Cruciform member module

A cross-shaped component technology, which is applied in the field of cross-shaped component modules, can solve problems such as unsuitable cross connections and no blocks provided, and achieve the effects of ensuring wall section size, sufficient blending, and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

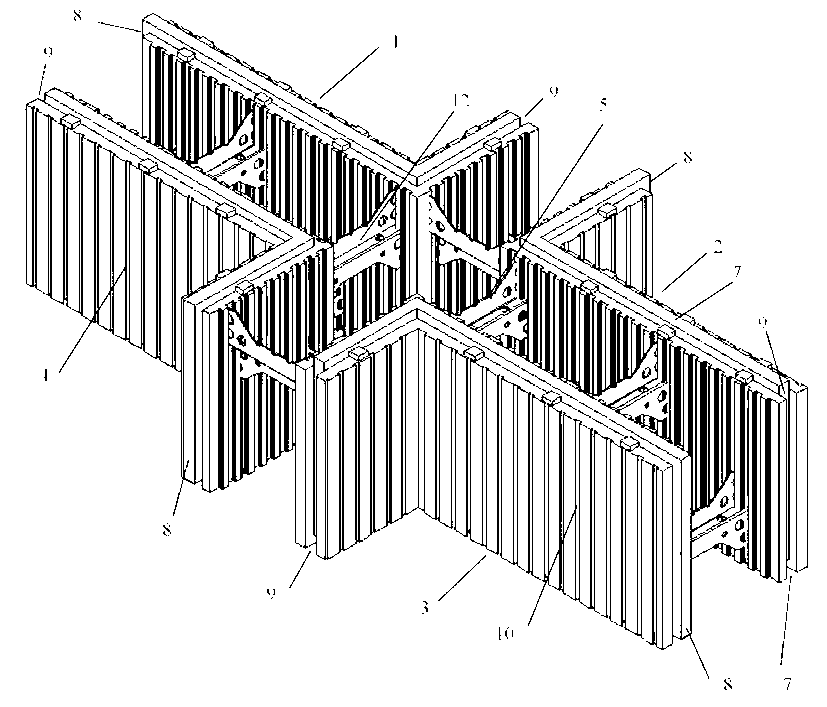

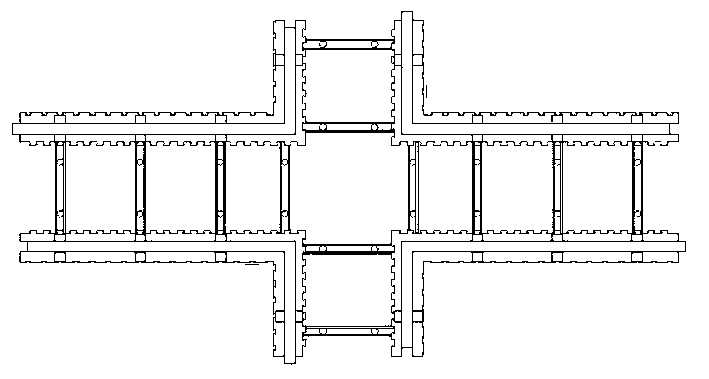

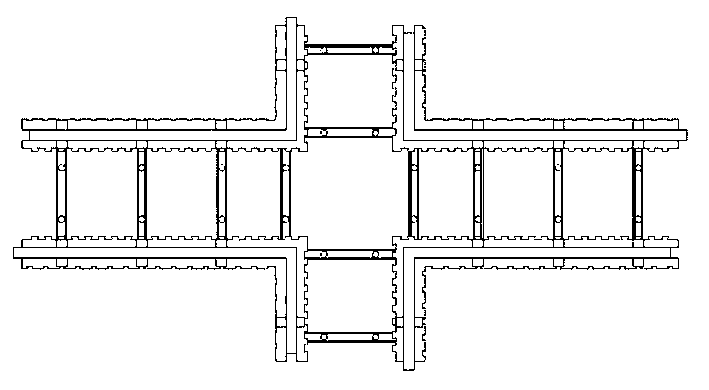

[0010] Specific implementation mode one: as Figure 1-7 As shown, a cross-shaped component module described in this embodiment is composed of four module corner plates 1, 2, 3, 4 and a plurality of core ribs 12; the four module corner plates 1, 2, 3, 4 (right angle board) is made of thermal insulation material; the four module corner plates 1, 2, 3, 4 are arranged in a cross shape, and a plurality of misplaced core ribs are set in the cross-shaped inner cavity formed by the four module corner plates. Two adjacent module angle plates are connected by core ribs 12, and a plurality of core ribs form vertical and horizontal flower holes; the plurality of core ribs 12 are connecting members having the same function as steel bars.

specific Embodiment approach 2

[0011] Specific implementation mode two: as Figure 1-9 As shown, the core rib 12 in this embodiment is composed of two core rib side plates 12-1 and a core rib main board 12-2, and the core rib main board 12-2 is composed of two sub-boards 12-2 with the same length. 2-1 and transition plate 12-2-2, the two sub-plates 12-2-1 are arranged in a staggered butt joint, and the two are connected through the transition plate 12-2-2 to form a stepped shape, and the core rib main plate 12-2 The stepped end surfaces at both ends are respectively connected with a core rib plate 12-1. The main plate of the core rib is stepped (with roundabout part: transition plate 12-2-2). The core rib of this structure has strong resistance to deformation and bending, which greatly improves the load-bearing capacity of the wall. When the four module corner plates 1, 2, 3, 4 and the plurality of core ribs 12 are integrally formed in the present invention, the core rib main board 12-2 is inlaid or fixed ...

specific Embodiment approach 3

[0012] Specific implementation mode three: as Figure 1-9 As shown, in this embodiment, the outer side of one sub-board 12-2-1 of the two core rib side boards 12-1 is connected with a reinforcing bar position groove 5. Other components and connections are the same as those in the second embodiment. Rib plates 12-3 may also be provided between the stepped end surfaces at both ends of the core rib main plate 12-2 in this embodiment and the core rib side plate 12-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com