Pressure-sensitive adhesive tape for battery

A technology of pressure-sensitive adhesives and pressure-sensitive adhesives, which is applied in the direction of adhesive types, battery pack parts, ester copolymer adhesives, etc., and can solve the problems of difficulty in maintaining battery output, electrolyte degradation, and slow battery degradation and other issues, to achieve high stability and reliability, excellent productivity, and the effect of suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] 2 parts by weight of an isocyanate crosslinking agent (trade name: "CORONATE L", manufactured by Nippon Polyurethane Industry Co., Ltd.), followed by dilution with toluene to obtain a pressure-sensitive adhesive (1).

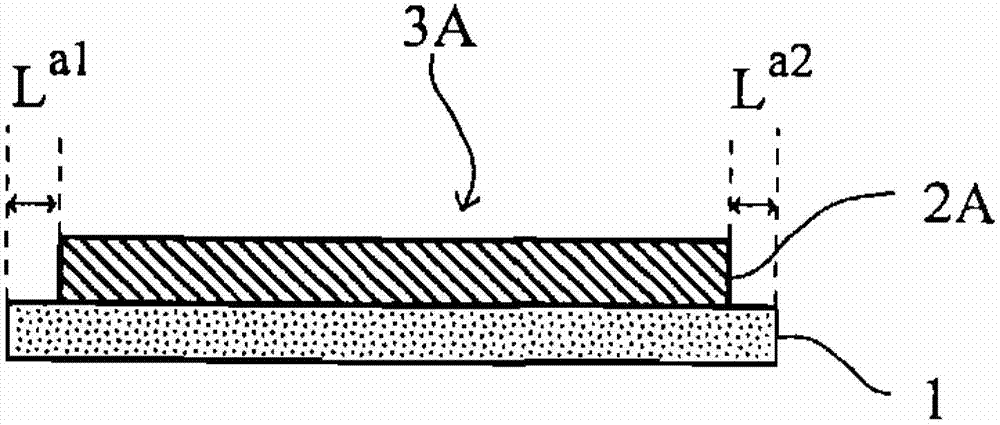

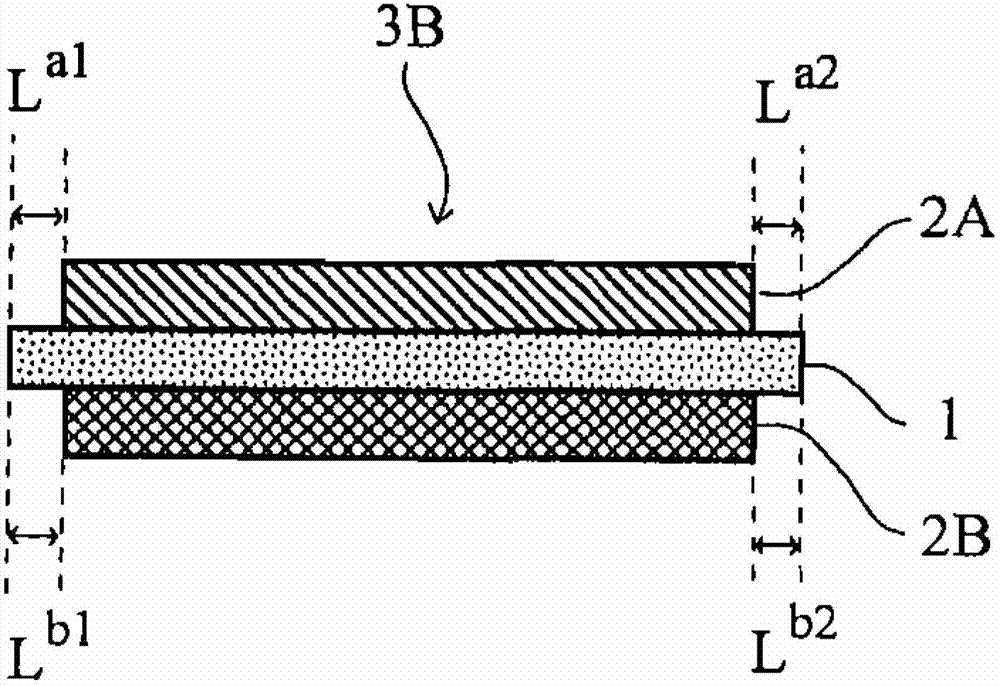

[0085] The obtained pressure-sensitive adhesive (1) was applied to the inside of a biaxially stretched polypropylene film (OPP) having a thickness of 20 μm at a distance of 0.5 mm from both side edges thereof so that the thickness after drying was 15 μm, and This was dried to prepare a pressure-sensitive adhesive tape (1).

Embodiment 2

[0087] A pressure-sensitive adhesive tape (2) was prepared in the same manner as in Example 1 except that the thickness of the pressure-sensitive adhesive layer after drying was changed from 15 μm to 2 μm.

Embodiment 3

[0089] A pressure-sensitive adhesive tape (3) was prepared in the same manner as in Example 1 except that the thickness of the pressure-sensitive adhesive layer after drying was changed from 15 μm to 45 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com