Anti-negative pressure lined PTFE material shrimp elbow

A technology of shrimp elbow and fluorine material, applied in elbows, pipes/pipe joints/fittings, pipes to prevent damage/wear, etc., can solve the problems of material leakage, corroded steel parts, poor adhesion, etc., to simplify processing Process, improve the service life, not easy to crack and damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

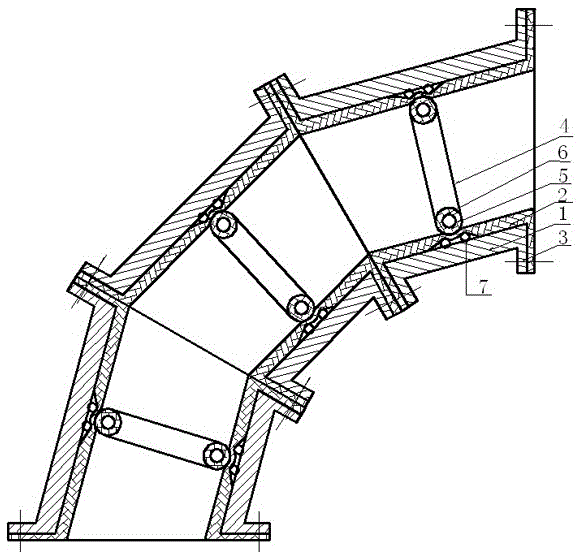

[0016] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features and effects of the anti-negative pressure lined shrimp elbow with tetrafluoroethylene material proposed by the present invention will be described in detail below.

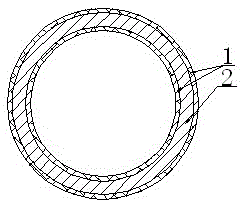

[0017] see Figure 1-2 , an anti-negative pressure shrimp elbow lined with PTFE material, comprising a steel shrimp joint 1 and a PTFE lining layer 2, wherein: the steel shrimp joint 1 is a tube with a trapezoidal cross-section, and the nozzles at both ends are provided with flanges. Lan 3, the PTFE lining layer 2 is lined on the inner wall of the steel shrimp joint 1 pipe, and at least two steel shrimp joints 1 lined with the PTFE lining layer 2 are connected to form an elbow. The negative pressure ring 4 is fixed in the middle of the inner surface of the PTFE lining layer 2 . The negative pressure ring 4 is made by putting the fluorine material casing 5 on the outer surface of the round st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com