Variable frequency drive shield thrust hydraulic system

A hydraulic system and variable frequency drive technology, applied in fluid pressure actuating devices, mining equipment, servo motors, etc., can solve the problems of low energy efficiency and large coupling between partitions, achieve high energy efficiency, good energy saving effect, and solve the problem of flow coupling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

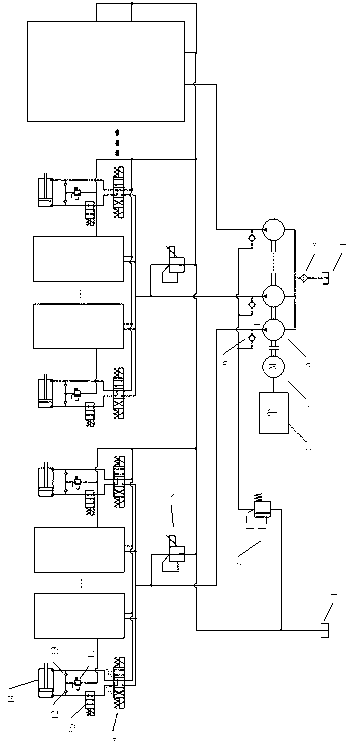

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] The present invention comprises oil tank 1, filter 2, frequency converter 3, frequency conversion motor 4, n quantitative pumps 5, n one-way valves 6, safety valve 7, n propulsion partitions with the same structure; the input end of frequency conversion motor 4 and The inverter 3 is connected, the output end of the variable frequency motor 4 is cascaded with n quantitative pumps 5, the oil inlets of n quantitative pumps 5 are connected to the oil tank 1 through filter 2, and the oil outlets of n quantitative pumps 5 are divided into two ways , one way is connected with the oil inlet of the respective one-way valve 6, and the other is connected with the respective propulsion partitions with the same structure, and the oil outlets of the n oil supply check valves 6 are connected to the oil inlet of the safety valve 7, The oil outlet of the safety v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com