High-power light-emitting diode (LED) lamp and packaging method thereof

A technology of LED lamps and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of serious LED light scattering and inconsistent color temperature in space, and achieve the effects of good color temperature consistency, reduced light decay, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

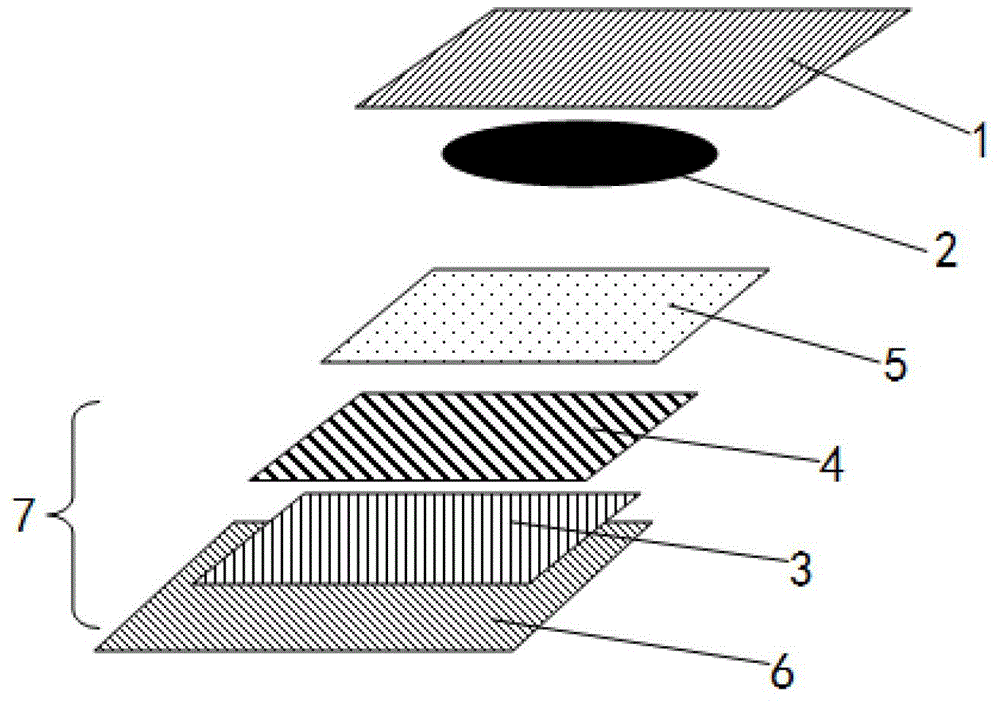

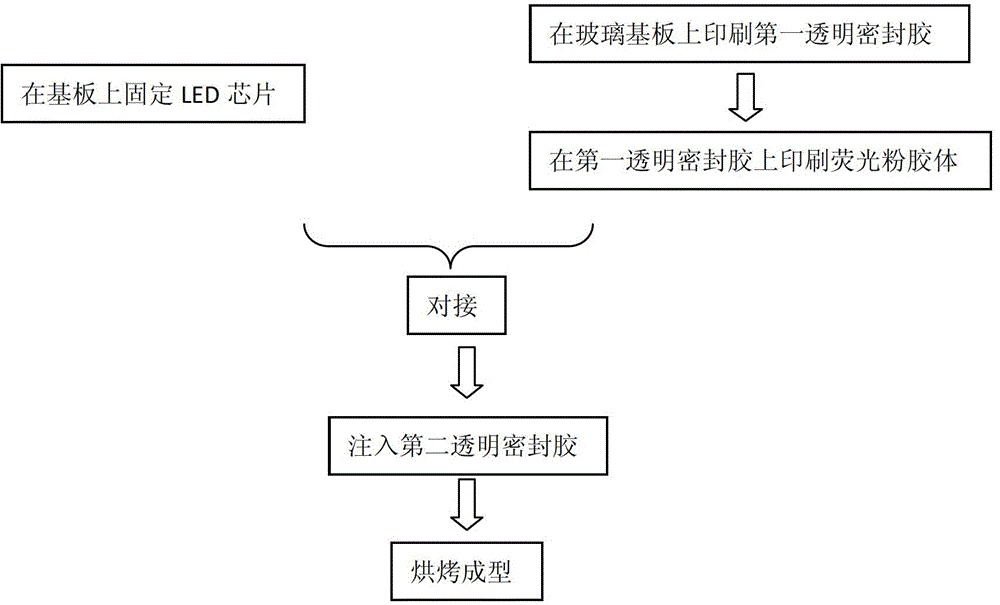

[0028] see figure 1 and 2 Shown, a kind of encapsulating method of high-power LED lamp of the present invention, concrete technological process is as follows:

[0029] Step 1: Fix the LED chip 2 to one side of the first substrate 1 with silver glue, then connect the LED chip 2 to the first substrate 1 with a gold wire, and then connect the first substrate 1 with the chip 2 at 40 ℃ heating for 80min, in this embodiment the first substrate 1 is a metal substrate;

[0030] The second step: apply the first transparent sealant 3 on the glass substrate 6 by screen printing to form a first transparent sealant layer with a light transmittance greater than 90%, pre-bake the glass substrate 6 at 80° C. Bake at ℃ for 3 hours to solidify and form a film;

[0031] Step 3: Print the fluorescent powder colloid 4 on the first transparent sealant layer by screen printing to form a fluorescent powder glue layer with a light transmittance greater than 90%, bake the glass substrate 6 at 80°C f...

Embodiment 2

[0035] A kind of encapsulating method of high-power LED lamp of the present invention, concrete technological process is as follows:

[0036] Step 1: Fix the LED chip 2 to one side of the first substrate 1 with a eutectic material, then connect the LED chip 2 to the first substrate 1 with a gold wire, and then connect the first substrate 1 with the chip 2 on the Heating at 40°C for 120 minutes, in this embodiment, the first substrate 1 is a ceramic substrate;

[0037] The second step: apply the first transparent sealant 3 on the glass substrate 6 by screen printing to form a first transparent sealant layer with a light transmittance greater than 90%, pre-bake the glass substrate 6 at 80° C. Bake at ℃ for 3 hours to solidify and form a film;

[0038] Step 3: Print the fluorescent powder colloid 4 on the first transparent sealant layer by screen printing to form a fluorescent powder glue layer with a light transmittance greater than 90%, bake the glass substrate 6 at 80°C for 1...

Embodiment 3

[0042] A kind of encapsulating method of high-power LED lamp of the present invention, concrete technological process is as follows:

[0043] Step 1: Fix the LED chip 2 to one side of the first substrate 1 with silver glue, then connect the LED chip 2 to the first substrate 1 with a gold wire, and then connect the first substrate 1 with the chip 2 at 40 ℃ heating for 100min, in this embodiment the first substrate 1 is a metal substrate;

[0044] The second step: apply the first transparent sealant 3 on the glass substrate 6 by screen printing to form a first transparent sealant layer with a light transmittance greater than 90%, pre-bake the glass substrate 6 at 80° C. Bake at ℃ for 3 hours to solidify and form a film;

[0045]Step 3: Print the fluorescent powder colloid 4 on the first transparent sealant layer by screen printing to form a fluorescent powder glue layer with a light transmittance greater than 90%, bake the glass substrate 6 at 80°C for 1 hour, and cure it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com