Water blocking cable with round aluminum conductor

A technology for aluminum conductors and cables, which is applied in the direction of insulating conductors/cables, power cables with shielding layers/conducting layers, etc., can solve the problem that the waterproof performance of cables has not reached a satisfactory level, and achieves water seepage prevention and convenient operation. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

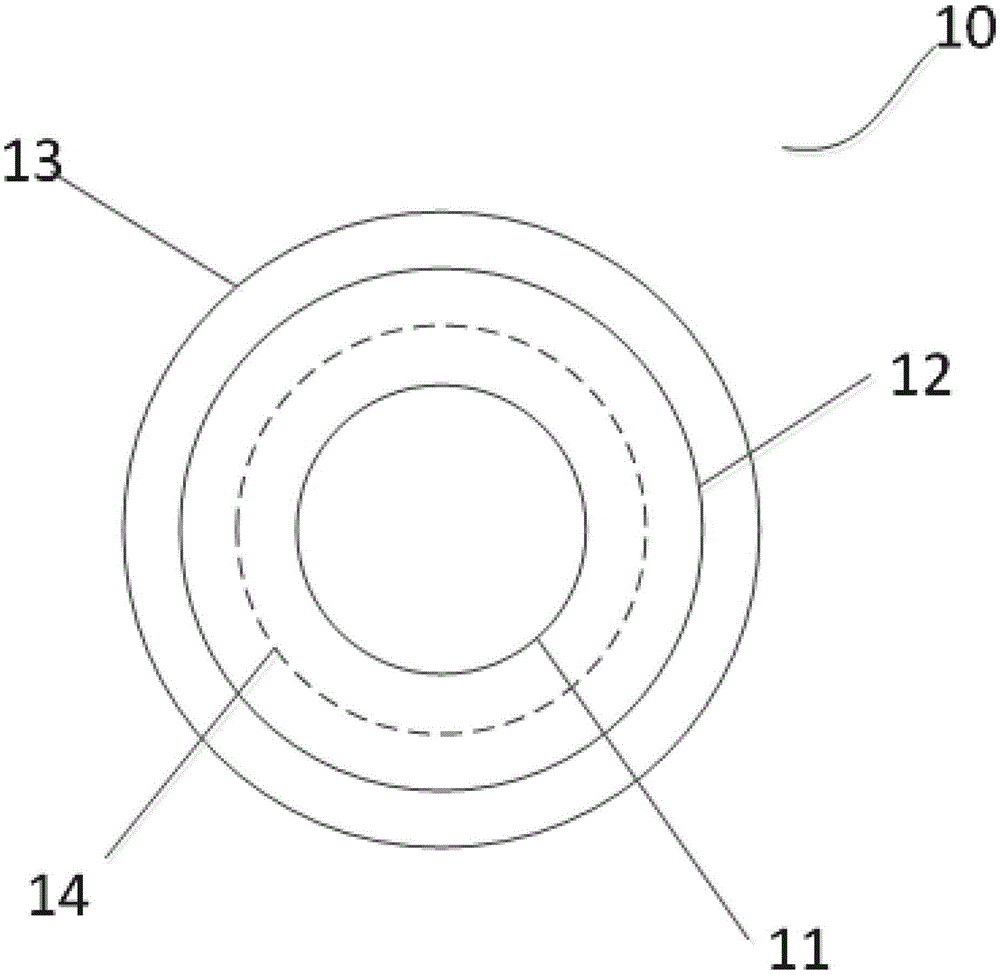

[0018] refer to figure 1 , The round aluminum conductor water-blocking cable 10 of the present invention adds three additional layers of structure to one end of the common core wire 11, so as to achieve the purpose of waterproofing and water-blocking. The three-layer structure is water-blocking yarn 12, single-sided insulating water-blocking tape 14, and semiconductive resistance water-binding tape 13.

[0019] Such as figure 1 As shown, the core wire 11 is covered by a multi-layer single-sided insulating water-blocking tape 14, and the water-blocking surface of the single-sided insulating water-blocking tape 14 faces the outside of the cable. Here, the purpose of the present invention can be achieved by using a single-sided insulating water-blocking tape, but the present invention is not limited to this, and double-sided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com