Flame retardant modified MDI and preparation method thereof

A modification and modifier technology, applied in the field of flame retardant modified MDI and its preparation, can solve the problems of harsh storage and use conditions and operating process requirements, and achieve the effects of not easy to ignite and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 8.1Kg reactive flame retardant modifier RB-79 and 4.9Kg high molecular weight reactive cell opener DK-12 into the reaction kettle, stir and heat up to 110°C, adjust the vacuum degree to -0.095MPa, and dehydrate for 2 hours while stirring , and then lower the temperature to 40°C, add 2g of phosphoric acid and stir evenly, and keep it sealed. Add 28.5Kg of pure MDI, 26Kg of MDI-50 and 32.5Kg of PM-200 into the reaction kettle, add the dehydrated mixed modifier while stirring, slowly raise the temperature to 65°C, keep the temperature for 2 hours, and take samples for detection NCO% was 26.8, cooled to 45°C, discharged and sealed for storage.

Embodiment 2

[0018] Add 10.4Kg of reactive flame retardant modifier RB-7980 and 4Kg of high molecular weight reactive pore opener DK-12 into the reactor, stir and heat up to 100°C, adjust the vacuum to -0.095MPa, and dehydrate for 2 hours while stirring. Then lower the temperature to 40° C., add 1.8 g of phosphoric acid, stir evenly, and seal it for storage. Add 28Kg of pure MDI, 25.6Kg of MDI-50 and 32Kg of PM-200 into the reaction kettle, add the dehydrated mixed modifier while stirring, slowly raise the temperature to 70°C, keep the temperature for 1.5 hours, and take samples to detect NCO % was 26.5, cooled to 45°C, discharged and sealed for storage.

Embodiment 3

[0020] Add 3.9Kg of reactive flame retardant modifier RB-79, 5.5Kg of RB-7970, and 6.3Kg of high molecular weight reactive cell opener DK-12 into the reactor, stir and raise the temperature to 100°C, and adjust the vacuum degree to -0.095MPa , dehydrated for 2 hours while stirring, then cooled to 40°C, added 1.5g of phosphoric acid and stirred evenly, sealed and stored. Add 27.6Kg of pure MDI, 25.2Kg of MDI-50 and 31.5Kg of PM-200 into the reaction kettle, add the dehydrated mixed modifier while stirring, slowly raise the temperature to 80°C, keep the temperature for 1 hour, and take a sample The NCO% was detected to be 26.1, the temperature was lowered to 45°C, and the material was discharged and sealed for storage.

[0021]

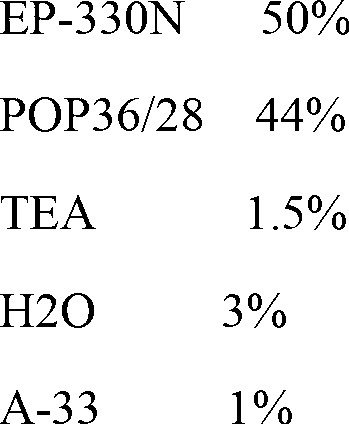

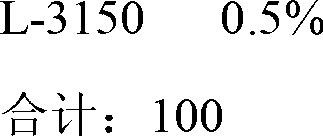

[0022] The formula of high resilience A material used above is as follows (by weight percentage):

[0023]

[0024]

[0025] Compared with the existing modified MDI product (patent CN101353413 product), the present invention has simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com