Lifting type idler wheel conveyor for chain transfer

A lifting and conveyor technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems affecting the efficiency and quality of item transfer operations, slow transfer speed, and low operating efficiency, and achieve smooth and safe item transfer. , low cost, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

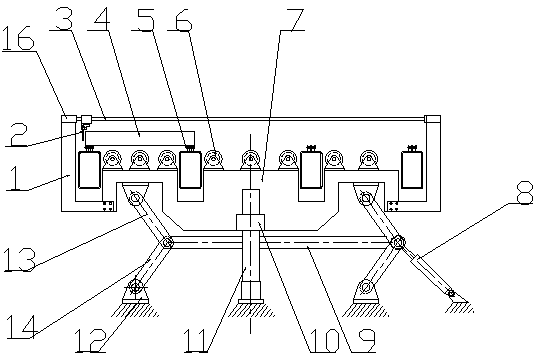

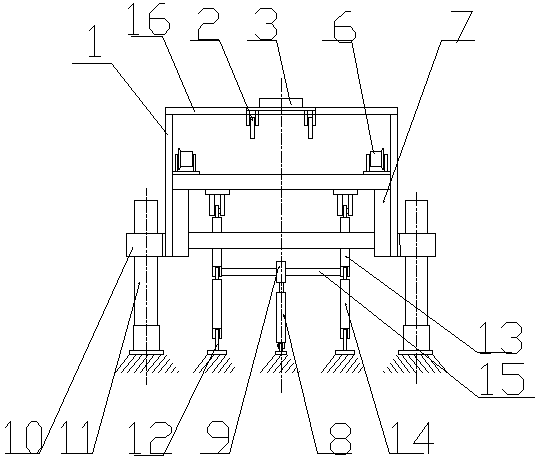

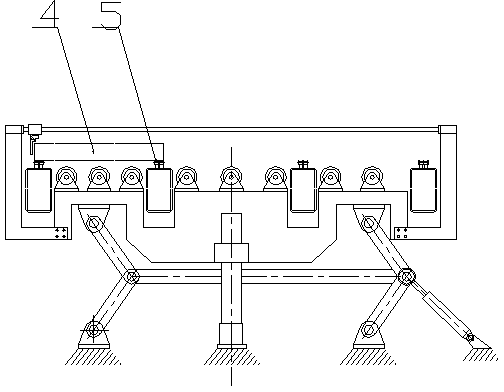

[0016] From Figure 1-Figure 6 It can be seen from the figure: a lifting roller conveyor for chain transmission (referred to as roller conveyor), which is characterized in that: the lifting roller conveyor for chain transmission is mainly composed of a roller conveying device, a connecting rod lifting device and a guiding device. The roller conveying device is mainly composed of frame 7 (conveying frame), roller 6, roller seat, cylinder support 1, rodless cylinder 3 and shift fork 2, and the frame 7 is mainly composed of a frame and a platform plate. The steel structure frame is welded by symmetrically arranged left and right longitudinal beams and front and rear cross beams, and the upper part of the frame is symmetrically spaced with upper U-shaped grooves in the front and rear directions. Ⅰ , this upper U-shaped groove Ⅰ The chain 5 used for the chain conveyor carrying the items 4 to be transferred passes through, and the lower part of the frame is correspondingly locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com