Medium voltage power distribution equipment

A technology of power distribution equipment and equipment, applied in the direction of high-voltage/high-current switches, circuits, electric switches, etc., can solve problems such as complex current conduction functions, complex molding, and unreasonable industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

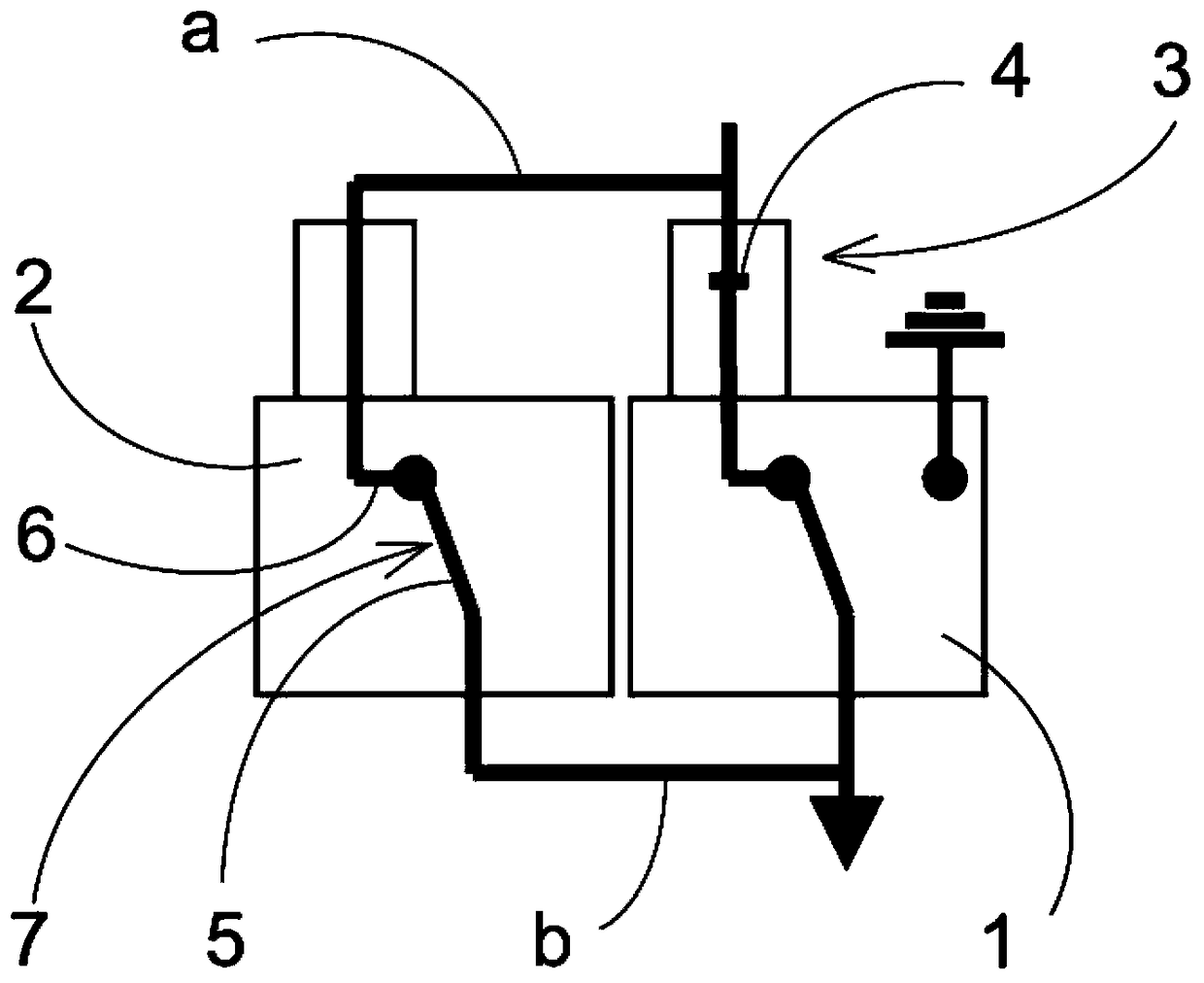

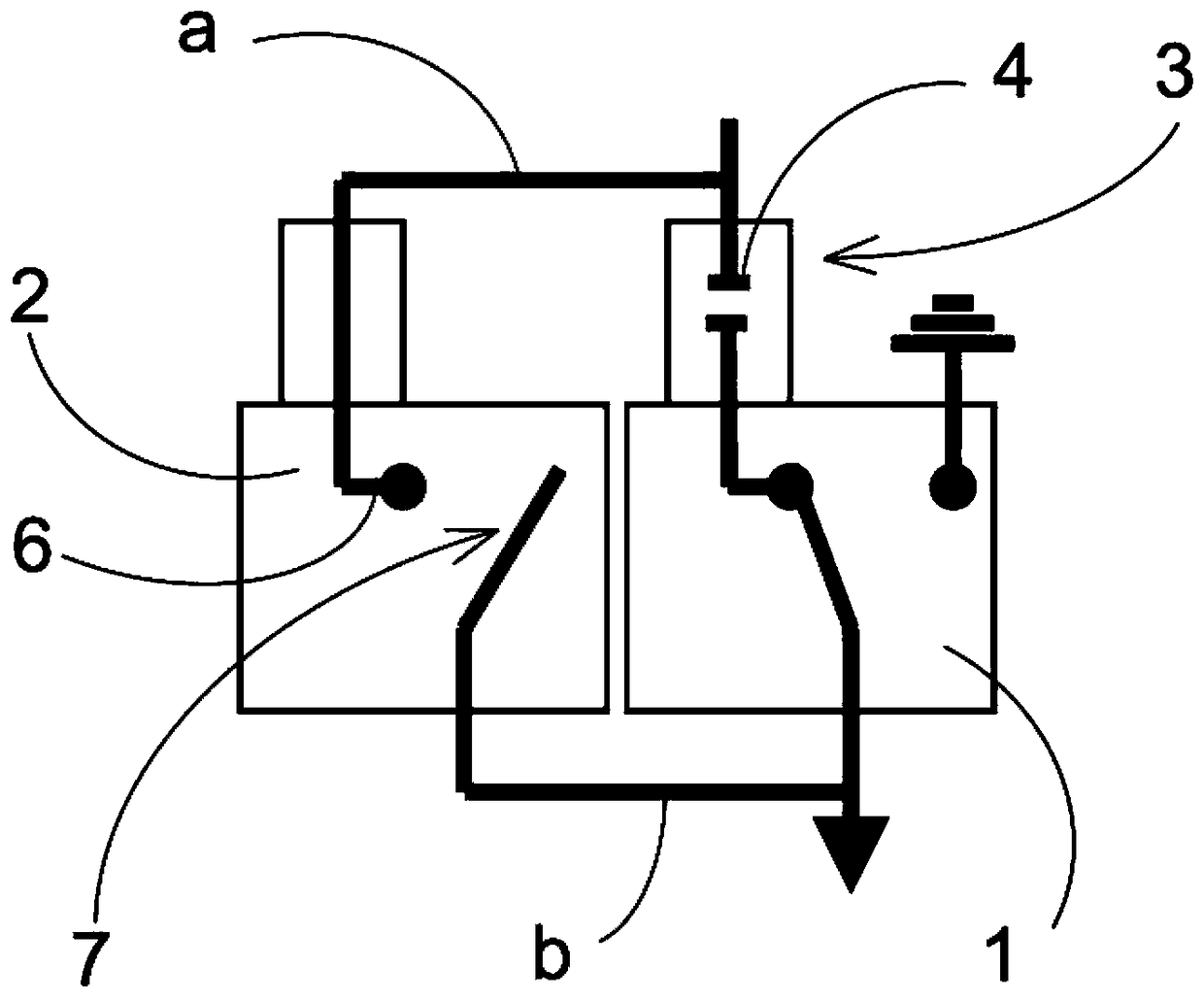

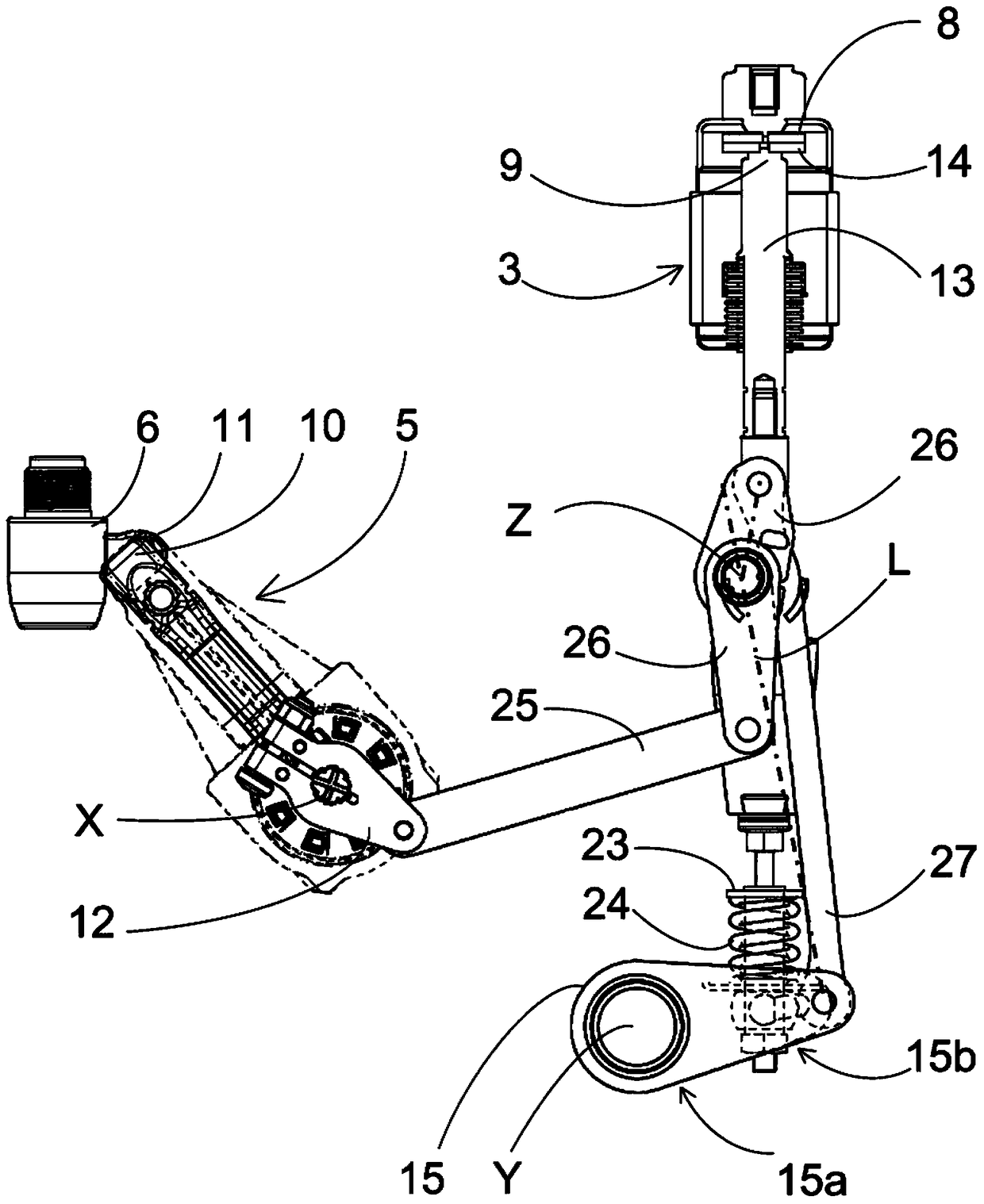

[0034] exist figure 1 and 2 In , there can be seen a multi-pole motorized switchgear comprising, for each pole, two switchboards 1, 2 mounted in parallel and electrically connected on one side to the first busbar 1a and on one side The opposite side is connected to the second busbar b.

[0035] The first switchboard 1 , located on the right in the figure, comprises in this particular embodiment a vacuum circuit breaker 3 comprising a vacuum box 4 connected in series with a disconnector 5 having two positions, respectively for the closed and grounded positions.

[0036] A second switchboard, located to the left of the first switchboard, includes a disconnect switch having two positions, a closed current flow position and an open position.

[0037] The two switchboards are mechanically connected so as to follow a specific sequence, which will be detailed below.

[0038] exist figure 1 , the equipment is in the closed position, and since the circuit breaker and disconnector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com