Method for preventing water storage in strong or weak current well

A technology of strong and weak electricity and pools, applied in water conservancy projects, waterway systems, and sewage discharge, etc., can solve problems such as threats, equipment failure, and insufficient attention to waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

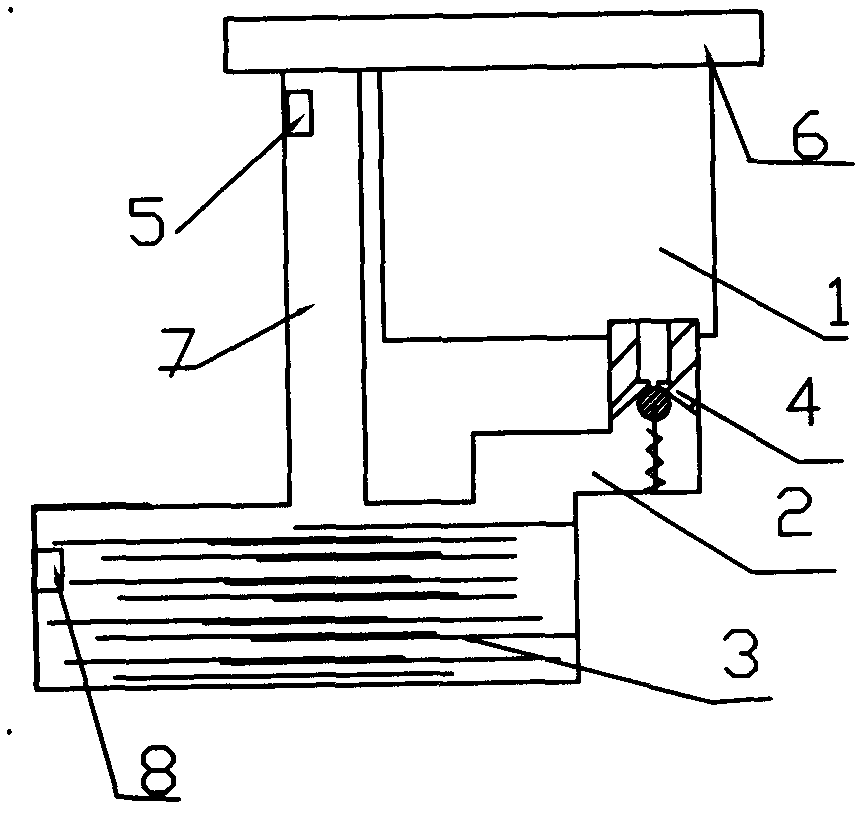

[0007] The method of preventing water from being stored in strong and weak electric wells, from figure 1 What you can see: Take the cement pouring forming inspection well as an example, the steps are: 1. In the inspection well, seal the channeling pipe and the main well wall that have been passed into the well with rubber rings, and finally apply sealant, and each single threading pipe is also sealed at the same time. The sealant is good. 2. Make a hole under the main well body and make a water pipe with plastic pipe or other pipes. 3. Install a reverse water stop device (float valve) in the water pipe at the bottom of the main well body while connecting. or electromagnetic valve), 4. Cut a brick under the main well body or pour cement into a storage tank below the horizontal line of the main well, and connect and seal the water pipeline of the main well, and install a water level switch in the main well. 5. Another storage tank Make a pumping pipeline with a plastic pipe or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com