Special processing technology for angular contact precision bearing cage

A technology of precision bearings and processing technology, applied in the field of processing technology of precision bearing cages, can solve problems such as difficult bearing cages, loss of isolation, and inability to complete processing, so as to eliminate processing stress, improve production efficiency, and eliminate positioning effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

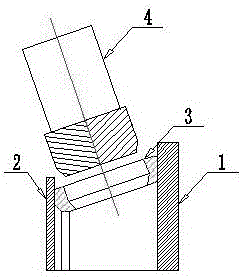

[0009] The specific embodiment of the present invention is: the cage 3 is fixed on the positioning tire seat 1 at one time, the cage 3 is pressed with the positioning tire cover 2, and four empty sipes of each pocket are firstly processed on the solid cage 3 ;Eliminate the probability of interpenetration of empty sipes, and then use the empty sipes as the boring reference, start boring, and bore to the position close to the empty sipes. After eliminating most of the processing pocket stress, use four empty sipes One of the empty sipes in is used as the starting reference to start machining pockets with milling cutter 4 until the last pocket is machined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com