Usage of indophenol salt in direct dyeing in situ

A technology of indoxyl salt and potassium indoxyl, which is applied in the directions of indole-indigo dyes, dyeing methods, textiles and papermaking, etc., can solve the problems such as the purification method of indoxyl salt that are not mentioned, and achieve improvement Effects of absorption and impregnation ability, shortening of dyeing time, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

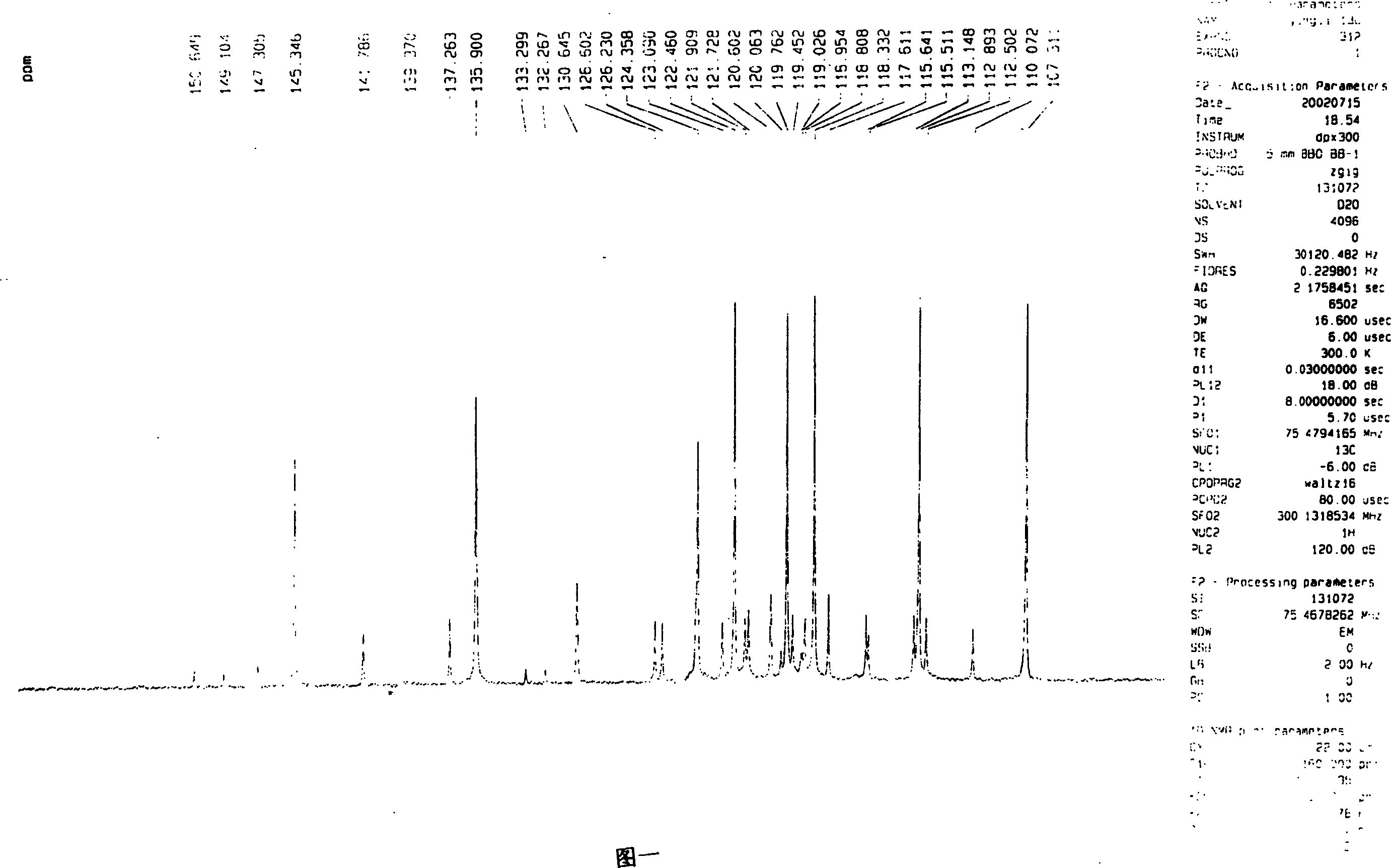

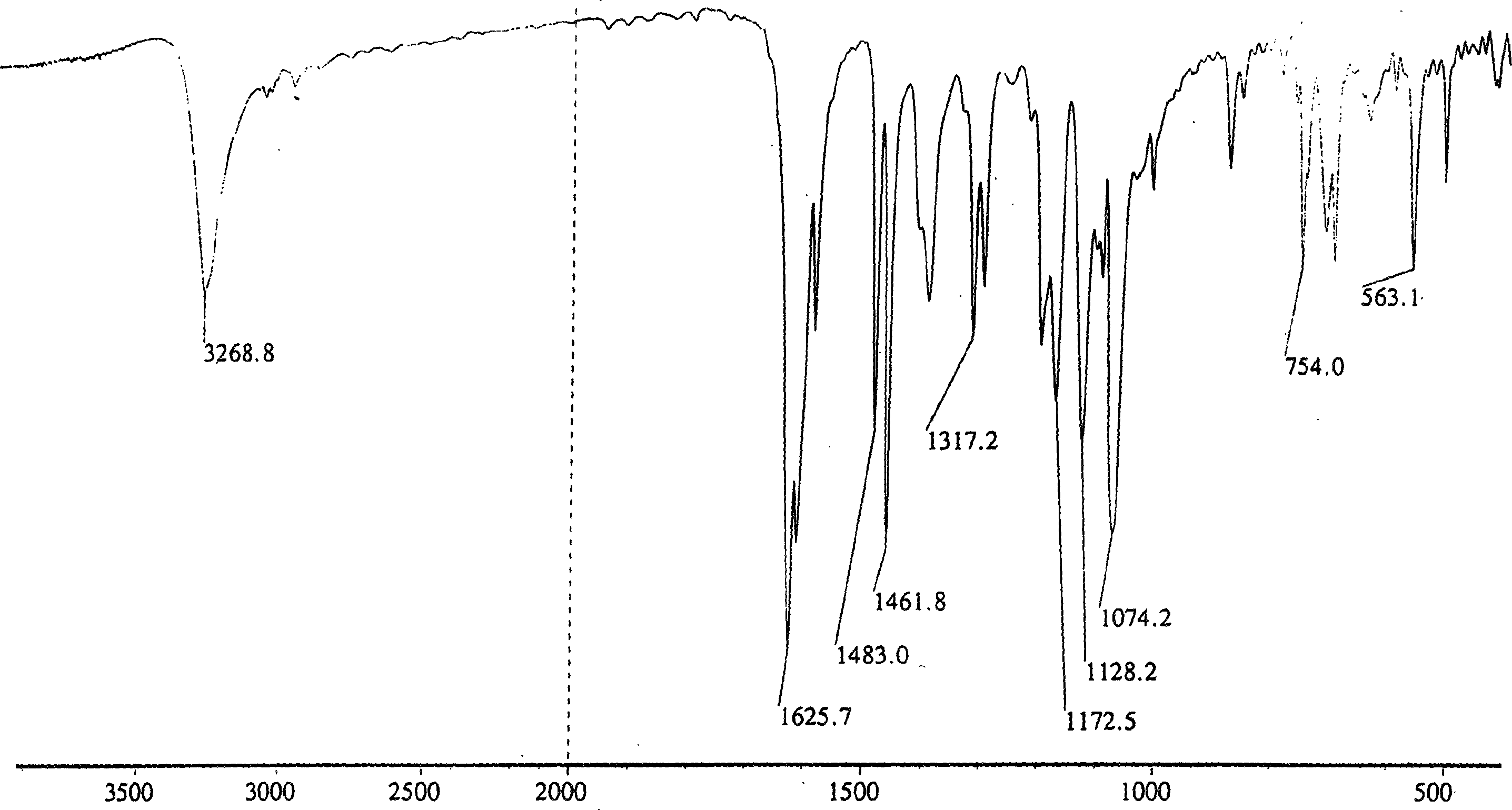

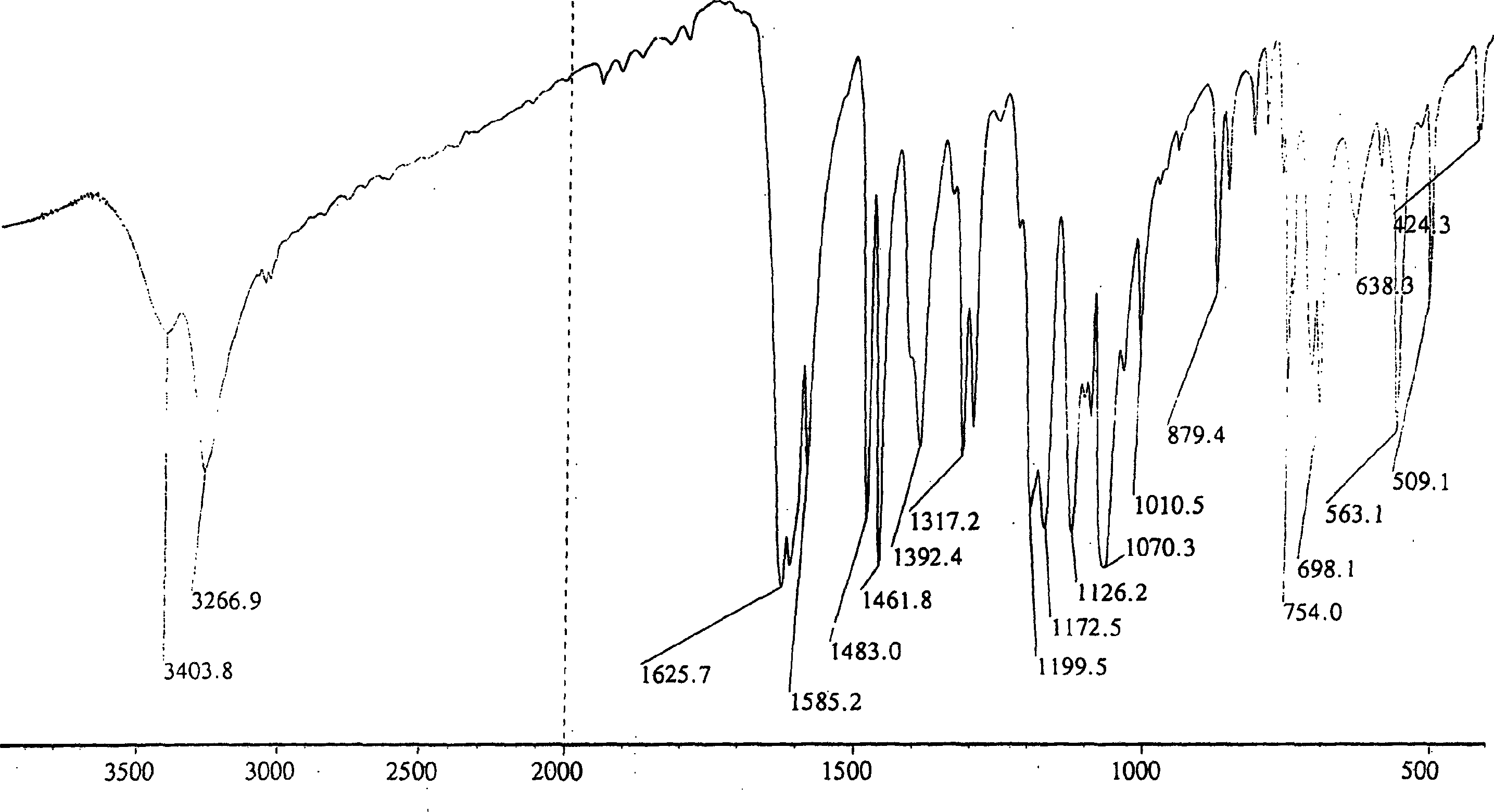

Image

Examples

Embodiment 1

