MMC (Modular Multi-level Converter) converter valve submodule device based on thyristor device and controlling method of submodule device

A control method and thyristor technology, applied in the output power conversion device, the conversion equipment without intermediate conversion to AC, the conversion of AC power input to DC power output, etc. It can reduce the complexity of control, reduce the number of series series, and increase the rated voltage and current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

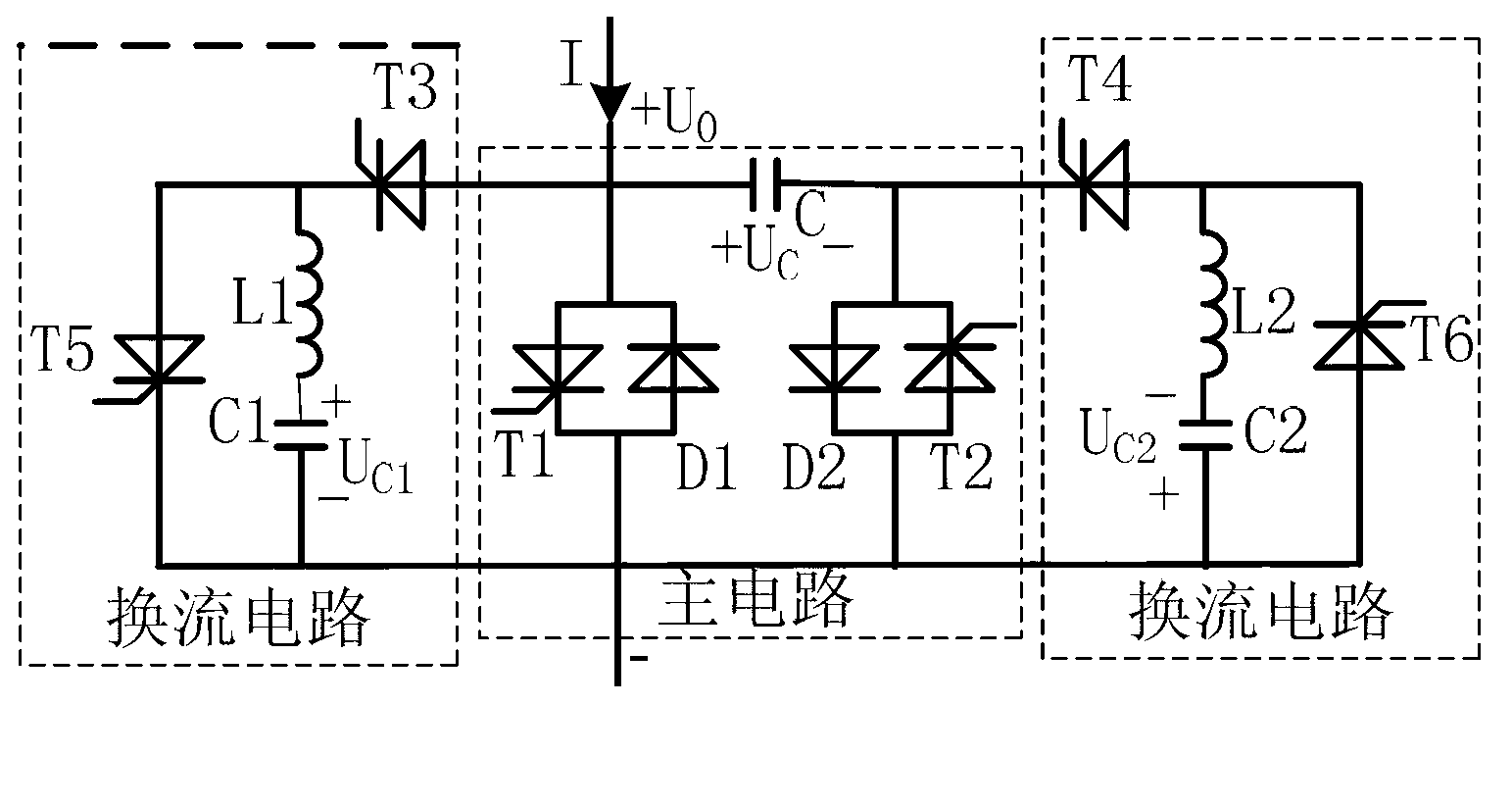

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

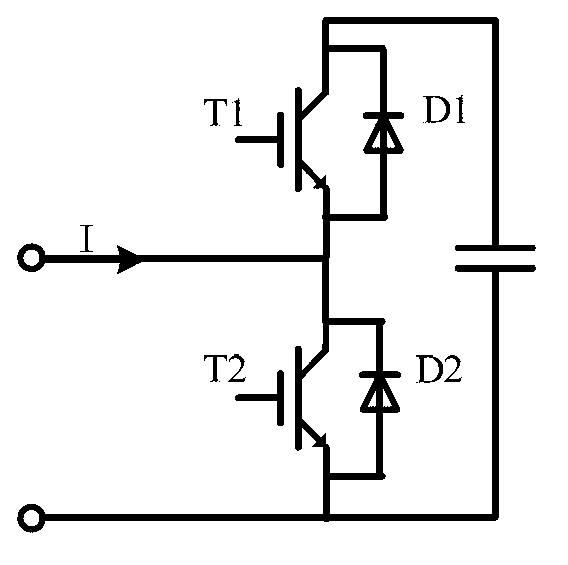

[0033] The topological structure of the MMC converter valve sub-module based on the thyristor device provided by the present invention is as follows: figure 2 As shown, it includes a main circuit and a forced commutation circuit connected in parallel with its two ends; the main circuit includes a thyristor unit I, a thyristor unit II and a capacitor C; both the thyristor unit I and the thyristor unit II are composed of a thyristor and a diode antiparallel to it .

[0034] The thyristor unit I is connected in parallel with the thyristor unit II; the capacitor C is connected between the thyristor unit I and the thyristor unit II.

[0035] The thyristor unit I includes a thyristor T1 and a diode D1 connected in antiparallel with it; the cathode of the thyristor T1 is connected to the anode of the diode D1, and the cathode...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap