Refrigerator container threading structure

A technology for box and refrigerator, applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems of difficulty in threading, prolonging the waiting time, and accelerating the aging of wiring harnesses, so as to optimize the process and eliminate aging. Problems, the effect of purifying the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

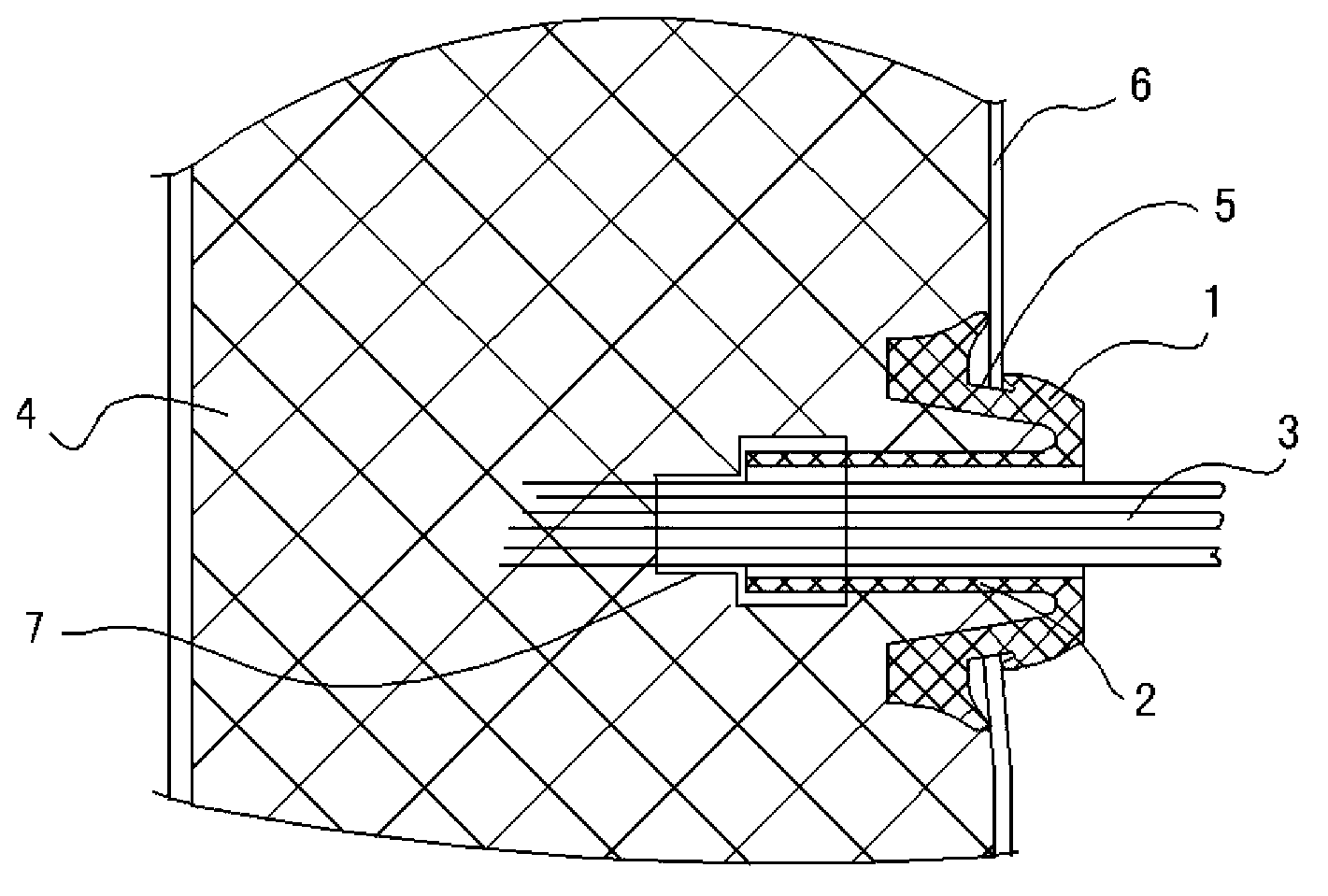

[0018] see figure 1 , the threading structure of the refrigerator box in this embodiment is set as follows: an extended wire harness sleeve 2 is integrated in the outer sleeve 1, the wire harness 3 passes through the central through hole of the wire harness sleeve 2, and the wire harness sleeve 2 is outside The end is flush with the outer sleeve 1 and connected, and the inner end of the wire harness sleeve 2 is pre-buried in the foam layer 4 of the refrigerator.

[0019] In the specific implementation, an annular groove 5 is provided on the outer circumferential surface of the outer sleeve 1, and the refrigerator tank 6 is inserted into the position of the annular groove 5, so that the outer sleeve is fixed; the central through hole of the wire harness sleeve 2 is provided The cross-section of the wire harness is circular. Keeping an appropriate gap in the wire harness perforation can facilitate threading and improve work efficiency. then fixed.

[0020] The assembly process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com