[0048] Embodiment 1: purification 3-indoxyl salt (3-indoxyl sodium and 3-indoxyl potassium)

[0049] Add 25 grams of 3-indoxyl salt crude product (25%) into a 250 ml Erlenmeyer flask, add 40 ml of deoxygenated water, dissolve it at 90°C, cool to 40°C, crystallize, stir and suction filter to obtain 13.83 gram of filter cake, then dehydrated and dried, and its 3-indoxyl salt (containing crystal water) content was 82% after analysis.

Embodiment 2

[0050] Embodiment 2: purification 3-indoxylate sodium

[0051] Add 25 grams of 3-indoxyl sodium crude product (24%) into a 250 ml Erlenmeyer flask, add 25 ml of deoxygenated water, dissolve it at 100°C, cool to 50°C, crystallize, stir and suction filter to obtain 11.80 gram of filter cake, then dehydrated and dried, and its 3-indoxyl salt (containing crystal water) content was 80% after analysis.

Embodiment 3

[0052] Embodiment 3: purify 3-indoxylate potassium

[0053] Add 25 grams of 3-indoxyl potassium crude product (28%) into a 250 ml Erlenmeyer flask, add 125 ml of deoxygenated water, dissolve it at 80°C, cool to 20°C, crystallize, stir and suction filter to obtain 14.30 gram of filter cake, then dehydrated and dried, and its 3-indoxyl salt (containing crystal water) content was 81% after analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com