Air-tightness detector

A detection machine and airtight technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., can solve the problem of limited space in the engine chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

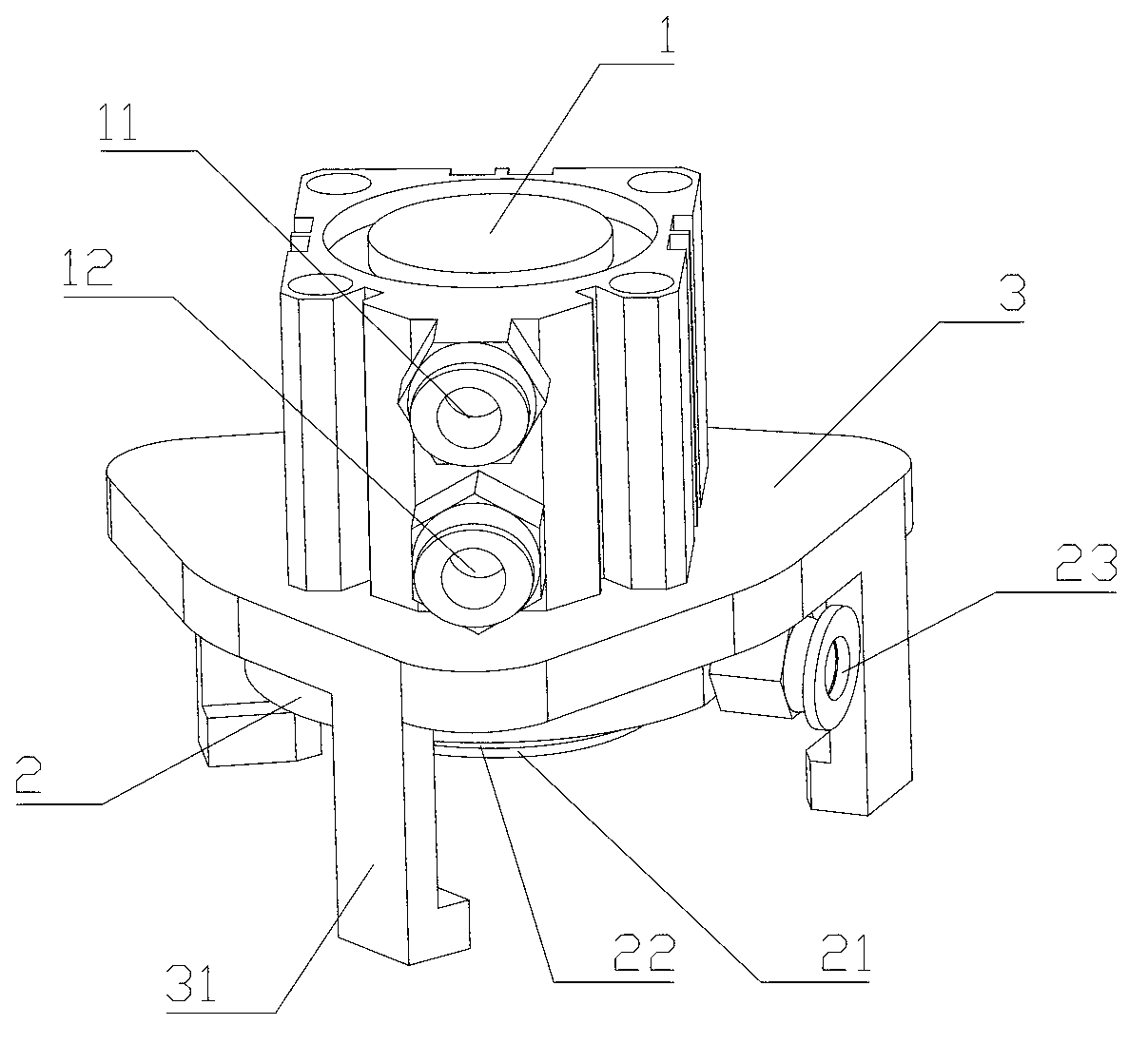

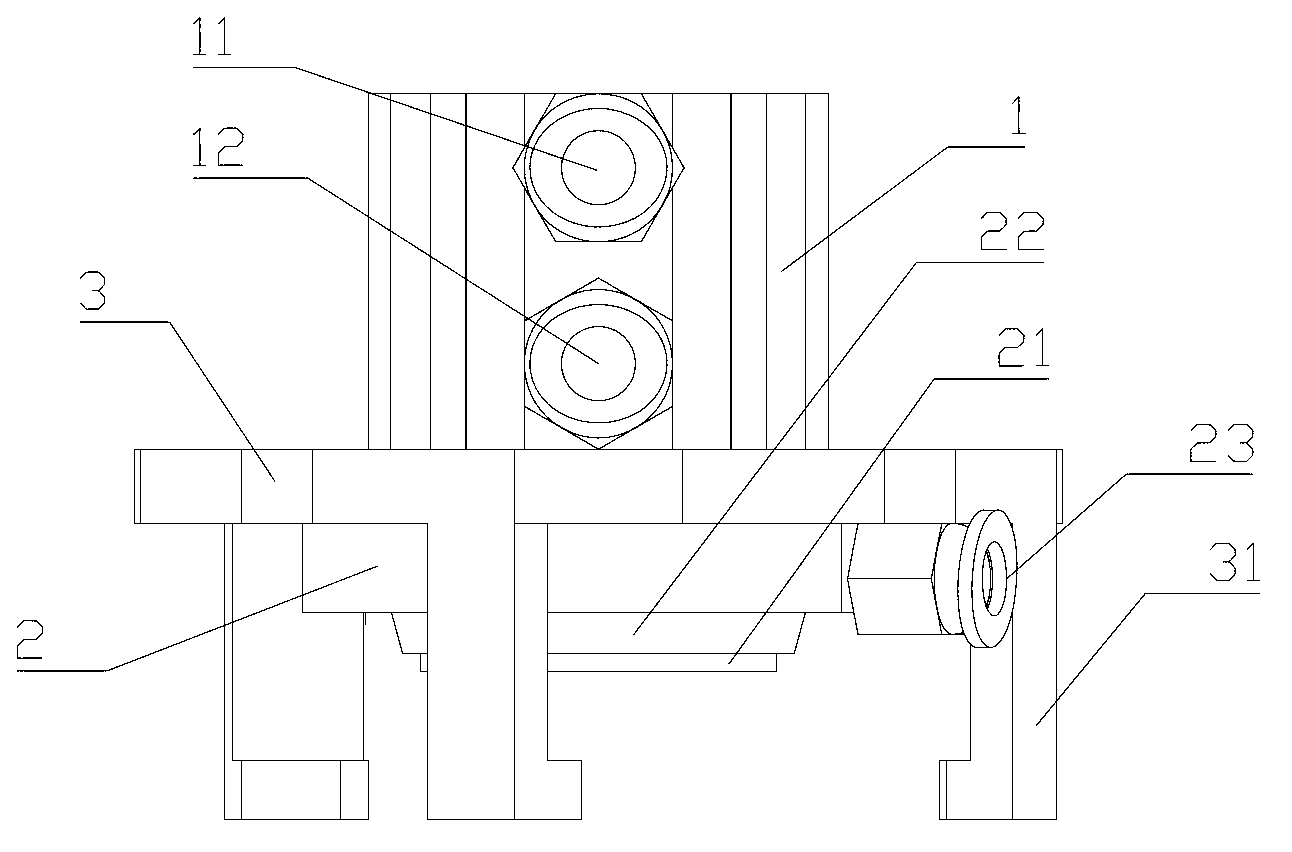

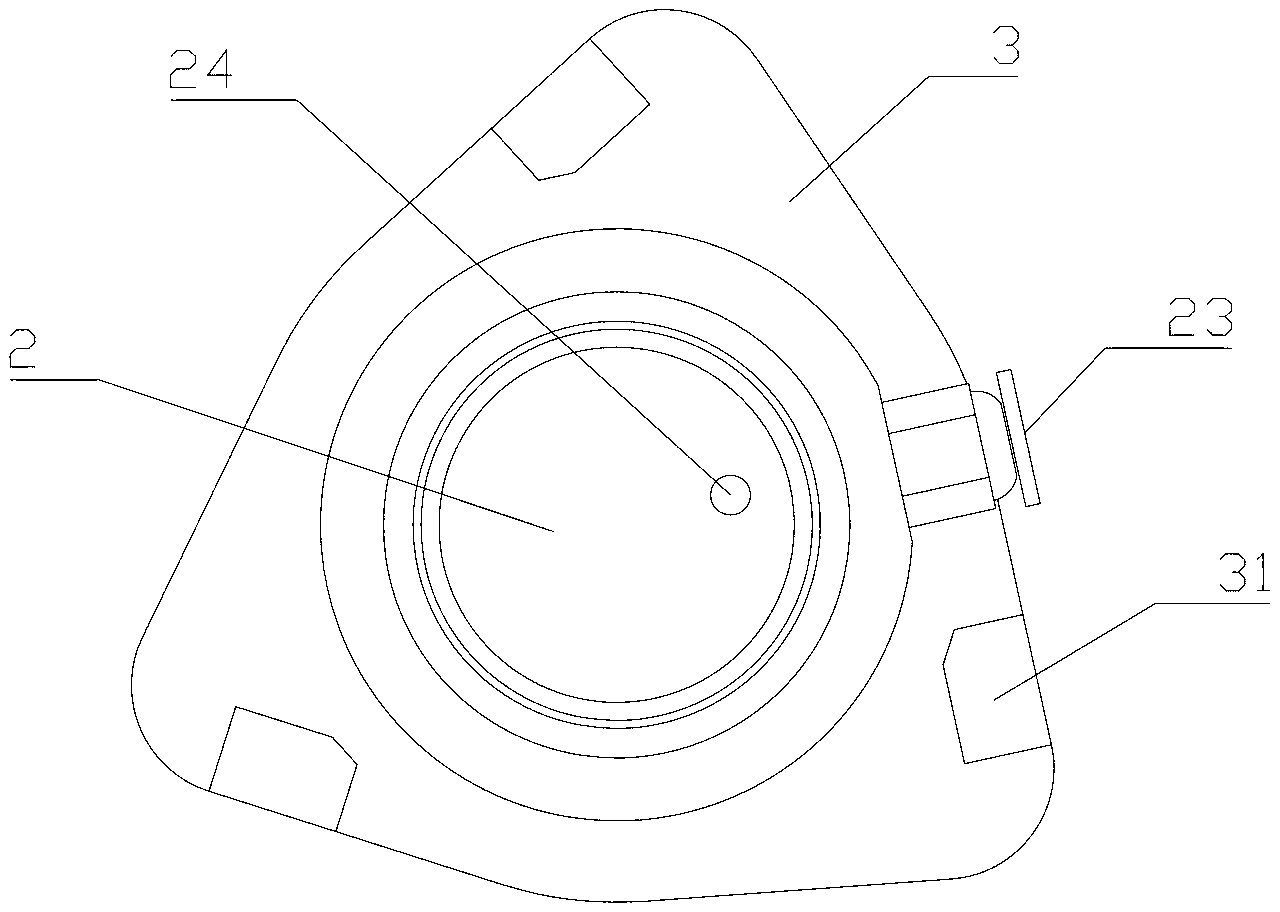

[0018] Such as Figure 1 to Figure 3 As shown, the air tightness testing machine includes a cylinder 1, and one end of the piston rod of the cylinder is provided with a chassis 2 that seals the catalytic converter, and the chassis 2 is provided with a gas delivery device for inputting the gas provided by the inflator into the catalytic converter. The structure also includes a pressure gauge for detecting the pressure change inside the catalytic converter after the filling is completed.

[0019] The chassis is provided with a step body 21 which is sealingly matched with the inlet and outlet ports of the catalytic converter, and a gasket 22 is provided on the step body. The air delivery structure includes an air inlet 23, an air inlet passage and an air outlet 24, the air inlet is arranged on the side wall of the chassis, the air outlet is arranged on the end face of the step body, and the air inlet passage is arranged on the side wall of the chassis. The air inlet and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com