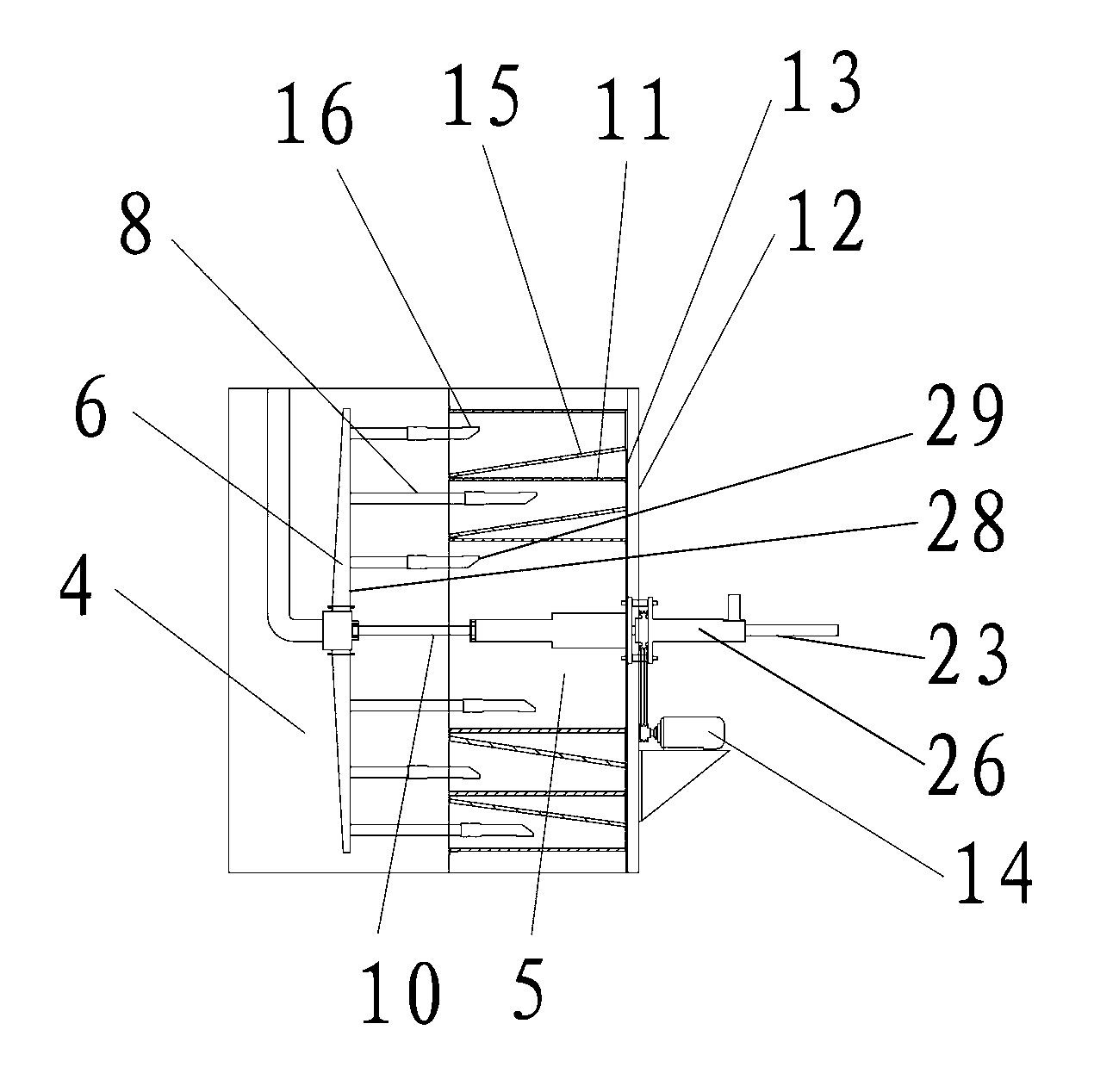

[0024] combine figure 1 , figure 2 with image 3 , a dust recovery device for sanitary products, comprising a sanitary product production line 1, a dust recovery device and a dust box 9, a number of suction fans 2 are arranged at intervals along the sanitary product production line 1, and the dust recovery device consists of a left box body 3, a middle box body 4 and the right box 5 are arranged and assembled; the air outlets of the suction fan 2 are connected with the left box 1; the middle box is provided with a dust suction device 28, and the dust suction end 29 of the dust suction device 28 extends into the right box Inside the body 5 and extends to between two adjacent filter devices 24, a dust suction fan 7 is arranged on the outside of the middle box body 4, one end of the dust suction fan 7 is connected with the dust collection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com