Bushing for mining explosion-proof dry-type transformer and production method for bushing

A dry-type transformer and production method technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, electrical components, etc., can solve the problems of long-term use danger, small contact area, large contact resistance, etc., and reduce production. Cost, process reduction, and effect of fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

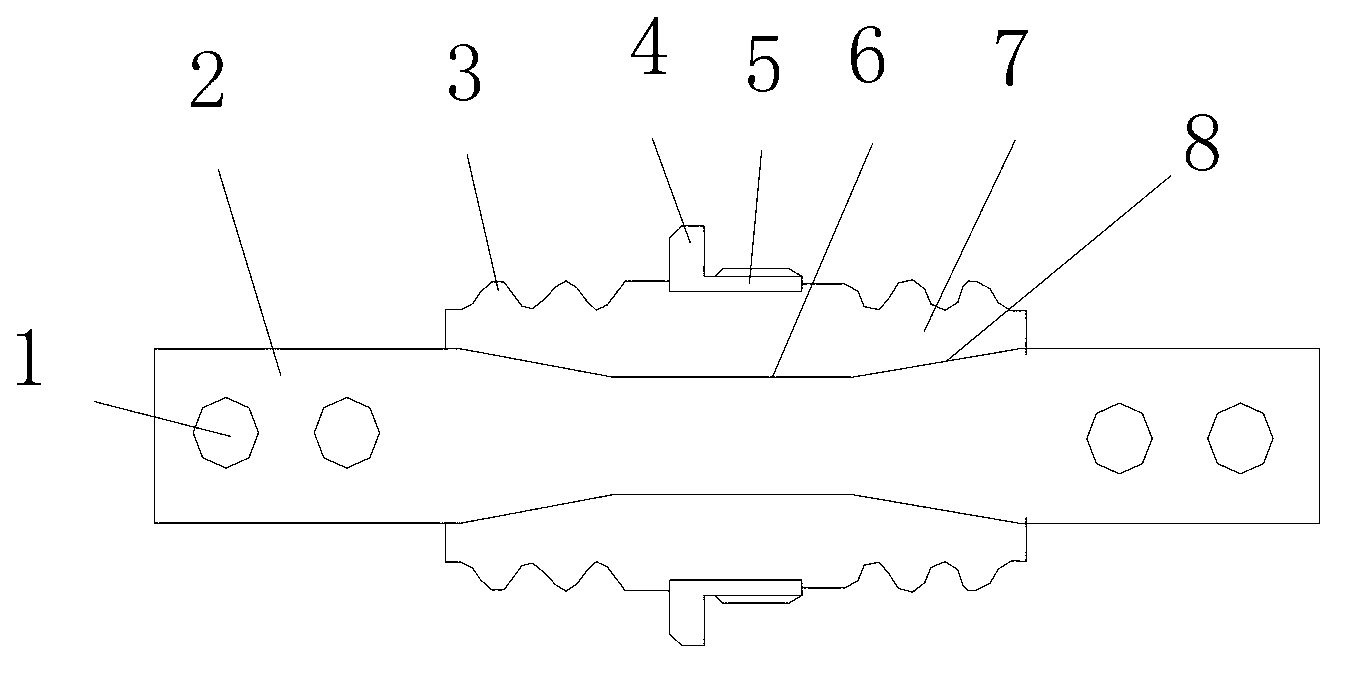

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Mine explosion-proof dry-type transformer bushing is characterized in that it includes a conductive rod 6, the conductive rod 6 is cylindrical, and the diameter of the middle part of the conductive rod 6 is smaller than the diameter of the two ends of the conductive rod 6, so A transition cone 8 is set between the middle part and the two ends of the conductive rod, and a circular flange is set on the conductive rod 6, and the circular flange is located in the middle of the conductive rod. The central axis of the flange and the axis of the conductive rod are on the same axis, and an insulating fixing block 7 is injection-molded between the conductive rod 6 and the circular flange. The transformer bushing of the present invention has a simple structure, is convenient for production and processing, and reduces In terms of production cost, the present invention does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com