Composite control hydraulic system for position and speed in rotation movement of duct piece assembly

A technology of rotary motion and speed control, applied in fluid pressure actuation devices, shaft equipment, wellbore lining, etc., can solve the problems of difficult segment precise positioning, large energy loss of valve control system, large rotation angle, etc., to achieve accurate The effect of positioning, avoiding valve control loss, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

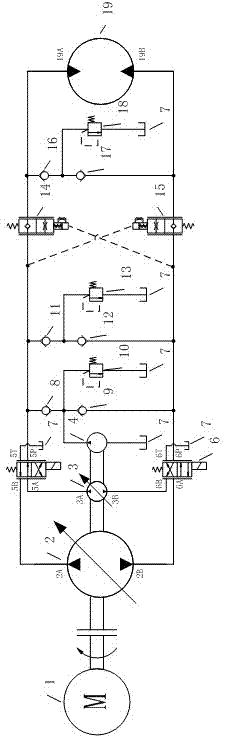

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] A position and speed compound control hydraulic system for segment assembly rotary motion, characterized in that it includes: motor 1, speed control variable pump 2, position control variable pump 3, oil replenishment quantitative pump 4, A-side two-position two-way electromagnetic reversing valve 5. B-side two-position two-way electromagnetic reversing valve 6, fuel tank 7, A-side oil supply check valve 8, B-side oil supply check valve 9, oil-fill overflow valve 10, A-side system check valve 11, B-side system check valve 12, system safety valve 13, A-side balance valve 14, B-side balance valve 15, A-side execution check valve 16, B-side execution check valve 17, execution safety valve 18, quantitative motor 19; Electric motor 1, speed control variable pump 2, position control variable pump 3 and oil charge quantitative pump 4 are cascaded, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com