Drilling fluid for ultra deep well

A drilling fluid and ultra-deep well technology, applied in the field of ultra-deep well drilling fluid, can solve the problems of poor rheology and wall-building properties of drilling fluid, poor coordination, poor rheology of drilling fluid, etc., achieve low formation pollution, improve The effect of high drilling speed and high mud cake strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

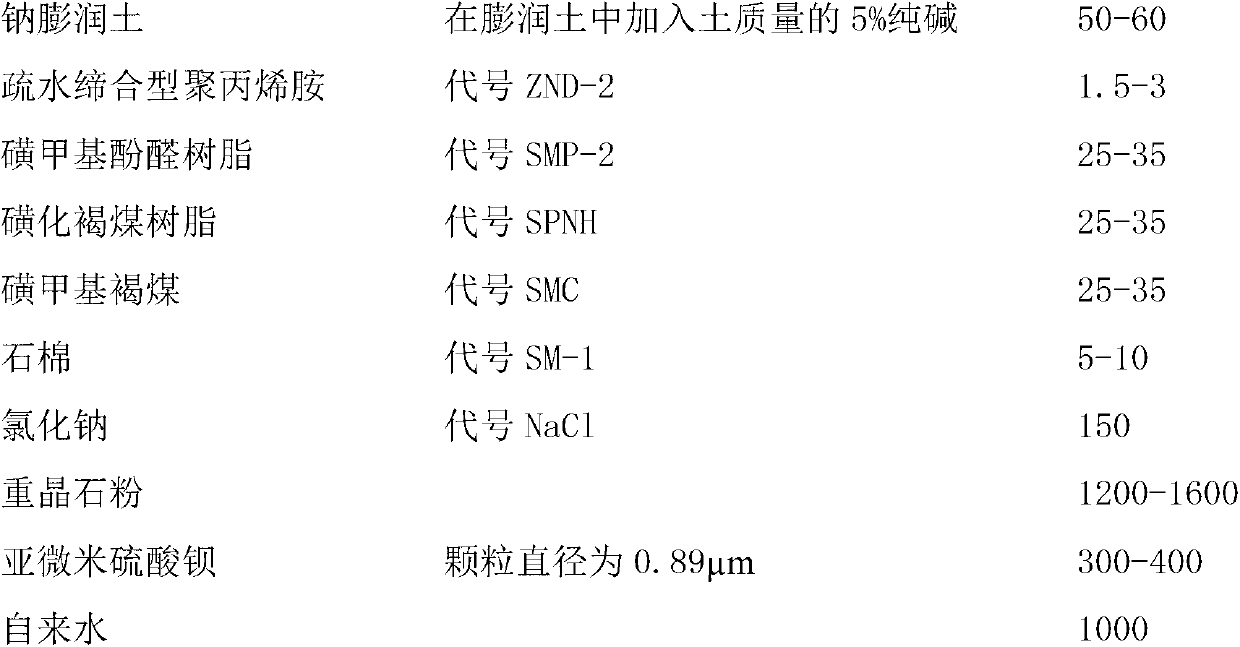

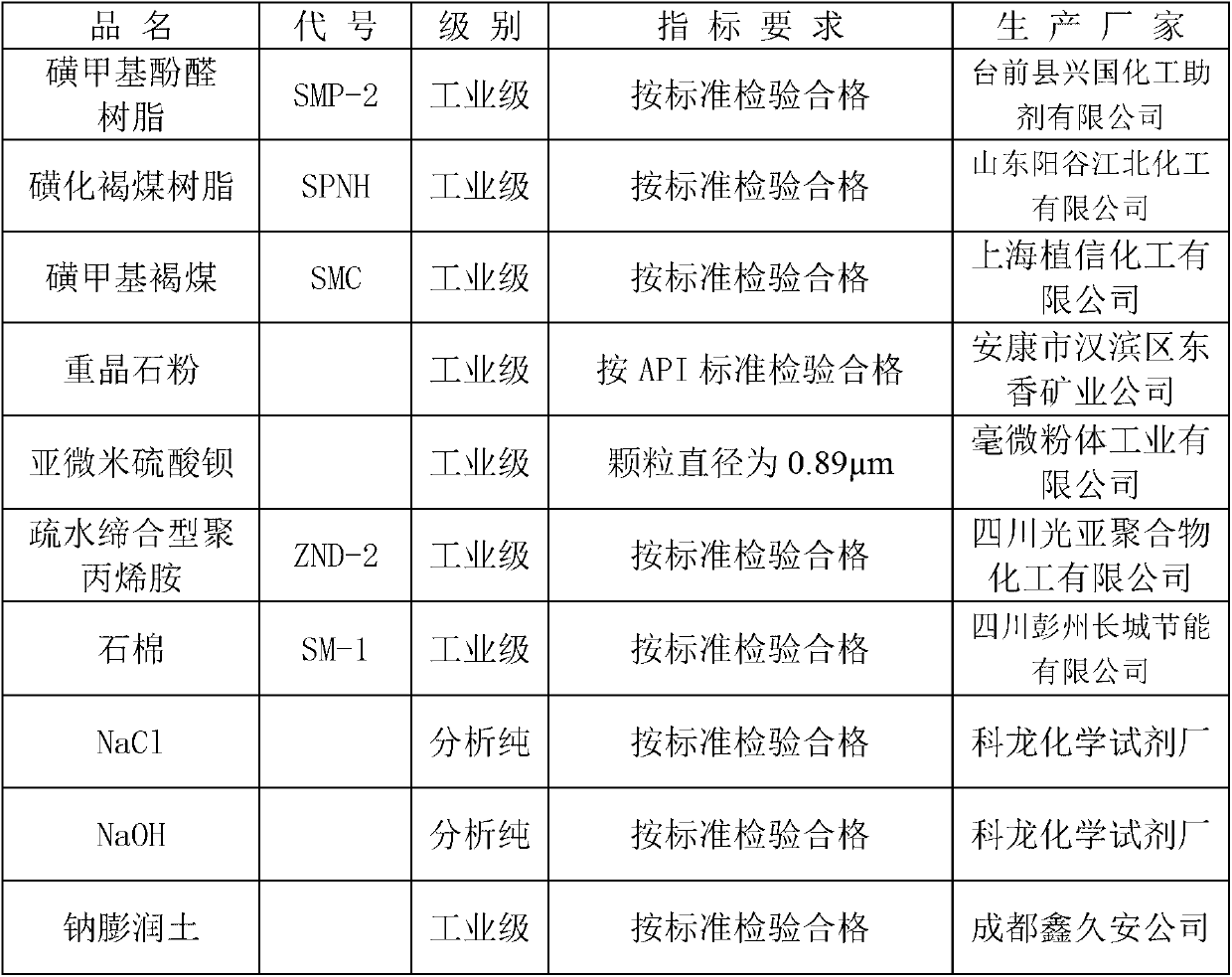

[0011] The specific preparation method of the ultra-deep well drilling fluid

[0012] The preparation method of the ultra-deep well drilling fluid is as follows: first step, add 1000 grams of tap water and 50 grams of sodium bentonite to the reaction vessel, stir at low speed for 120 minutes, stir at high speed for 60 minutes, and then maintain at room temperature for 24 hours; Under electric stirring, add 1.5 grams of hydrophobic association polyacrylamine ZND-2 in turn, stir for 20 minutes, add 25 grams of sulfomethyl phenolic resin SMP-2, stir for 20 minutes, add 25 grams of sulfonated lignite resin SPNH, stir for 20 minutes, add 25 gram of sulfomethyl lignite SMC, stirred for 20 minutes, added 5 grams of asbestos SM-1, stirred for 20 minutes, added 150 grams of sodium chloride NaCl, stirred for 30 minutes; in the third step, slowly added the mass percent The pH of the system is adjusted to 10 with 40% NaOH, and the stirring is continued for 15 minutes; the fourth step is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com