Sensor with permanent depth marks on connecting wires

A technology for connecting wires and sensors, which is applied in the field of sensors, can solve the problems of fading, hard to identify, easy to wear, etc., and achieve the effects of improving measurement accuracy, enhancing water resistance, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

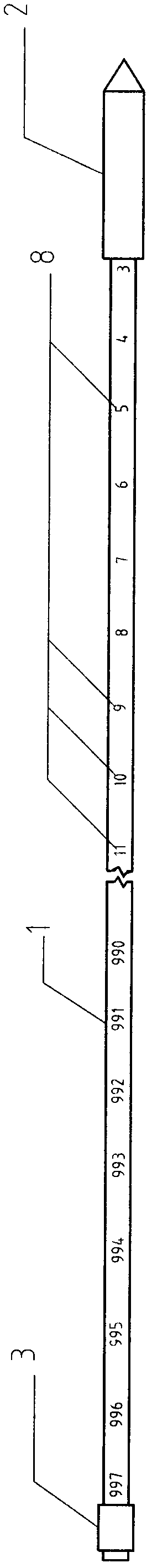

[0017] as attached figure 1 , attached figure 2 And attached image 3 As shown, an ultrasonic transducer with a permanent depth mark on the connecting wire. This example is an ultrasonic transducer shared by sending and receiving. The design uses a single-core coaxial shielded wire. For materials, print digital depth markings in decimeters every 10 centimeters on the surface of the quilt, such as the marking of 99.7m long connecting wires, starting from the top of the sensor as the first integral decimeter to 997 decimeters According to the corresponding depth, the numbers 3, 4, 5 ... 996, 997, etc. are spray printed, and then wrapped on the middle quilt with a transparent PVC-based outer quilt.

Embodiment 2

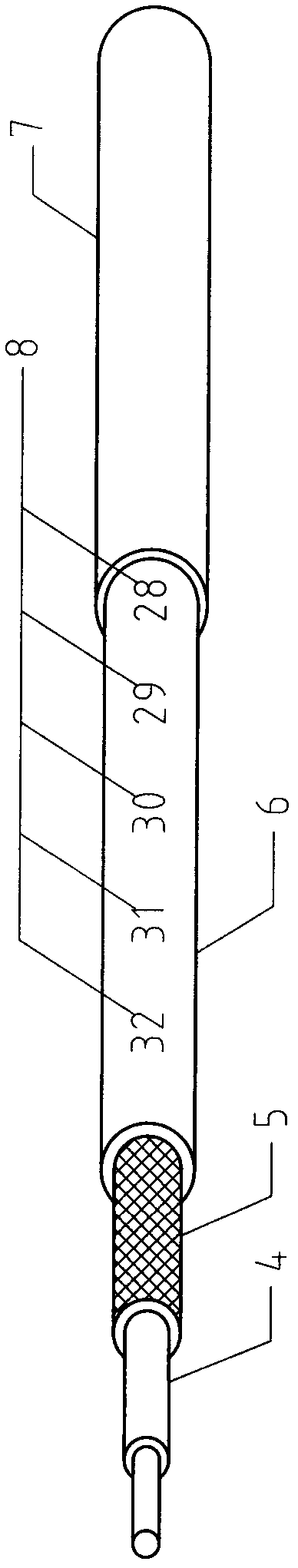

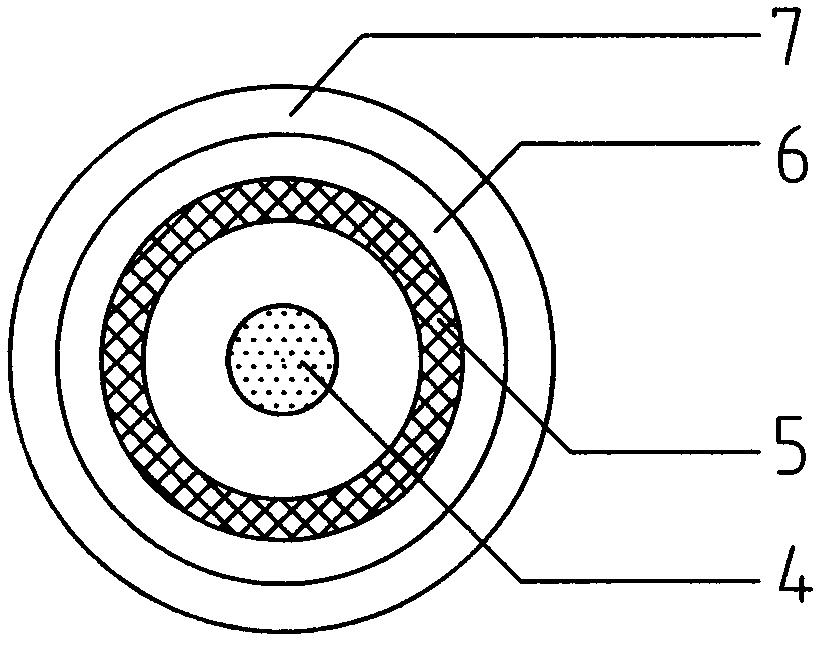

[0019] as attached Figure 4 As shown, an ultrasonic transducer with a permanent depth mark on the connecting wire. This example is an ultrasonic receiving transducer with a preamplifier. The design uses a three-core shielded wire, and the meter is used as the unit of measurement on the surface of the quilt. Print the digital depth mark, and then wrap the outer jacket with transparent PVC as the base material on the inner jacket.

[0020] All the other are with embodiment 1.

Embodiment 3

[0022] as attached Figure 5 Shown is a geophone with permanent depth markings on the connecting wires. The design adopts single-core coaxial shielded wire, and the center of the cable sheath is made of polyurethane base material. Every 25 cm, the digital depth mark is printed in centimeters, and then covered with a transparent polyurethane transparent film.

[0023] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com