TiO2 sensitive layer structure used for oxygen sensor and preparation method thereof

An oxygen sensor and sensitive layer technology, applied in the field of TiO2 sensitive layer structure, can solve the problems that the square structure cannot improve the surface to volume ratio, affect the sensor characteristics, and affect the accuracy, so as to suppress the generation of cracks and prevent cracks. The effect of spreading, reducing cracks, increasing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see figure 1 , conventional TiO 2 The sensitive layer is just a simple plane square, which is easily cracked by thermal stress under heating working conditions, which affects the electrical characteristics of the sensitive layer.

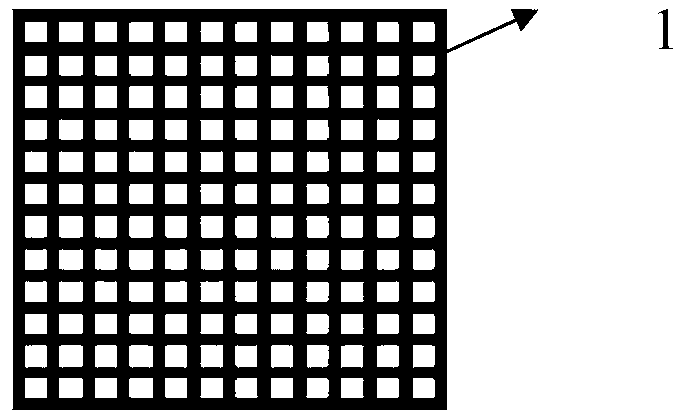

[0025] see figure 2 ,TiO 2 The sensitive layer structure suppresses the generation of cracks in the mesh wire 1 and the propagation of cracks in the mesh wire 1 through mesh treatment, effectively reducing the cracks caused by the thermal stress caused by the mismatch of thermal expansion coefficient in the mesh wire 1; the ratio of surface to volume improve, which is conducive to the adsorption of oxygen and thus increases the TiO 2 Sensitive layer sensitivity and reduced response time. The network cable 1 has a width of 2-4 μm, and the mesh formed by the vertical and horizontal network cables is a square with a side length of 4-8 μm; the outermost network cable is surrounded by a large square with a side length of 74-148 μm.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com