Method for rapidly removing multilayer monolithic main wall through eccentric whole dumping

A load-bearing wall and integral technology, applied in building maintenance, construction, building construction, etc., can solve the problems of low demolition efficiency, high demolition cost, and low recyclability of load-bearing walls, and achieve high demolition efficiency, low demolition cost, The effect of high rebar recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

[0018] A method for quickly dismantling a multi-layer single-piece load-bearing wall by eccentric overall toppling, comprising the following steps:

[0019] a. Remove indoor and outdoor water sources, power supplies, doors and windows, pipelines, railings, insulation and decoration;

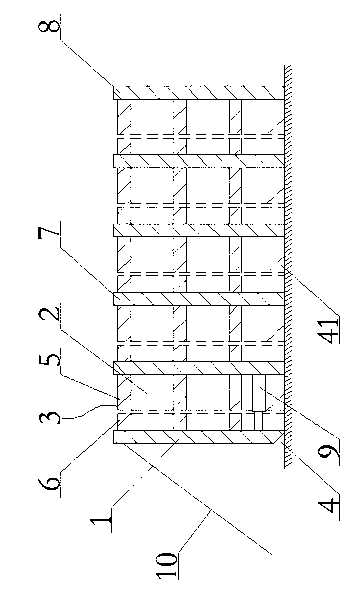

[0020] b. According to the direction parallel to the load-bearing wall, the eaves wall 2 and the floor 3 between the two adjacent load-bearing walls are chiseled to form a split joint, and the eaves wall ring beam and the floor steel bar are retained, so that two by two The eaves wall and the floor between the adjacent load-bearing walls are divided into a large width part 5 and a small width part 6 of different widths. The large width part 5 and the small width part 6 are respectively connected between two adjacent load-bearing walls. All 6-eave walls and floor slabs of the small width p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com